Method for extracting algin from fresh Sargassum fusiforme

The technology of hijiki and algin is applied in the field of extraction of algin, which can solve the problems of difficulty in passing through a dyeing filter, poor fluidity, and high calcium content in algin, and achieves safe process operation, expanded raw material range, and better bleaching effect. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

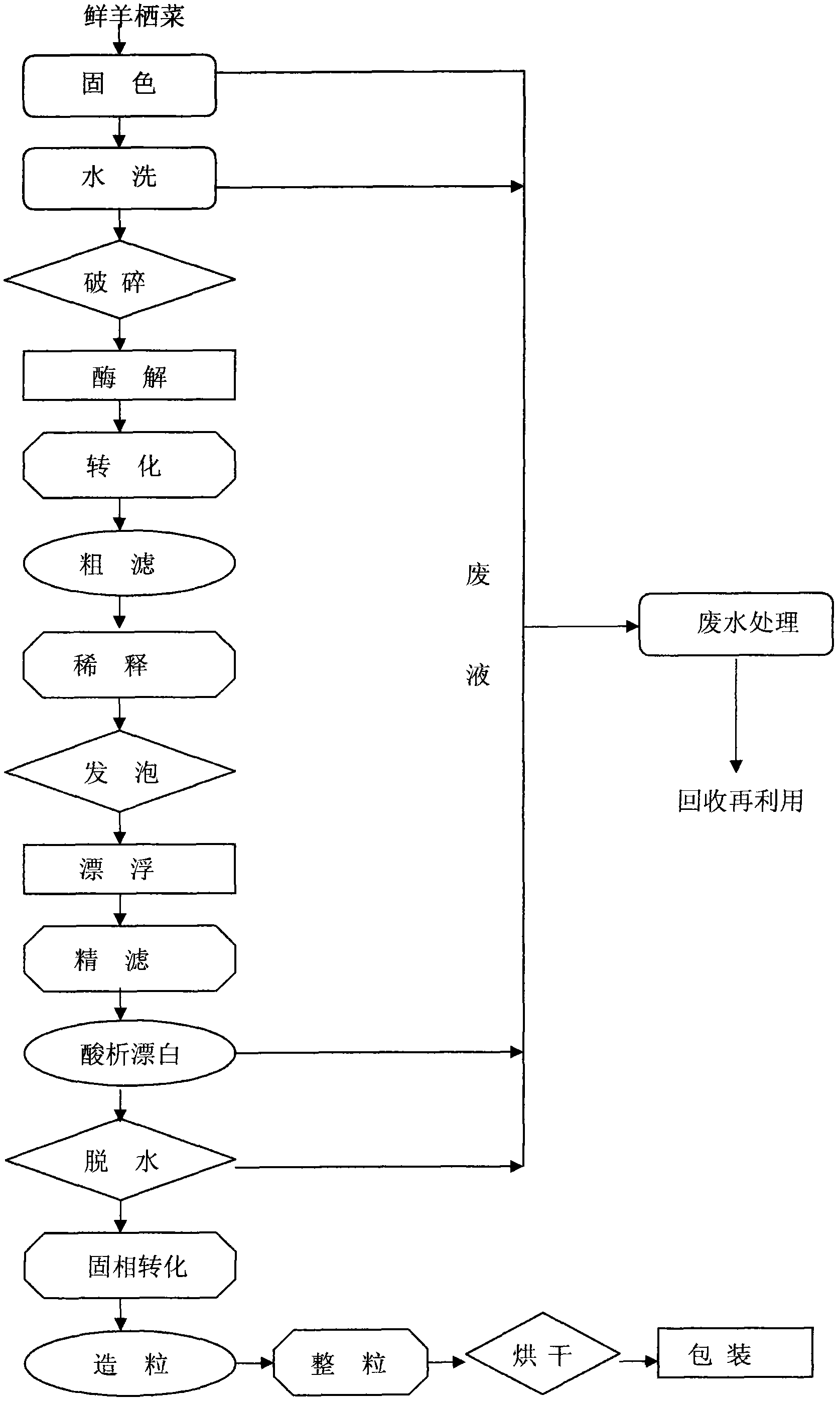

Image

Examples

Embodiment 1

[0071] (1) Color fixation and washing

[0072] Add formaldehyde with a concentration of 40% in the color-fixing pool, the amount of formaldehyde added is 20% of the mass of fresh hijiki, and then add tap water three times the mass of fresh hijiki, and then evenly throw fresh hijiki into the color-fixing pool , after fixing the color for 24 hours, wash with water to remove impurities and excess formaldehyde;

[0073] (2) Broken

[0074] Breaking the washed Hijiki;

[0075] (3) Enzymolysis

[0076] Add 1 mol / L citric acid buffer solution to the crushed fresh hijiki to make the pH of the soaking solution 4.8, use 340 u / g of cellulase, enzymolyze at 55°C for 8 hours, and then raise the temperature to 90°C. Keep at temperature for 30min to inactivate the enzyme;

[0077] (4) Conversion

[0078] Control the temperature of the enzymatically hydrolyzed hijiki at 90°C, make up to 7 times hot water, add soda ash in an amount of 7% of the mass of fresh hijiki, digest for 8 hours, an...

Embodiment 2

[0098] (1) Color fixation and washing

[0099] Add formaldehyde with a concentration of 35% in the color-fixing pool, the amount of formaldehyde added is 10% of the mass of fresh hijiki, and then add tap water twice the mass of fresh hijiki, and then evenly throw fresh hijiki into the color-fixing pool , after fixing the color for 20 hours, wash with water to remove impurities and excess formaldehyde;

[0100] (2) Broken

[0101] Breaking the washed Hijiki;

[0102] (3) Enzymolysis

[0103] Add 1 mol / L citric acid buffer solution to the crushed fresh hijiki to make the pH of the soaking solution 4.8, use 230u / g cellulase, enzymatically hydrolyze at 45°C for 6h, and then raise the temperature to 90°C. Keep at temperature for 20min to inactivate the enzyme;

[0104] (4) Conversion

[0105] Control the temperature of the enzymatically hydrolyzed hijiki at 60°C, make up to 4 times hot water, add soda ash in an amount of 4% of the mass of fresh hijiki, digest for 5 hours, and ...

Embodiment 3

[0125] (1) Color fixation and washing

[0126] Add formaldehyde with a concentration of 38% in the color-fixing pool, the amount of formaldehyde added is 15% of the mass of fresh hijiki, and then add tap water twice the mass of fresh hijiki, and then evenly throw fresh hijiki into the color-fixing pool , after fixing the color for 22 hours, wash with water to remove impurities and excess formaldehyde;

[0127] (2) Broken

[0128] Breaking the washed Hijiki;

[0129] (3) Enzymolysis

[0130] Add 1 mol / L citric acid buffer solution to the crushed fresh hijiki to make the pH of the soaking solution 4.8, use 300 u / g of cellulase, enzymolyze it at 50°C for 7 hours, and then raise the temperature to 90°C. Keep at temperature for 25min to inactivate the enzyme;

[0131] (4) Conversion

[0132] Control the temperature of the enzymatically hydrolyzed hijiki between 70°C, make up to 6 times hot water, add soda ash in an amount of 6% of the mass of fresh hijiki, digest for 7 hours, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com