Method for preparing yttrium-barium-copper-oxygen high-temperature superconducting film

A high-temperature superconducting and yttrium-barium-copper-oxygen technology is applied in the field of preparation of high-temperature superconducting thin films to achieve low preparation costs, be conducive to industrial production, and be environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Weigh yttrium acetate, barium acetate and copper acetate to be 0.005mol, 0.01mol and 0.015mol respectively, mix yttrium acetate, barium acetate and copper acetate and dissolve them in 100ml deionized water containing 10mol% acetic acid to form Solution, the solution that makes Y, Ba and Cu three kinds of metal total ion concentrations is 0.3mol / L;

[0027] (2) Stir the acetate solution prepared in step (1) for 1 h with a magnetic stirrer, and then use a rotary evaporator to evaporate the solvent to obtain a gel;

[0028] (3) Add the gel prepared in the step (2) into 50ml of methanol, stir with a magnetic stirrer for 0.5h, and then use a rotary evaporator to evaporate the solvent to further remove impurities such as moisture to obtain a pure gel ;

[0029] (4) the gel that described step (3) is made joins in the mixed solution of 15ml triethanolamine and 5ml terpineol, makes the solution that Y, Ba and Cu three kinds of metal total ion concentrations are 1.5mol / L ;...

Embodiment 2

[0036] (1) Weigh yttrium acetate, barium acetate and copper acetate to be 0.01mol, 0.02mol and 0.03mol respectively, mix yttrium acetate, barium acetate and copper acetate and dissolve in 100ml deionized water containing 20mol% acetic acid to form a solution , making Y, Ba and Cu three kinds of metal total ion concentrations are the solution of 0.6mol / L;

[0037](2) Stir the acetate solution prepared in step (1) for 2 hours with a magnetic stirrer, and then use a rotary evaporator to remove the solvent to obtain a gel;

[0038] (3) Add the gel prepared in the step (2) into 100ml of methanol, stir it with a magnetic stirrer for 1 hour, and then use a rotary evaporator to remove the solvent to further remove impurities such as water to obtain a pure gel;

[0039] (4) the gel that described step (3) is made is added in the mixed solution of 30ml triethanolamine and 10ml terpineol, makes the solution that Y, Ba and Cu three kinds of metal total ion concentrations are 1.5mol / L ; ...

Embodiment 3

[0046] (1) Weigh yttrium acetate, barium acetate and copper acetate to be 0.015mol, 0.03mol and 0.045mol respectively, mix yttrium acetate, barium acetate and copper acetate and dissolve in 100ml deionized water containing 30mol% acetic acid to form a solution , making Y, Ba and Cu three kinds of metal total ion concentration is the solution of 0.9mol / L;

[0047] (2) The acetate solution prepared in step (1) was stirred for 3 hours by a magnetic stirrer, and then the solvent was evaporated by a rotary evaporator to obtain a gel;

[0048] (3) Add the gel prepared in the step (2) into 100ml of methanol, stir it with a magnetic stirrer for 1.5h, and then use a rotary evaporator to evaporate the solvent to further remove impurities such as water to obtain a pure gel ;

[0049] (4) the gel that described step (3) is made is added in the mixed solution of 30ml triethanolamine and 10ml terpineol, makes the solution that Y, Ba and Cu three kinds of metal total ion concentrations are ...

PUM

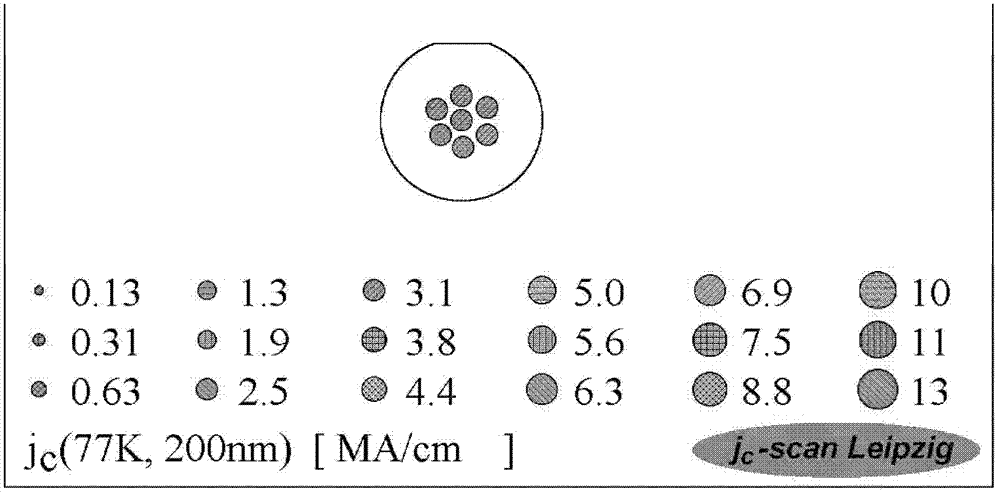

| Property | Measurement | Unit |

|---|---|---|

| Critical current density | aaaaa | aaaaa |

| Critical current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com