Multilayer varistor and preparation method for same

A technology of varistors and varistors, applied in the direction of varistor cores, varistors, resistors, etc., can solve the problems of high voltage gradient, poor resistance to current impact, high production cost, etc., to improve the overall Performance, Guaranteed Consistency, Low Cost of Production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

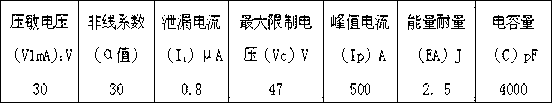

Embodiment 1

[0014] A multilayer varistor, comprising a varistor body, and an internal electrode in a porcelain body, the varistor body is made of ZnO-Bi 2 o 3 - SiO 2 -SnO 2 It is composed of a ceramic material system, and the internal electrode is a pure Ag electrode. The ZnO-Bi 2 o 3 -SiO 2 -SnO 2 It is a ceramic material system, and its specific molar formula components are: ZnO 91.0mol%, Bi 2 o 3 2.0 mol%, SiO 2 1.0mol%, SnO 2 1.0mol%, Sb 2 o 3 1.2mol%, TiO 2 1.5mol%, Co 3 o 4 1.0mol%, MnCO 3 0.7mol%, Cr 2 o 3 0.5mol%, Nd 2 o 3 0.05mol%, Al(NO 3 ) 3 .9H 2 O 0.006mol%. Its preparation method includes batching, batching ball milling, casting, molding, drying, lamination, cutting, debinding, sintering, chamfering, capping, firing, electroplating, testing, finished product inspection, taping / packaging, and storage procedures , the described ingredient ball milling is to first make the Bi in the formula 2 o 3 , SiO 2 , SnO 2 , Sb 2 o 3 、TiO 2 、Co 3 o...

Embodiment 2

[0018]The ceramic material and component process are the same as in Example 1, and the product specification is 0805 product, in which the thickness of the dielectric layer is designed to be 50 μm, the number of layers is 5 layers, and the sintering temperature is 880°C / 5h.

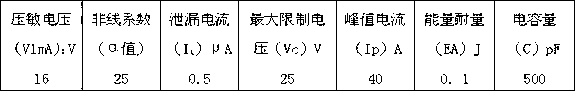

[0019] The electrical performance parameters of the product are good, as shown in Table 2:

[0020] Table 2

[0021]

Embodiment 3

[0023] The ceramic material and component process are the same as in Example 1, and the product specification is 1812 products, in which the thickness of the dielectric layer is designed to be 100 μm, the number of layers is 10, and the sintering temperature is 880°C / 5h.

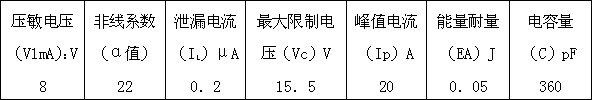

[0024] The electrical performance parameters of the product are good, as shown in Table 3:

[0025] table 3

[0026]

[0027] It can be seen from Tables 1-3 that the pressure sensitive device prepared by the present invention has good main electrical parameters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com