Zirconium nano composite functional tencel fabric and weaving, dyeing and finishing process and application thereof

A nano-composite and fabric technology, which is applied in the fields of application, rayon manufacturing, textiles and papermaking, etc., can solve the problems of inability to guarantee the adhesion and stability of nano-powder, complicated process and equipment requirements, technical difficulties, etc., and achieve good absorption near Infrared characteristics, excellent high-efficiency functional characteristics, good anti-ultraviolet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

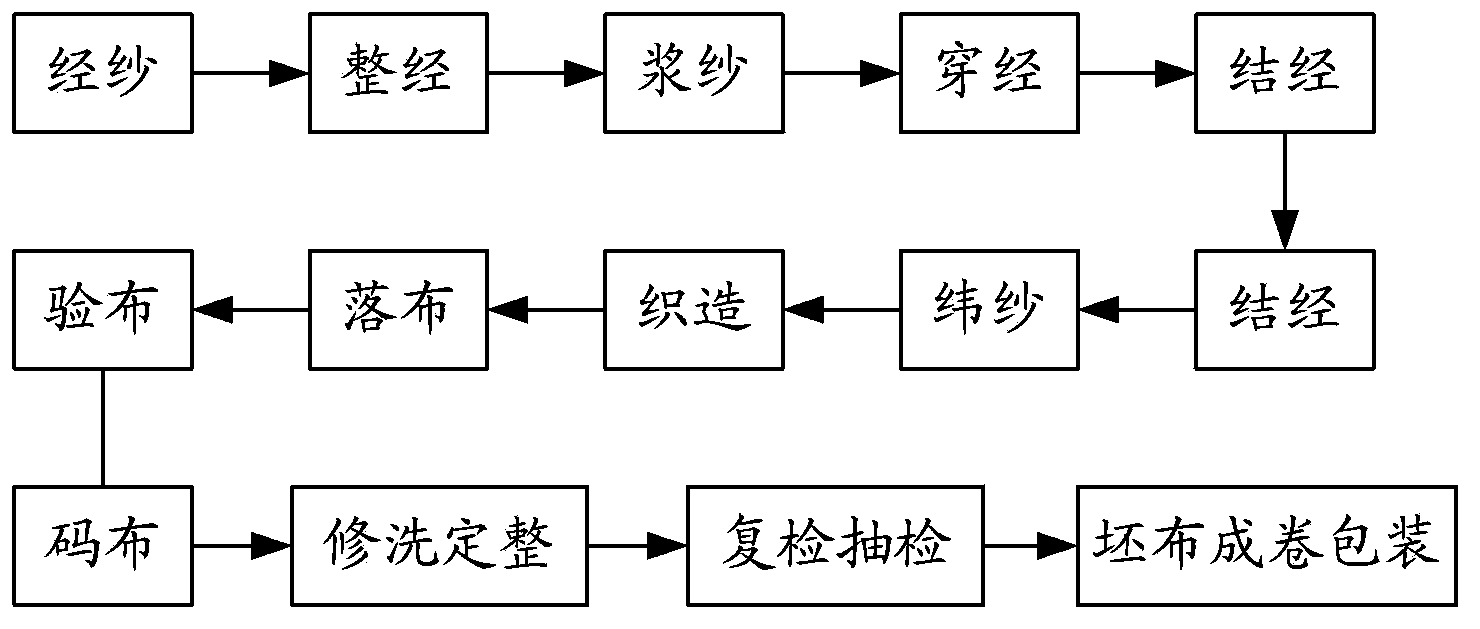

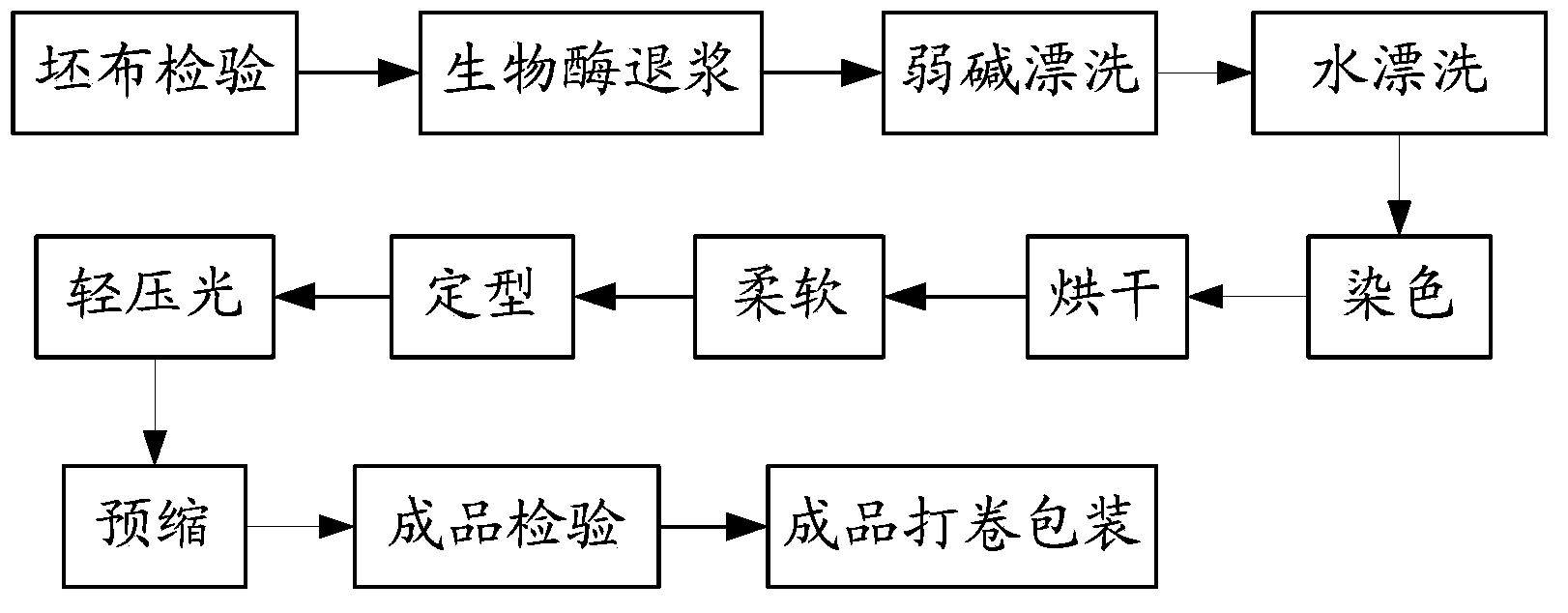

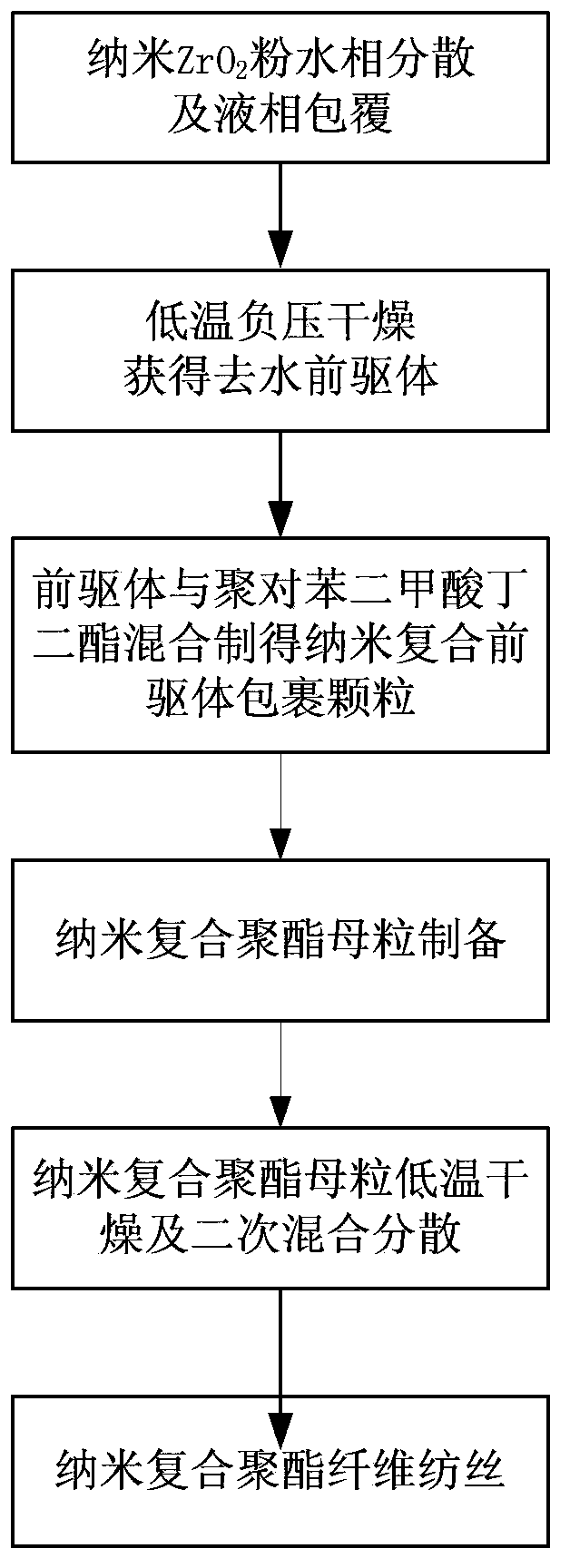

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, the zirconium nanocomposite functional tencel fabric is composed of zirconium nanofunctional fibers and Tencel The fibers are interwoven, and the zirconium nanocomposite polyester fiber is used as the weft weave of the fabric. Tencel The fiber is used as the warp structure of the fabric, and the content of zirconium nano-functional fibers in the fabric is 40wt%. Tencel The fiber content is 60wt%; the zirconium nano functional fiber contains the following raw material