Modified starch magnetic nano compound and preparation method and application thereof

A nanocomposite and magnetic nanotechnology, which is applied in the direction of alkali metal compounds, chemical instruments and methods, and other chemical processes, can solve the problems of non-reusable, cumbersome cross-linking steps, and time-consuming adsorption of heavy metal ions, etc., and shorten the synthesis cycle , the extraction rate is considerable, the effect of saving manpower and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

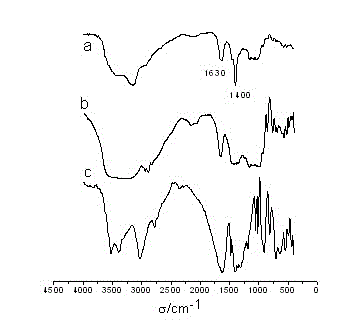

[0030] The modified starch magnetic nanocomposite ES-Fe of the present embodiment 3 o 4 The preparation method of NPs comprises the following steps:

[0031](1) 6.0 g of ethylenediaminetetraacetic acid (EDTA) was dissolved in 60 mL of deionized water, 10 g of potato starch was dissolved in it and completely gelatinized, placed in a microwave reactor and microwaved at 40% output power for 600 s, cooled to room temperature, washed five times with water and absolute ethanol, and dried at 45°C for 8 h to obtain starch derivative ES, which was pulverized for later use;

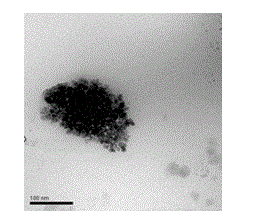

[0032] (2) Dissolve 1.0 g ES in 100 mL N 2 In deionized water after oxygen removal, heat up to 80 °C, stir for 25 min, then dissolve 5.8 g of ferric nitrate and 2.3 g of ferrous sulfate in the solution, and add 10 mL of 26% by mass concentration of Ammonia water was reacted for 1 h under the protection of nitrogen, magnetically separated after standing, washed with deionized water until neutral, and the magneti...

Embodiment 2

[0049] The modified starch magnetic nanocomposite ES-Fe of the present embodiment 3 o 4 The preparation method of NPs comprises the following steps:

[0050] (1) Dissolve 2.0 g of ethylenediaminetetraacetic acid (EDTA) in 50 mL of deionized water, dissolve 5 g of potato starch in it and completely gelatinize it, place it in a microwave reactor and heat it with microwave at 40% output power for 300 s, cooled to room temperature, washed five times with water and absolute ethanol, and dried at 45°C for 6 h to obtain starch derivative ES, which was pulverized for later use;

[0051] (2) Dissolve 1.0 g ES in 100 mL N 2 In deionized water after oxygen removal, heat up to 80 °C, stir for 30 min, then dissolve 5.8 g of ferric nitrate and 2.3 g of ferrous sulfate in the solution, and add 10 mL of 26% ferrous sulfate under stirring at 1500 rpm Ammonia water was reacted for 4 h under the protection of nitrogen, magnetically separated after standing, and washed with deionized water un...

Embodiment 3

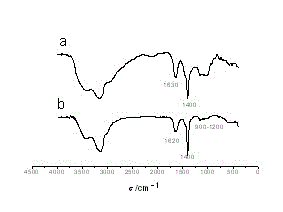

[0061] The modified starch magnetic nanocomposite ES-Fe of the present embodiment 3 o 4 The preparation method of NPs comprises the following steps:

[0062] (1) Dissolve 8.0 g of ethylenediaminetetraacetic acid (EDTA) in 100 mL of deionized water, dissolve 15 g of potato starch in it and completely gelatinize it, place it in a microwave reactor and heat it with microwave at 40% output power for 800 s, cooled to room temperature, washed 5 times with water and absolute ethanol respectively, and dried at 45 °C for 10 h to obtain starch derivative ES, which was pulverized for later use;

[0063] (2) Dissolve 1.0 g ES in 100 mL N 2 In deionized water after oxygen removal, heat up to 80 °C, stir for 35 min, then dissolve 5.8 g of ferric nitrate and 2.3 g of ferrous sulfate in the solution, and add 10 mL of 26% by mass concentration of Ammonia water was reacted for 2 h under the protection of nitrogen, magnetically separated after standing, washed with deionized water until neut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com