Oxygen furnace steel method capable of improving jet velocity through preheated oxygen

A technology of jet velocity and oxygen flow, which is applied in the field of metallurgy, can solve problems such as the composition and temperature of the molten pool are uniform and slow, reduce the reaction speed of steel slag, and limit the intensity of oxygen stirring, so as to shorten the smelting cycle, strengthen the stirring ability, decarburization and decarburization Phosphorus efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

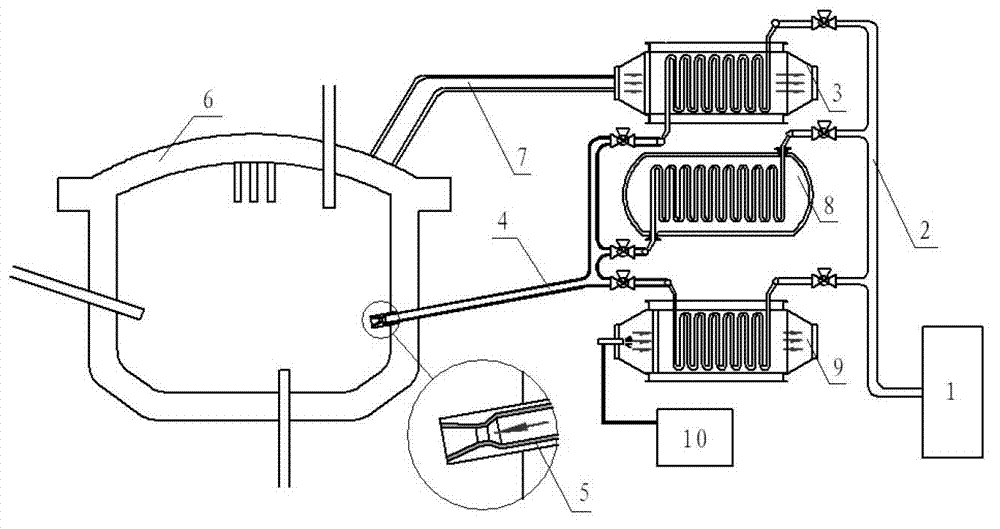

[0020] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

[0021] (1) The present invention is applied to the furnace wall oxygen lance of a 50-ton electric arc furnace, the Mach number of the nozzle is 2, and the flow rate of the oxygen lance is 1500Nm 3 / h, pressure 0.8MPa. The segmental control process of smelting is as follows:

[0022] Melting period: Oxygen flow rate is 1000Nm 3 / h, after the flue gas is preheated, the temperature of the incoming oxygen flow can reach 900K, and the jet flow velocity at the nozzle outlet can reach 840m / s. , increased by about 0.52m, the temperature and composition of the molten pool are fast and uniform, and the melting time of scrap steel is shortened by 0.3-0.8 minutes;

[0023] Decarburization period: oxygen supply flow rate is 2000Nm 3 / h, after the flue gas is preheated, the temperature of the incoming oxygen flow can reach 1200K, and the jet flow velocity a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com