Purifying system for multi-phase photocatalysis treatment of waste gases

A waste gas purification system and purification system technology, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, to achieve the effects of expanding the scope of application, benefiting environmental protection, and improving the purification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

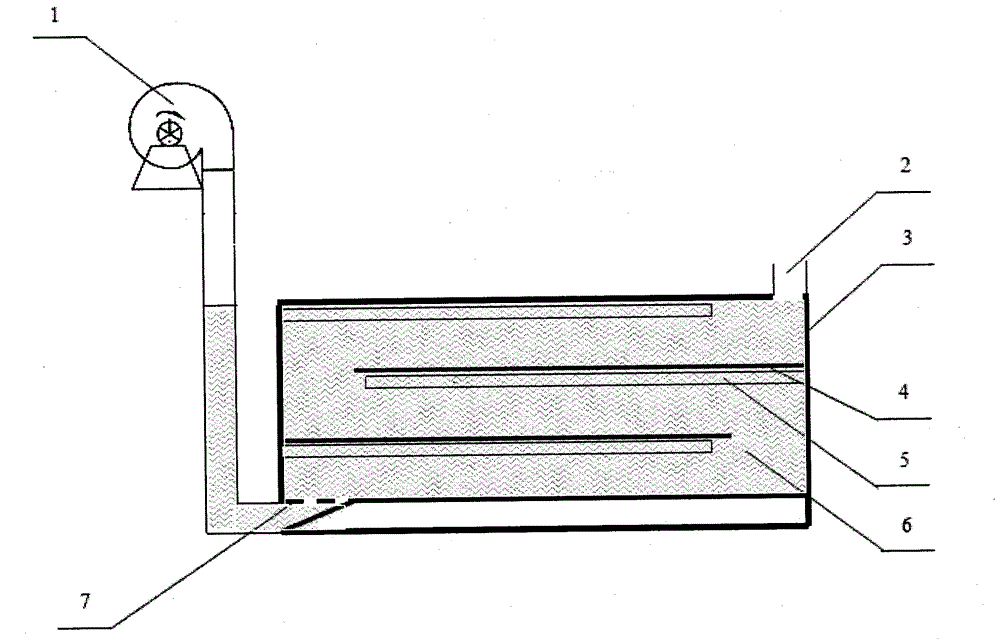

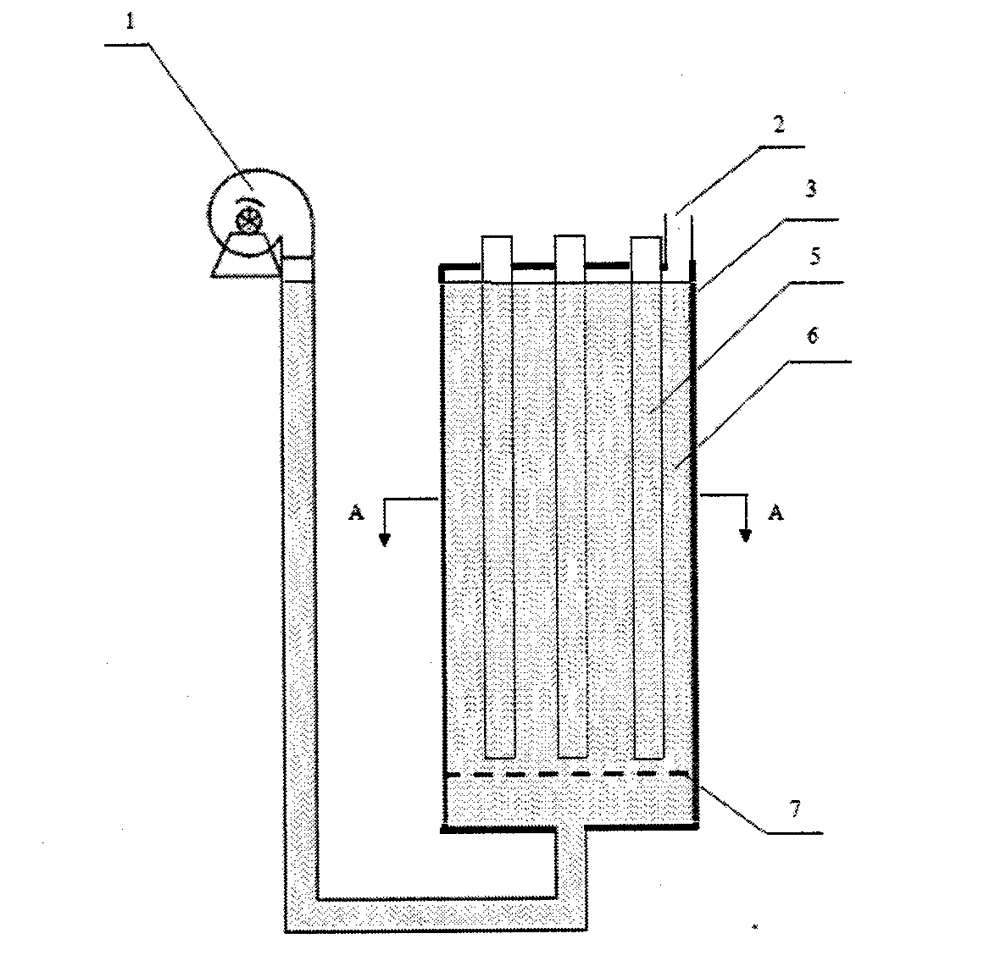

[0031] Such as figure 1 As shown, a purification system for heterogeneous photocatalytic treatment of waste gas is a filling type waste gas treatment and purification system. The filling type multiphase photocatalytic treatment of waste gas purification system mainly includes a blower 1, an exhaust port 2, and a reaction chamber 3. Ultraviolet lamp tube 5, nano-titanium dioxide suspension 6, exhaust gas diffuser 7, etc.

[0032] The blower 1 is a commercially available component, the outlet of the blower 1 communicates with the gas inlet at the bottom of the reaction chamber 3, and the waste gas to be treated passes through the blower 1 and the connecting pipe, and flows from the air inlet After passing through the exhaust gas disperser 7 and dispersing, it enters the reaction chamber 3 for treatment and purification.

[0033] The material of the reaction chamber 3 is stainless steel, and the shape of the reaction chamber 3 is rectangular. The rectangular reaction chamber 3 ...

Embodiment 2

[0037] A purification system for heterogeneous photocatalytic treatment of waste gas, same as Example 1, wherein:

