A kind of composite film and preparation method thereof

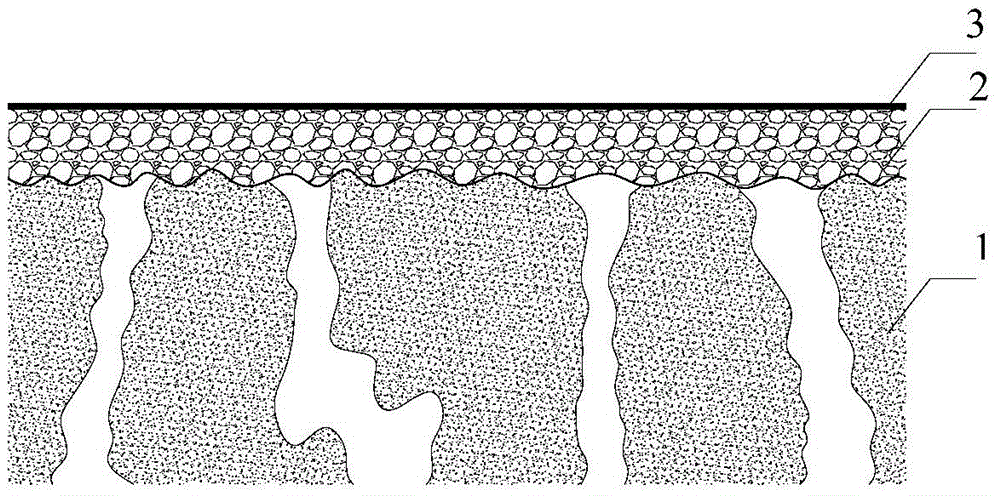

A composite membrane and supporting membrane technology, applied in the field of membrane materials, can solve the problems of easy peeling, poor bonding effect between the intermediate layer and the separation layer, etc., and achieve the effects of improving peeling strength, improving selective separation performance, and increasing bonding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

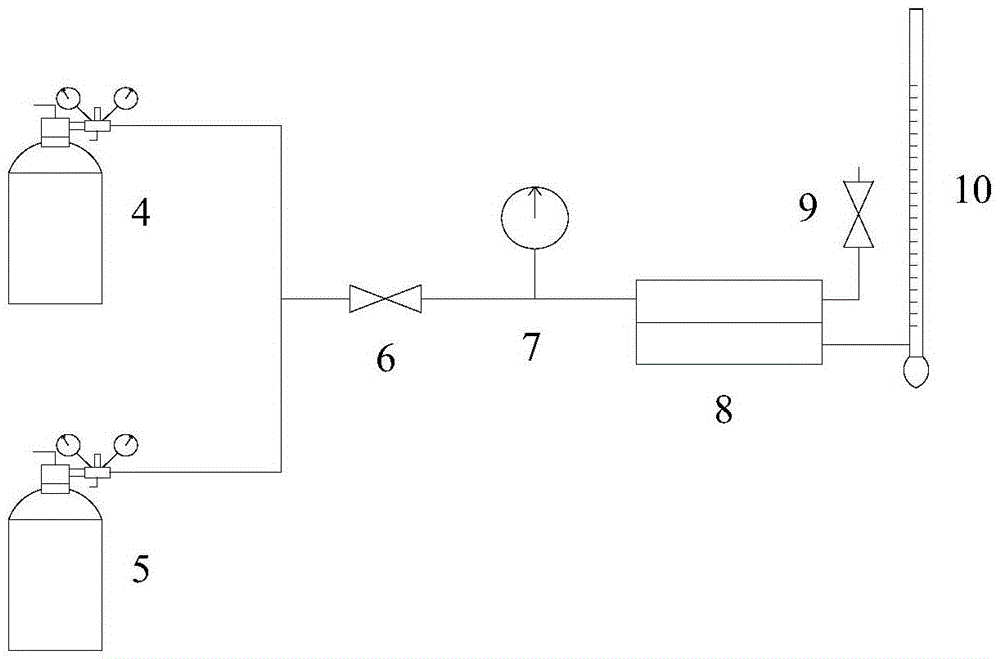

[0046] (1) Dissolve polyether copolyamide (PEBA) in a mixed solvent of ethanol / water (ethanol:water=7:3) to form a 1wt% PEBA solution, and place it for 24 hours for defoaming;

[0047] (2) After the PAN base film is washed with deionized water, spread it on a glass plate. After wiping off the moisture on the film surface, pour the 50°C PEBA solution in step (1) on the film surface, and shake the glass so that the film surface can be touched. After entering the solution, it was dried vertically in the shade for 10 minutes, and dried in an oven at 70°C for 10 minutes to remove the solvent to obtain a PAN / PEBA (1wt%) composite film.

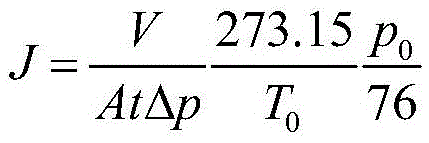

[0048] Using the above method to test the composite membrane against pure CO 2 and N 2 The permeation performance and separation performance, the results are shown in Table 1.

Embodiment 2

[0050] A PEBA solution at 50° C. was prepared according to the method in Example 1, wherein the concentration of PEBA in the solution was 3 wt%.

[0051] After the PAN base film is washed with deionized water, spread it on a glass plate. After wiping off the moisture on the film surface, pour the prepared PEBA solution on the film surface. Shake the glass so that the film surface can touch the solution and dry it vertically for 10 minutes. , and dried in an oven at 70°C for 10 minutes to remove the solvent to obtain a PAN / PEBA (3wt%) composite film.

[0052] Using the above method to test the composite membrane against pure CO 2 and N 2 The permeation performance and separation performance, the results are shown in Table 1.

Embodiment 3

[0054] A PEBA solution at 50° C. was prepared according to the method in Example 1, wherein the concentration of PEBA in the solution was 2 wt%.

[0055] After the PAN base film is washed with deionized water, spread it on a glass plate. After wiping off the moisture on the film surface, pour the prepared PEBA solution on the film surface. Shake the glass so that the film surface can touch the solution and dry it vertically for 10 minutes. , and dried in an oven at 70°C for 10 minutes to remove the solvent to obtain a PAN / PEBA (2wt%) composite film.

[0056] Using the above method to test the composite membrane against pure CO 2 and N 2 The permeation performance and separation performance, the results are shown in Table 1.

[0057] Table 1.

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com