Zirconium base blocky amorphous/nanocrystalline alloy with antibacterial action and preparation method thereof

A nanocrystalline alloy, antibacterial technology, applied in the field of zirconium-based bulk amorphous/nanocrystalline alloy and its preparation, can solve the problem of high probability of bacterial infection, achieve good mechanical biocompatibility, good antibacterial or bacteriostatic, The effect of high yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

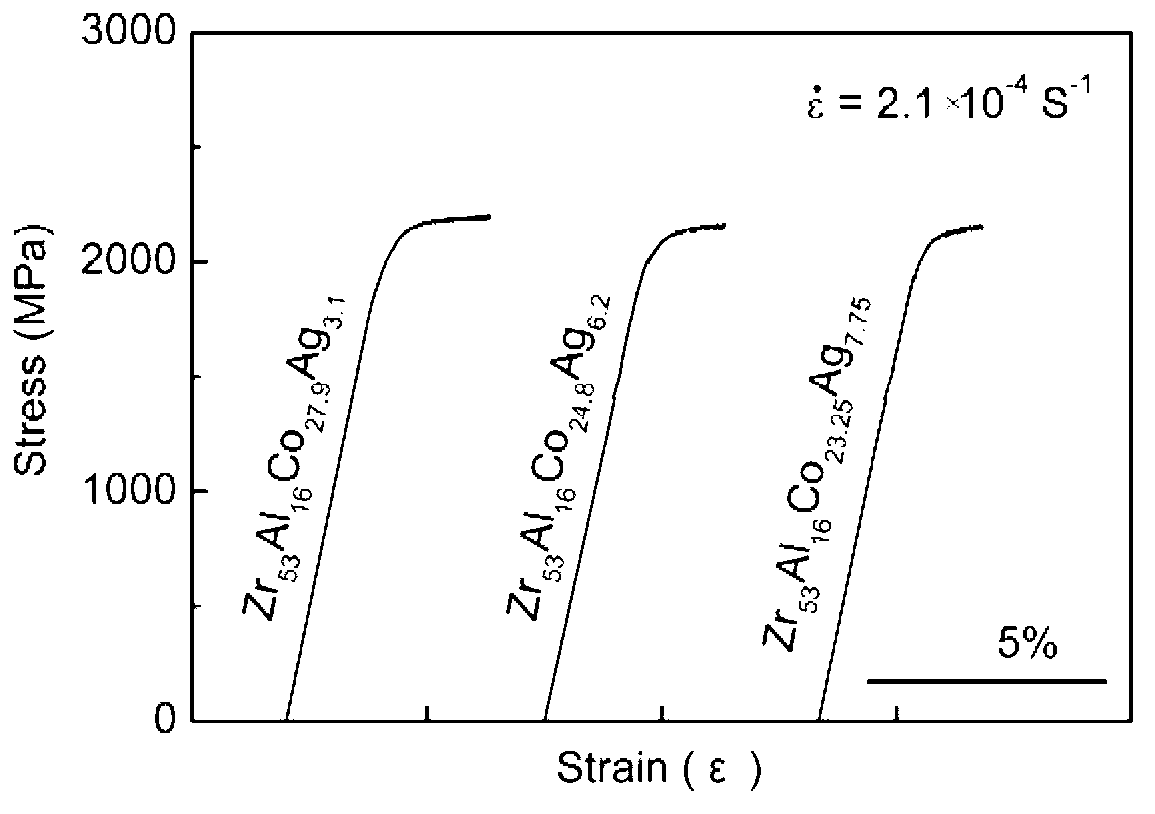

[0048] Zr with a diameter of 8 mm was prepared by copper mold casting 53 al 16C o 27.9 Ag 3.1 bulk amorphous alloy

[0049] Step 1: Ingredients

[0050] Press Zr 53 al 16 co 27.9 Ag 3.1 The nominal composition weighs raw materials;

[0051] Among them, the mass percentage purity of zirconium (Zr) is 99.8%; the mass percentage purity of cobalt (Co) is 99.98%; the mass percentage purity of aluminum (Al) is 99.9%; the mass percentage purity of silver (Ag) is 99.9%.

[0052] Step 2: Smelting Zr 53 al 16 co 27.9 Ag 3.1 Master Alloy

[0053] The raw material weighed in step 1 is put into a vacuum electric arc furnace;

[0054] Adjust the vacuum degree of the vacuum chamber of the vacuum electric arc furnace to 5×10 -3 Pa, and then filled with high-purity (99.999%) argon to make the vacuum of the vacuum chamber to 0.5×10 5 Pa;

[0055] After arc melting for 240s, the arc is broken to form the first alloy ingot;

[0056] Flip the first alloy ingot, and after arc melt...

Embodiment 2

[0070] Zr with a diameter of 16 mm was prepared by copper mold casting 53 al 16 co 24.8 Ag 6.2 bulk amorphous alloy

[0071] Step 1: Ingredients

[0072] Press Zr 53 al 16 co 24.8 Ag 6.2 The nominal composition weighs raw materials;

[0073] Among them, the mass percentage purity of zirconium (Zr) is 99.8%; the mass percentage purity of cobalt (Co) is 99.98%; the mass percentage purity of aluminum (Al) is 99.9%; the mass percentage purity of silver (Ag) is 99.9%.

[0074] Step 2: Smelting Zr 53 al 16 co 24.8 Ag 6.2 Master Alloy

[0075] The raw material weighed in step 1 is put into a vacuum electric arc furnace;

[0076] Adjust the vacuum degree of the vacuum chamber of the vacuum electric arc furnace to 3×10 -3 Pa, and then filled with high-purity (99.999%) argon to make the vacuum of the vacuum chamber to 0.8×10 5 Pa;

[0077] After arc melting for 300s, the arc is broken to form the first alloy ingot;

[0078] Flip the first alloy ingot, after arc melting...

Embodiment 3

[0092] Zr with a diameter of 20 mm was prepared by copper mold casting 53 Al 16 co 23.25 Ag 7.75 bulk amorphous alloy

[0093] Step 1: Ingredients

[0094] Press Zr 53 Al 16 co 23.25 Ag 7.75 The nominal composition weighs raw materials;

[0095] Among them, the mass percentage purity of zirconium (Zr) is 99.8%; the mass percentage purity of cobalt (Co) is 99.98%; the mass percentage purity of aluminum (Al) is 99.9%; the mass percentage purity of silver (Ag) is 99.9%.

[0096] Step 2: Smelting Zr 53 Al 16 co 23.25 Ag 7.75 Master Alloy

[0097] The raw material weighed in step 1 is put into a vacuum electric arc furnace;

[0098] Adjust the vacuum degree of the vacuum chamber of the vacuum electric arc furnace to 4×10 -3 Pa, and then filled with high-purity (99.999%) argon to make the vacuum of the vacuum chamber to 0.5×10 5 Pa;

[0099] After arc melting for 300s, the arc is broken to form the first alloy ingot;

[0100] Flip the first alloy ingot, and after a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Crystallization temperature | aaaaa | aaaaa |

| Liquidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com