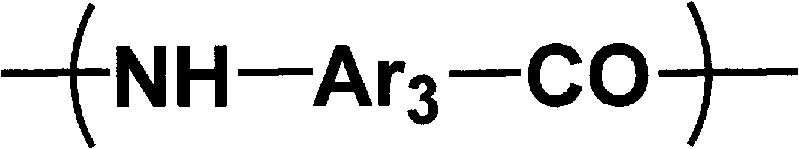

Aromatic polyamide porous film and separator for capacitor or battery using same

An aromatic polyamide, porous membrane technology, used in hybrid capacitor separators, capacitors, electrolytic capacitors, etc., can solve the problems of reduced membrane strength, weakened hydrophilicity, and no improvement of pore surface, and achieves sufficient heat resistance. Good effect of sex and affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0154] In dehydrated N-methyl-2-pyrrolidone (NMP), dissolve 2-chloro-p-phenylenediamine corresponding to 80 mol% of the total amount of diamines and 4,4 '-Diaminodiphenyl ether, and then add 2-chloroterephthaloyl chloride (CTPC) equivalent to 98.5 mol% of the total amount of diamine, and polymerize after stirring for 2 hours to obtain a solution of aromatic polyamide . The solution temperature at the start of the polymerization was 4°C. CTPC was divided into 10 equal portions and added at intervals of 10 minutes, thereby controlling the temperature increase during the polymerization to 28°C or less. This solution was put into a mixer together with water, and the polymer was precipitated while stirring, and taken out. The polymer taken out was washed with water, fully dried and dissolved in NMP, and 100 parts by mass of polyvinylpyrrolidone (PVP) with a weight average molecular weight of 1 million was added to 100 parts by mass of aromatic polyamide to obtain a polymer concent...

Embodiment 2

[0156] A porous membrane was obtained in the same manner as in Example 1 except that the hydrophilic polymer was PVP having a weight average molecular weight of 500,000. Table 2 shows the evaluation results of the obtained porous membrane.

Embodiment 3

[0158] A porous membrane was obtained in the same manner as in Example 1, except that the amount of the hydrophilic polymer added to the membrane-forming stock solution was 50 parts by mass and the polymer concentration of the film-forming stock solution was 12% by mass. Table 2 shows the evaluation results of the obtained porous membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com