Fermentation and refining method for sapindus mukurossi saponin extract

A technology of saponin and refining method, applied in the field of fermentation and refining of plant extracts, can solve the problems of difficult continuous operation of operation units, high product impurity content, poor product stability, etc., and achieves eliminating evaporation or drying units, The effect of stable product quality and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Remove impurities and iron from the air-dried Sapinberry peel (moisture content ≤ 12%). Iron may be mixed in the collection process, which will have a negative impact on the crushing equipment. Use an electric pulverizer to crush the pericarp into fragments of 1 mm or less, add water 5 times its mass, and extract saponin by shaking in a constant temperature shaker at 60°C and 150 rpm for 4 hours. Place the extract in a centrifuge with a rotating speed of 3000rpm, centrifuge for 15min, and collect the supernatant, which is the aqueous extract of Sapindus chinensis. With 10% NaOH solution, add 1-2 drops dropwise to adjust the pH value of the solution to 4.8. Add 10 IU cellobiase to the solution, and carry out saccharification for 96 hours in a full-temperature shaking incubator at 45° C. and 180 rpm.

[0039] 30% NaOH solution was used to adjust the pH value of the solution to 7.0. Divide the solution into 4 parts, numbered 1,2,3,4. Add yeast extract medium to group 1,...

Embodiment 2

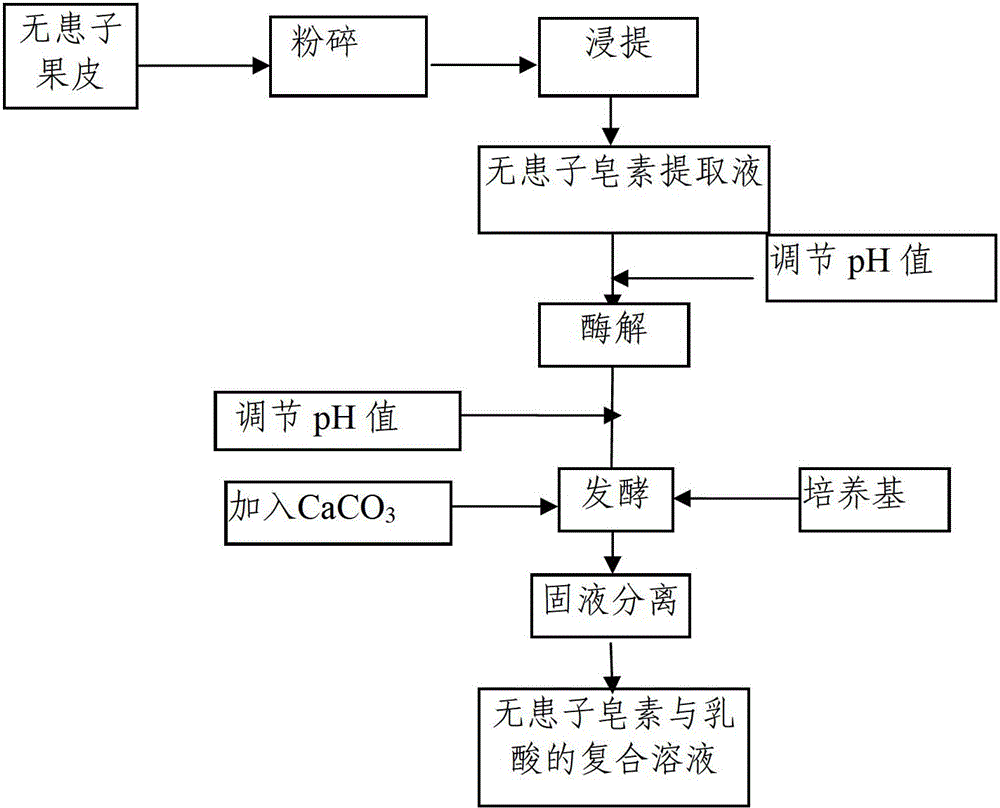

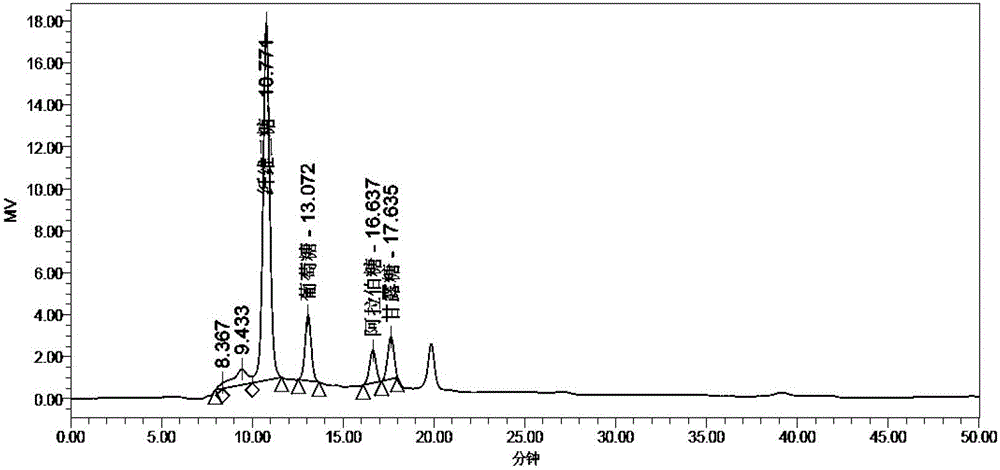

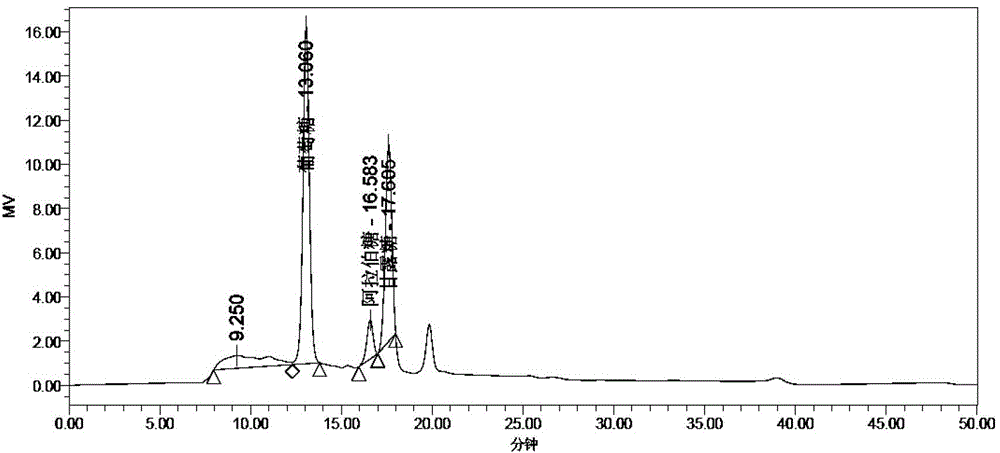