components: nano zirconium dioxide (particle size: 10-60nm) powder: 1.8 parts by weight; polybutylene terephthalate: 3.2 parts by weight; Ethylene diformate: 95 parts by weight; auxiliary agent: trace amount, the auxiliary agent includes the reaction product of ethyl oleate sulfonate potassium and rosin amine, and ethylene-acrylic acid copolymerized wax. The additive content is 10% of the weight of nano zirconia powder. The monofilament fineness of zirconium nanocomposite polyester ...

Embodiment 2

[0042] In this embodiment, the zirconium nanocomposite functional tencel fabric is composed of zirconium nanofunctional fibers and Tencel The fibers are interwoven, and the zirconium nanocomposite polyester fiber is used as the weft weave of the fabric. Tencel The fiber is used as the warp structure of the fabric, and the content of zirconium nano-functional fiber in the fabric is 35wt%. Tencel The fiber content is 65wt%; zirconium nano functional fibers contain the following raw material components: nano zirconium dioxide powder (particle size: 10-60nm): 1.7 parts by weight; polybutylene terephthalate: 2.3 parts by weight; Ethylene diformate: 96 parts by weight; auxiliary agent: trace amount, the auxiliary agent includes the reaction product of ethyl oleate sulfonate potassium and rosin amine, and ethylene-acrylic acid copolymerized wax. The additive content is 5% of the weight of the nano zirconia powder. The monofilament fineness of zirconium nanocomposite polyester fi...

Embodiment 3

[0045] In this embodiment, the zirconium nanocomposite functional tencel fabric is composed of zirconium nanofunctional fibers and Tencel The fibers are interwoven, and the zirconium nanocomposite polyester fiber is used as the weft weave of the fabric. Tencel The fiber is used as the warp structure of the fabric, and the content of zirconium nano-functional fibers in the fabric is 45wt%. Tencel The fiber content is 55wt%; the zirconium nano functional fiber contains the following raw material components: nano zirconium dioxide powder (particle size: 10-60nm): 1.6 parts by weight; polybutylene terephthalate: 2.4 parts by weight; Ethylene diformate: 96 parts by weight; auxiliary agent: trace amount, the auxiliary agent includes the reaction product of ethyl oleate sulfonate potassium and rosin amine, and ethylene-acrylic acid copolymerized wax. The additive content is 10% of the weight of nano zirconia powder. The monofilament fineness of zirconium nanocomposite polyester ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com