Copolymer-sylvite composite film material and its preparation method

A technology of a copolymer and a composite membrane, which is applied in the field of composite membrane materials and their preparation, achieves the effects of simple and easy preparation process, convenient for large-scale industrial production, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Polyvinylidene fluoride-hexafluoropropylene copolymer (PVDF-HFP): potassium carbonate (K 2 CO 3 ), weigh the raw materials according to their mass ratio of 0.7:0.3, place the weighed raw materials in a nylon ball mill tank, use absolute ethanol as the medium, and ball mill them on a conventional ball mill for 16 hours, take out the milled slurry and Dry in a constant temperature drying oven at 80°C to form a mixed powder; add 10ml of organic solvent N, N-dimethylformamide (DMF) to the dried mixed powder to obtain a mixed solution; place the mixed solution on a magnetic stirrer Heat to 50°C and stir to dissolve the PVDF-HFP completely; then use an ultrasonic oscillator to vibrate until potassium carbonate (K 2 CO 3) is uniformly dispersed in the mixed solution to obtain a composite solution, and then the obtained composite solution is poured on a flat glass sheet cleaned by deionized water and absolute ethanol and cast evenly; the flat glass sheet loaded with the compo...

Embodiment 2

[0040] Weigh polyvinylidene fluoride-hexafluoropropylene copolymer (PVDF-HFP): potassium carbonate, and weigh the raw materials according to their mass ratio of 0.8:0.2, put the weighed raw materials in a nylon ball mill tank, and use absolute ethanol as the medium , milled on a conventional ball mill for 6 hours, the slurry after ball milling was taken out and dried in a constant temperature drying oven at 80°C to form a mixed powder; 15ml of organic solvent N,N-dimethyl was added to the dried mixed powder formamide (DMF) to obtain a mixed solution; heat the mixed solution to 60°C on a magnetic stirrer and stir to completely dissolve PVDF-HFP; then ultrasonically oscillate to K 2 CO 3 Disperse evenly in the mixed solution to obtain a composite solution, then pour the obtained composite solution on a flat glass sheet cleaned by deionized water and absolute ethanol and make it uniformly cast; place the flat glass sheet loaded with the composite solution Bake in a constant temp...

Embodiment 3

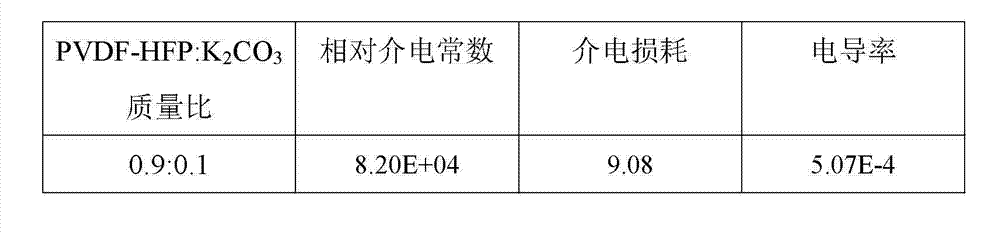

[0044] Weigh polyvinylidene fluoride-hexafluoropropylene copolymer (PVDF-HFP): potassium carbonate, and weigh the raw materials according to their mass ratio of 0.9:0.1, put the weighed raw materials in a nylon ball mill tank, and use absolute ethanol as the medium , milled on a conventional ball mill for 10 hours, and the milled slurry was taken out and dried in a constant temperature drying oven at 80°C to form a mixed powder; 20ml of organic solvent N,N-dimethyl was added to the dried mixed powder formamide (DMF) to obtain a mixed solution; heat the mixed solution to 70°C on a magnetic stirrer and stir to completely dissolve PVDF-HFP; then ultrasonically oscillate to K 2 CO 3 Disperse evenly in the mixed solution to obtain a composite solution, then pour the obtained composite solution on a flat glass sheet cleaned by deionized water and absolute ethanol and make it uniformly cast; place the flat glass sheet loaded with the composite solution Bake in a constant temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com