Manufacture method of metal-multilayer insulator-metal capacitor

A multi-layer insulator and metal capacitor technology, applied in the field of microelectronics, can solve the problems of large leakage current of silicon nitride film capacitors, and achieve the effects of improving electrical uniformity, breakdown voltage and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in combination with principle diagrams and specific operation examples.

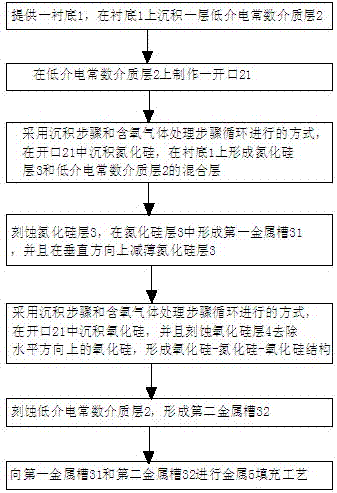

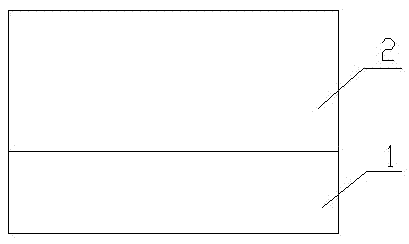

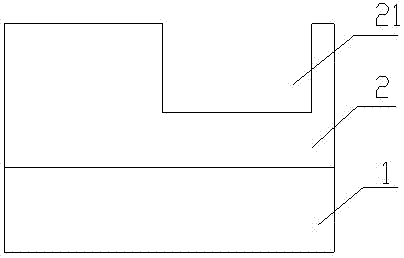

[0029] Such as figure 1 And shown in Fig. 2A-2F, a kind of fabrication method of metal-multilayer insulator-metal capacitor of the present invention specifically comprises the following steps:

[0030] Step S1: providing a substrate 1, and depositing a layer of low dielectric constant (low K value) dielectric layer 2 on the substrate 1;

[0031] Step S2: making an opening 21 on the low dielectric constant dielectric layer 2;

[0032] Step S3: Deposit silicon nitride in the opening 21. In this step, the deposition of silicon nitride is carried out by using a plasma-enhanced chemical vapor deposition method and an oxygen-containing gas treatment method in a cycle, that is, firstly, using plasma Silicon nitride is deposited by volume-enhanced chemical vapor deposition, then treated with oxygen-containing gas, and then silicon nitride is depo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com