Preparation method of nano cuprous oxide@copper oxide/stone needle fiber as well as product and application thereof

A nano-cuprous oxide and Bianstone technology, which is applied in the field of fiber manufacturing, can solve the problems that towels are easy to breed bacteria, the antibacterial lasting rate is not high, and the skin can not play a good protective effect, so as to help sleep and prevent antibacterial well. Antibacterial and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

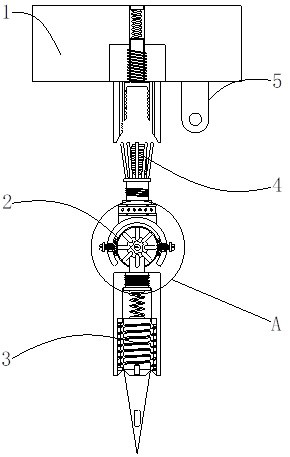

Image

Examples

Embodiment 1

[0059] Dissolve Bianstone powder and soluble copper acetate in deionized water at a mass ratio of 4:1 and ultrasonically disperse for 60 minutes, which is marked as suspension A; add 4M sodium hydroxide to the above solution A, and magnetically stir until uniform for 30 minutes, which is marked as suspension B ;Add weak reducing agent glucose to the above suspension, the molar ratio of glucose to soluble copper acetate is 1:2, centrifuge after magnetic stirring for 60min, and wash several times with deionized water and ethanol to obtain product C; disperse product C In 100mL of 15% hydrogen peroxide, magnetically stirred for 6h, then centrifuged and dried at 60°C for 1h to obtain nano-cuprous oxide @ copper oxide / meteorite. Dissolve 30 parts by weight of nano-cuprous oxide @ copper oxide / meteorite and 25 parts by weight of chitosan in 55 parts by weight of polar solution acetic acid, wherein the degree of deacetylation of chitosan is 80%, stir magnetically at room temperatu...

Embodiment 2

[0064] Dissolve Bianstone powder and soluble copper citrate in deionized water at a mass ratio of 4:1 and ultrasonically disperse for 30 minutes, and mark it as suspension A; add 6M potassium hydroxide to the above solution A, stir it until uniform by magnetic force for 30 minutes, mark it as suspension B: Add sodium borohydride, a weak reducing agent, to the above suspension, the molar ratio of sodium borohydride to soluble copper citrate is 1:2, centrifuge after magnetic stirring for 60 minutes, and wash with deionized water and ethanol several times to obtain the product C: The product C was dispersed in 100 mL of 15% hydrogen peroxide, magnetically stirred for 6 hours, then centrifuged and dried at 60°C for 1 hour to obtain nano-cuprous oxide@copper oxide / stone meteorite. Dissolve 35 parts by weight of nano-cuprous oxide@copper oxide / bian stone and 35 parts by weight of chitosan in 45 parts by weight of polar solution acetic acid. The degree of deacetylation of chitosan is ...

Embodiment 3

[0069] Dissolve Bianstone powder and soluble copper lactate in deionized water at a mass ratio of 4:1 and ultrasonically disperse for 30 minutes, which is marked as suspension A; add 6M potassium hydroxide to the above solution A, and magnetically stir until uniform for 30 minutes, which is marked as suspension B Add weak reducing agent glucose to the above suspension, the molar ratio of glucose to soluble copper citrate is 1:2, centrifuge after magnetic stirring for 60min, and wash several times with deionized water and ethanol to obtain product C; Disperse in 100mL of hydrogen peroxide with a mass fraction of 15%, magnetically stir for 6h, then centrifuge and dry at 80°C for 1h to obtain the final product nano-cuprous oxide @ copper oxide / meteorite. Dissolve 35 parts by weight of nano-cuprous oxide@copper oxide / bian stone and 25 parts by weight of chitosan in 55 parts by weight of polar solution acetic acid. The degree of deacetylation of chitosan is 100%. Stir magnetically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com