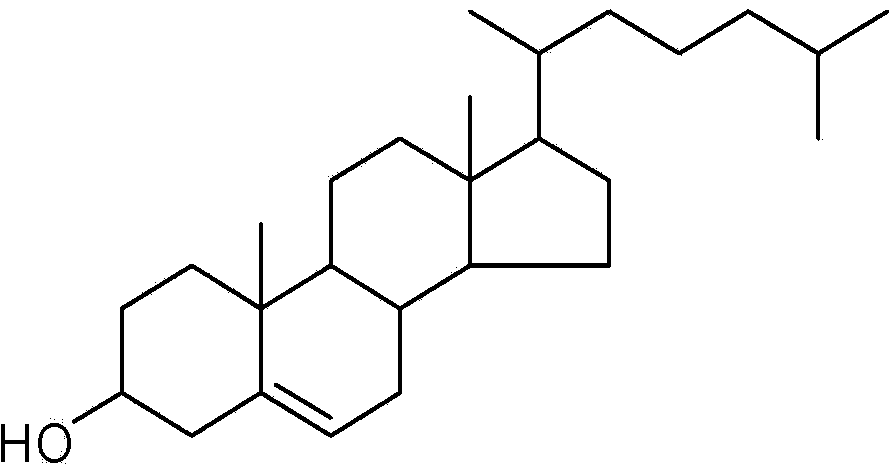

Method for separating cholesteryl ester from lanolin

A technology of cholesteryl ester and lanolin, which is applied in the field of chemical engineering, can solve the problems of low cholesteryl ester content, inability to obtain cholesteryl ester, and high energy consumption, and achieve the effects of simple process, high selective separation ability, and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

