Flexible coiled material for deformation joint and construction method of flexible coiled material

A construction method and deformation joint technology, which are applied in the processing of building materials, construction, and building construction, etc., can solve the problems of broken metal waterstops, increase the construction period, lose the sealing effect, etc., and achieve convenient use and construction. Strong adaptability and stable bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

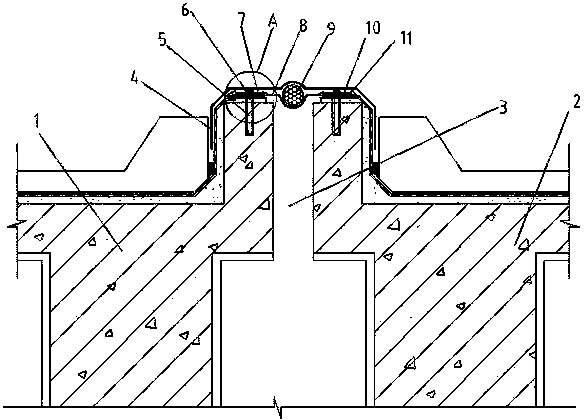

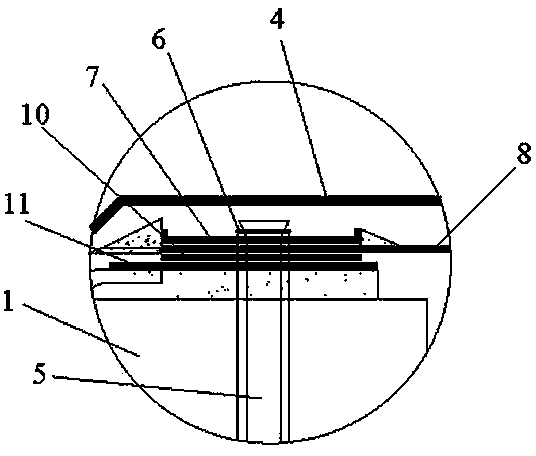

[0035] Below, the specific implementation of the present invention will be described in detail in conjunction with the accompanying drawings.

[0036] For a clearer description of flexible webs and their applications, refer to figure 1 Shown is a structural schematic diagram of sealing deformation joints when the present invention is applied to buildings. Normally, the deformation joint 3 is split from the wall of the building to both sides to form the left wall 1 and the right wall 2, and the middle of the left wall 1 and the right wall 2 is the deformation joint 3. In the present invention, flexible coils are used 8 Cover and seal the deformation joint 3 . Wherein, the flexible roll material 8 has a deformation part and an extension part, the deformation part is located in the middle, has an arc-shaped bend, and a polystyrene foam rod 9 is arranged on the top of the deformation part, and the two sides of the deformation part are connected with extension parts , the flexibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com