Preparation method for high stable phase transition emulsion

A high-stability, emulsion technology, applied in the preparation of microspheres, chemical instruments and methods, microcapsule preparations, etc., to achieve the effect of simple and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Prepare the quality of each component of melamine resin paraffin microcapsule phase-change material emulsion as follows:

[0015]

[0016] The preparation method of melamine resin paraffin microcapsule phase change material emulsion is as follows:

[0017] (1) Add 9.7 g of melamine and 20.1 g of 37% formaldehyde solution into a four-neck flask, dropwise add 0.4 g of triethanolamine, adjust the pH value to 8-9, and stir and react at 70° C. for 30 minutes to prepare a melamine resin prepolymer;

[0018] (2) Prepare an aqueous solution containing 1.0 g of gelatin, add 0.7 g of OP-10 surfactant, heat and stir to prepare an aqueous phase solution;

[0019] (3) Add paraffin to the aqueous phase solution, shear and disperse with a shear emulsifier at a speed of 10,000 rpm for 7 minutes to obtain a paraffin emulsion, and transfer the emulsion and the melamine resin prepolymer to a four-necked flask;

[0020] (4) Connect the condensing reflux water device, add formic acid to...

Embodiment 2

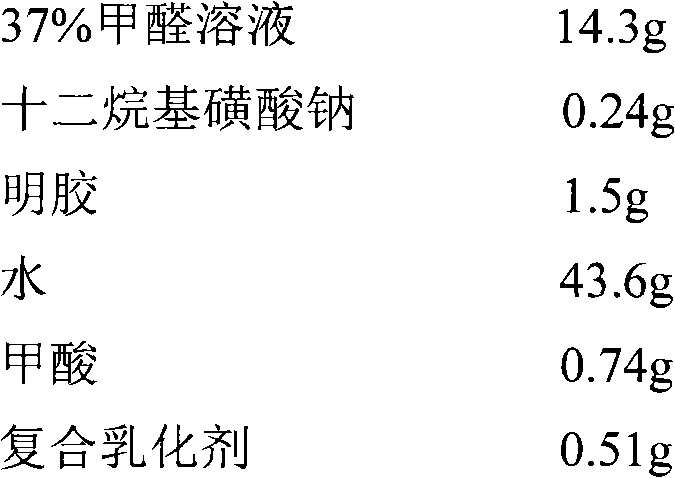

[0024] Prepare the quality of each component of melamine resin paraffin microcapsule phase-change material emulsion as follows:

[0025]

[0026]

[0027] The preparation method of melamine resin paraffin microcapsule phase change material emulsion is as follows:

[0028] (1) Add 7.2 g of melamine and 14.2 g of 37% formaldehyde solution to a four-neck flask, dropwise add triethanolamine, adjust the pH value to 8-9, and stir and react at 70° C. for 30 minutes to prepare a melamine resin prepolymer;

[0029] (2) Prepare an aqueous solution containing 1.5 g of gelatin, add 0.24 g of sodium dodecylsulfonate, heat and stir to prepare an aqueous phase solution;

[0030] (3) Add paraffin to the aqueous phase solution, shear and disperse with a shear emulsifier at a speed of 7500 rpm for 8 minutes to obtain a paraffin emulsion, and transfer the emulsion and the melamine resin prepolymer to a four-necked flask;

[0031] (4) Connect the condensing reflux water device, add formic ...

Embodiment 3

[0035] Prepare the quality of each component of melamine resin paraffin microcapsule phase-change material emulsion as follows:

[0036]

[0037] The preparation method of the sulfur microcapsules that can be used as rubber vulcanizing agent is as follows:

[0038] (1) Add 12.2 g of melamine and 25.4 g of 37% formaldehyde solution into a four-neck flask, dropwise add triethanolamine, adjust the pH value to 8-9, and stir and react at 70° C. for 30 minutes to prepare a melamine resin prepolymer;

[0039] (2) Prepare an aqueous solution containing 1.5g gum arabic, add 0.15g sodium dodecylsulfonate surfactant, heat and stir to prepare an aqueous phase solution;

[0040] (3) Add paraffin to the aqueous phase solution, shear and disperse with a shear emulsifier at a speed of 12,500 rpm for 7 minutes to obtain a paraffin emulsion, and transfer the emulsion and the melamine resin prepolymer to a four-necked flask;

[0041] (4) Connect the condensing reflux water device, add formic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com