Preparation method of high-density ITO (indium tin oxide) evaporation target

A high-density, target material technology, applied in the field of preparation of ITO oxide evaporation materials, can solve the problems of high production cost and risk, achieve the effects of reducing production cost and risk, improving molding ability, and improving product uniformity

Active Publication Date: 2012-10-17

贵州法拉第磁电科技有限公司

View PDF4 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the patent for the preparation of high-density ITO targets, the prepared targets are aimed at sputtering targets for large-scale magnetron sputtering, rather than evaporation targets for GaN and LEDs, and when the targets are sintered By adding high-pressure oxygen to assist combustion, the production cost and risk are relatively high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Login to View More

Abstract

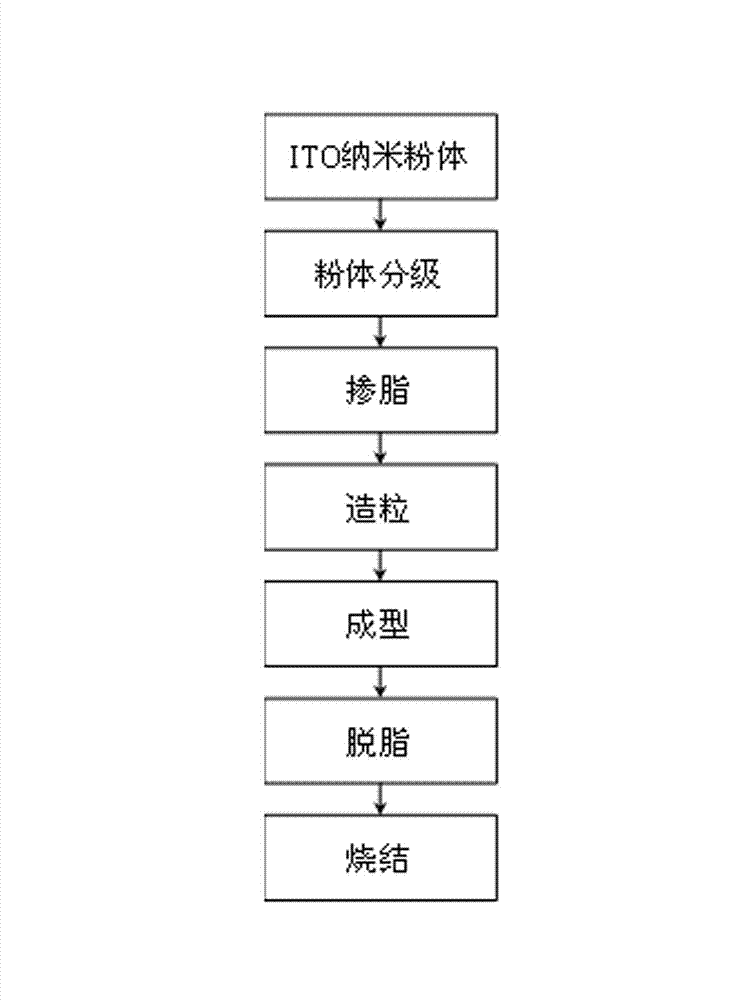

The invention relates to a preparation method of a high-density ITO (indium tin oxide) evaporation target. The method comprises the following process steps: preparing powdery materials, mixing, doping grease, granulating, shaping, degreasing and sintering. By the above steps, the high-density ITO (indium tin oxide) evaporation target is prepared. Through the preparation method provided by the invention, the high-quality high-density ITO (indium tin oxide) evaporation target is beneficial to being sintered in the oxygen atmosphere under the normal pressure or without pressure; a plurality of functional additives are chosen for doping so as to improve the shaping capability and uniformity of the products; the sintering pressure is remarkably reduced, the sintering efficiency is improved and the production cost and the dangerousness are reduced; and, the preparation method provided by the invention is easy to realize continuous and scale production.

Description

technical field [0001] The invention relates to a preparation method of an evaporation coating material, in particular to a preparation method of an ITO oxide evaporation material used for the transparent electrode of a GaN-based light-emitting diode. Background technique [0002] LED (Light Emitting Diode), or light-emitting diode, is a solid-state semiconductor device that can directly convert electrical energy into light energy. LED has changed the principle of traditional incandescent lamp tungsten luminescence and energy-saving lamp sanki toner luminescence, and uses electric field luminescence. LED has the advantages of small size, long life, high luminous efficiency, high brightness, low heat, no radiation, low power consumption, environmental protection and durability. The application fields of LEDs are very wide, and can be roughly divided into five major fields: backlight, lighting, electronic equipment, display screens, and automobiles. Since Nakamura et al. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B35/01C04B35/622

Inventor 周贤界郑子涛许积文陈常青

Owner 贵州法拉第磁电科技有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com