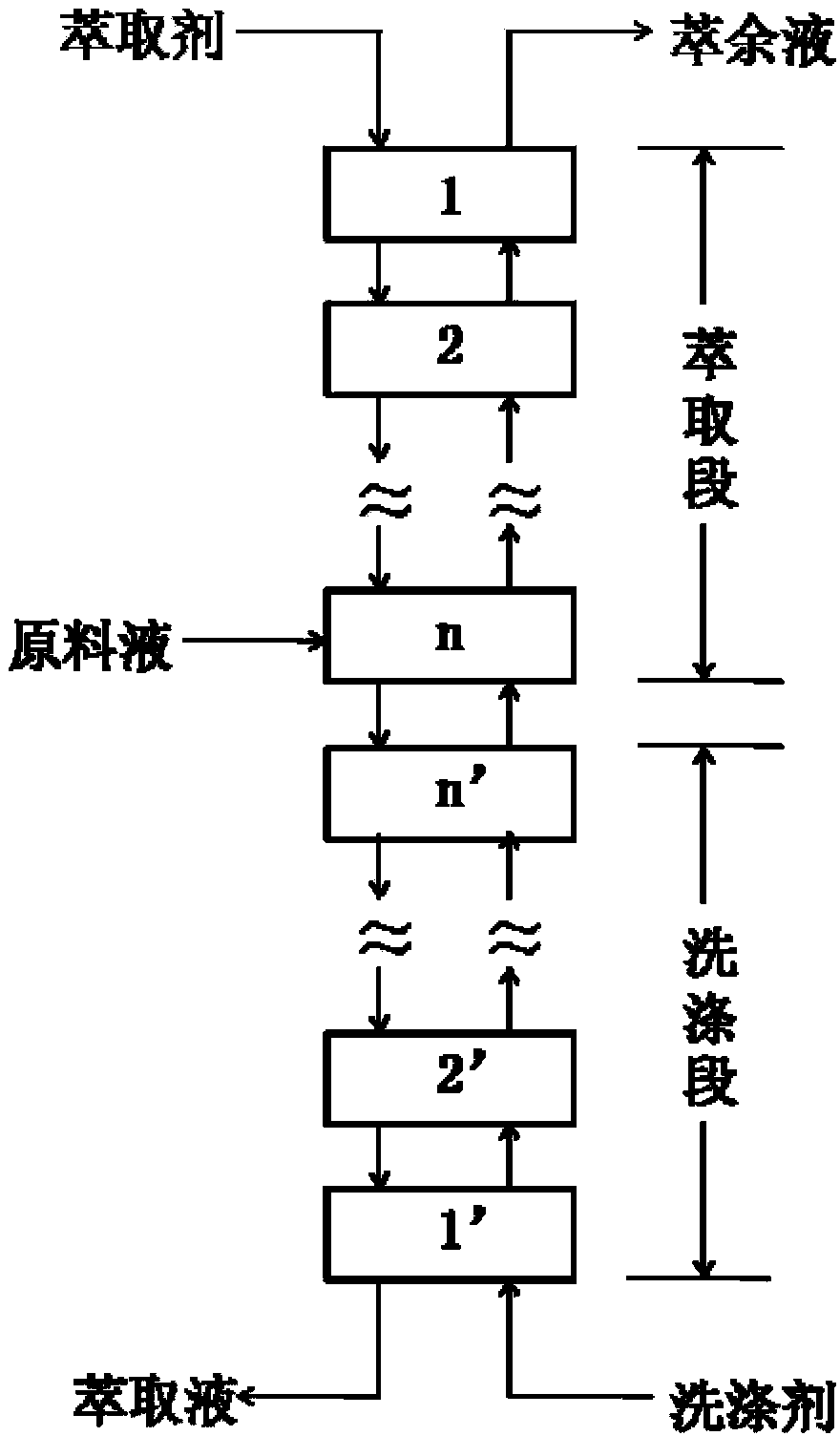

Embodiment 1

[0032] Lanolin (the mass percentage composition of cholesteryl ester is 25%) is dissolved in normal hexane and is made into the raw material liquid that lanolin total concentration is 10 g / liter, is extraction agent with acetonitrile, is washing agent with normal hexane, extraction agent, The flow ratio of detergent and raw material solution is 30:2:1, at 40°C figure 2 Fractional extraction is carried out in the fractionation extraction device shown (there are 10 stages in the extraction section and 10 stages in the washing section). The fractionation extraction is divided into an extraction section and a washing section. The last stage of the extraction section enters the fractionation extraction system, the detergent enters the fractionation extraction system from the first stage of the washing section, and the raw material liquid is combined into the extraction section at the last stage of the extraction section, and the extraction phase and the washing phase are subjected t...

Embodiment 2

[0034]Lanolin (the mass percentage composition of cholesteryl ester is 25%) is dissolved in n-hexane and is made into the raw material liquid that lanolin total concentration is 100 g / liter, with N-methylpyrrolidone as extractant, with n-hexane as detergent , the flow ratio of extractant, detergent and raw material solution is 50:20:1, at 30°C figure 2 Fractional extraction is carried out in the fractionation extraction device shown (there are 10 stages in the extraction section and 10 stages in the washing section). The fractionation extraction is divided into an extraction section and a washing section. The last stage of the extraction section enters the fractionation extraction system, the detergent enters the fractionation extraction system from the first stage of the washing section, and the raw material liquid is combined into the extraction section at the last stage of the extraction section, and the extraction phase and the washing phase are subjected to multi-stage cou...

Embodiment 3

[0036] Lanolin (the mass percentage composition of cholesteryl ester is 25%) is dissolved in cyclohexane and is made into the raw material liquid that lanolin total concentration is 0.5 g / liter, with 1,2-propanediol as extraction agent, with cyclohexane as The flow ratio of detergent, extractant, detergent, and raw material solution is 20:2:1, at 20°C figure 2 Fractional extraction is carried out in the fractionation extraction device shown (there are 10 stages in the extraction section and 10 stages in the washing section). The fractionation extraction is divided into an extraction section and a washing section. The last stage of the extraction section enters the fractionation extraction system, the detergent enters the fractionation extraction system from the first stage of the washing section, and the raw material liquid is combined into the extraction section at the last stage of the extraction section, and the extraction phase and the washing phase are subjected to multi-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com