Halogen-free flame retardant high-temperature elastomer plug material and its preparation method

An elastomer and high-temperature-resistant technology, which is applied in the field of halogen-free flame-retardant high-temperature-resistant elastomer plug material and its preparation, can solve the problems of high-temperature resistance, toughness, impact resistance and other unsatisfactory mechanical properties, and achieve excellent electrical insulation performance, high Flame retardant properties, good hand feeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

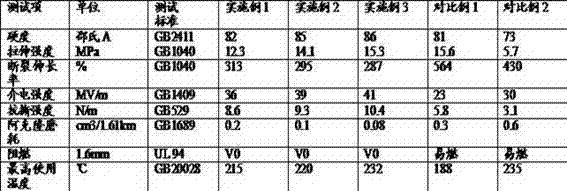

Examples

Embodiment 1

[0046]First put 20% (the following are weight percentages) polyphenylene ether LXR045, 30% hydrogenated styrene YH-503, and 10% polyolefin P740J into the high-mixer, turn on the power and rotate at high speed, and put 3% isophthalic acid from the upper port Phenol-bis(diphenyl phosphate) and 15% No. 46 white oil, mix for two minutes, then add 20% intumescent flame retardant, 0.5% lubricant, 0.5% antioxidant, 1% processing Modifier, mix for one minute; start discharging after mixing evenly, and twin-screw granulation. The temperature setting of each zone of the screw is: 190°C for zone 1, 210°C for zone 2, 220°C for zone 3, 230°C for zone 4, 230°C for zone 5, 220°C for zone 6, 220°C for zone 7, 210°C for zone 8, 200°C for zone 9 , 200°C in the tenth zone, 200°C in the eleventh zone, and 190°C at the head. The screw speed is 150rpm (rotation per minute). Among them, the first to second districts are the material conveying section, the third to fifth districts are the melting a...

Embodiment 2

[0048] First put 25% (the following are weight percentages) polyphenylene ether LXR045, 20% hydrogenated styrene YH-503, and 15% polyolefin P740J into the high-mixer, turn on the power and mix at high speed, and put 3% isophthalic acid from the upper port Phenol-bis(diphenyl phosphate) and 20% No. 46 white oil, mix for two minutes, then add 15% intumescent flame retardant, 0.5% lubricant, 0.5% antioxidant, 1% processing Modifier, mix for one minute; start discharging after mixing evenly, and twin-screw granulation. The temperature setting of each zone of the screw is: 190°C for zone 1, 220°C for zone 2, 230°C for zone 3, 230°C for zone 4, 230°C for zone 5, 220°C for zone 6, 220°C for zone 7, 210°C for zone 8, 200°C for zone 9 , 200°C in the tenth zone, 200°C in the eleventh zone, and 190°C at the head. The screw speed is 150rpm (rotation per minute).

Embodiment 3

[0050] First put 30% (the following are weight percentages) polyphenylene ether LXR045, 30% hydrogenated styrene YH-503, and 5% polyolefin P740J into the high-mixer, turn on the power and mix at high speed, and put 8% isophthalic acid from the upper port Phenol-bis(diphenyl phosphate) and 15% No. 46 white oil, mix for two minutes, then add 10% intumescent flame retardant, 0.5% lubricant, 0.5% antioxidant, 1% processing Modifier, mix for one minute; start discharging after mixing evenly, and twin-screw granulation. The temperature setting of each zone of the screw is: 200°C for zone 1, 220°C for zone 2, 230°C for zone 3, 240°C for zone 4, 240°C for zone 5, 230°C for zone 6, 220°C for zone 7, 210°C for zone 8, 210°C for zone 9 , 200°C in the tenth zone, 200°C in the eleventh zone, and 200°C at the head. The screw speed is 130rpm (rotation per minute).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com