[0043] according to figure 1 The process is to remove impurities and iron from the air-dried sapindus fruit peel, crush the peel with an electric grinder, and crush it into fragments of 1mm or less, add water 7 times its mass, and oscillate in a constant temperature shaker at 50°C and 150 rpm Extract saponin, 5h. Place the extract in a centrifuge with a rotating speed of 3000rpm, centrifuge for 15min, and collect the supernatant, which is the aqueous extract of Sapindus chinensis. The concentration of sugar in the water extract was detected by high performance liquid chromatography ( figure 2 ). The pH of the solution was adjusted to 4.7 with 10% NaOH solution. Add 10 IU cellobiase and 20 IU mannanase to the solution, and carry out saccharification in a shaking incubator at 45° C. and 180 rpm for 96 hours. The sugar concentration in the enzymatic saccharification solution was detected by high performance liquid chromatography ( image 3 ). 30% NaOH solution was used to ...

Embodiment 3

[0046] Remove the impurity and iron from the air-dried Sapindus fruit peel, pulverize the peel with an electric grinder, pass through a 20-mesh sieve, add water 6 times its mass, and extract saponin by shaking in a constant temperature shaker at 70°C and 150 rpm for 2 hours. The extract was placed in a centrifuge with a rotating speed of 3000 rpm, centrifuged for 15 minutes, and the supernatant was collected, which was the aqueous extract of sapindus sapin. The pH of the solution was adjusted to 4.8 with 10% NaOH solution. Add 10 IU cellobiase, 20 IU mannanase and 0.2 mg / ml pectinase to the solution, and carry out saccharification for 80 h in a full-temperature shaking incubator at 50° C. and 180 rpm. 30% NaOH solution to adjust the pH of the solution to 7.5. Add the sterilized yeast extract medium to the enzymolysis solution (in terms of fermentation broth volume, MgSO 4 ·7H 2 O 0.4g / L, KH 2 PO 3 0.4g / L, NaCl0.09g / L, yeast extract 5g / L), lactic acid bacteria 0.4% (mass r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com