[0038] The rectangular reaction chamber 3 has a length of 1000 mm, a width of 440 mm, a height of 600 mm, and a wall thickness of 1 mm. At the bottom of the rectangular reaction chamber 3 located on the side of the blower 1, a circular through hole (namely an air inlet) with a diameter of 60 mm is provided. In the rectangular reaction chamber 3, perpendicular to the upper side of the air inlet, the gas-guiding baffles 4 with a pitch of 100 mm are fixed horizontally and staggeredly, and the length of each air-guiding baffle 4 is 700mm, the width is matched with the width of the rectangular reaction chamber 3, the thickness is 1mm, and the material is a stainless steel plate. The lower surface of 4 is respectively fixed with the above-mentioned array of ultraviolet lamp tubes 5 parallel to each other with a distance of 50mm, and the power of each ultraviolet lamp ...

Embodiment 3

[0042] A purification system for heterogeneous photocatalytic treatment of waste gas, same as Example 1, wherein:

[0043] The rectangular reaction chamber 3 has a length of 2000mm, a width of 1800mm, a height of 2000mm, and a wall thickness of 3mm. At the bottom of the rectangular reaction chamber 3 on one side of the blower 1, a circular through hole (ie, an air inlet) with a diameter of 250 mm is provided. In the rectangular reaction chamber 3, perpendicular to the top of the air inlet, the air guide baffles 4 with a spacing of 300 mm are fixed horizontally and staggeredly, and the length of each air guide baffle 4 is It is 1850mm, the width matches the width of the inner chamber of the rectangular reaction chamber 3, the thickness is 3mm, and the material is a stainless steel plate. The lower surface of 4 is respectively fixed with the above-mentioned array of ultraviolet lamp tubes 5 parallel to each other with a distance of 100mm, and the power of each ultraviolet lamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com