Ultraviolet curing anticorrosive coating

A technology of anti-corrosion coatings and ultraviolet light, which is applied in the direction of anti-corrosion coatings and coatings, and can solve problems affecting the health of operators, stimulation, and viscosity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] Correspondingly, the preparation method of the UV-curable anticorrosion coating comprises the following steps: mixing and stirring 16-30 parts by weight of water-based UV-curable oligomer and 0.3-5 parts by weight of water-based polyaniline, adding 20-38 parts by weight of The pigment, 6-21 parts by weight of filler, and 0.5-7 parts by weight of photoinitiator are sand-milled to obtain an ultraviolet-curable anticorrosion coating.

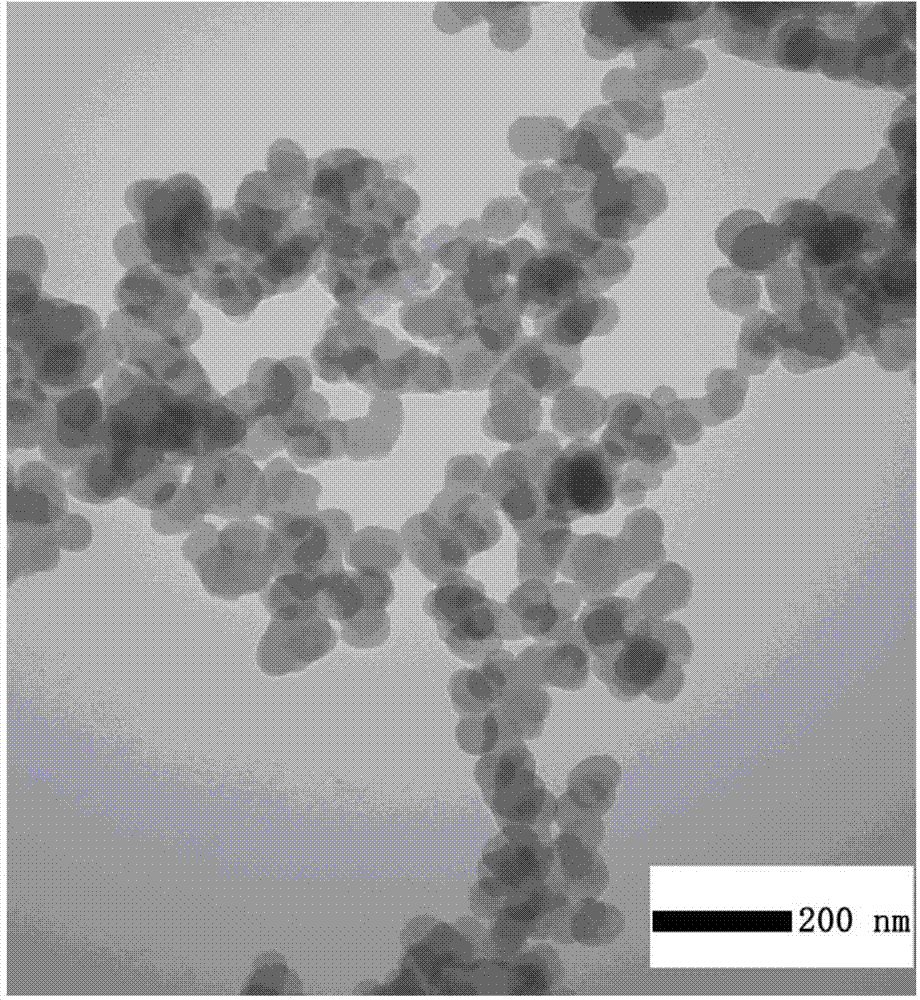

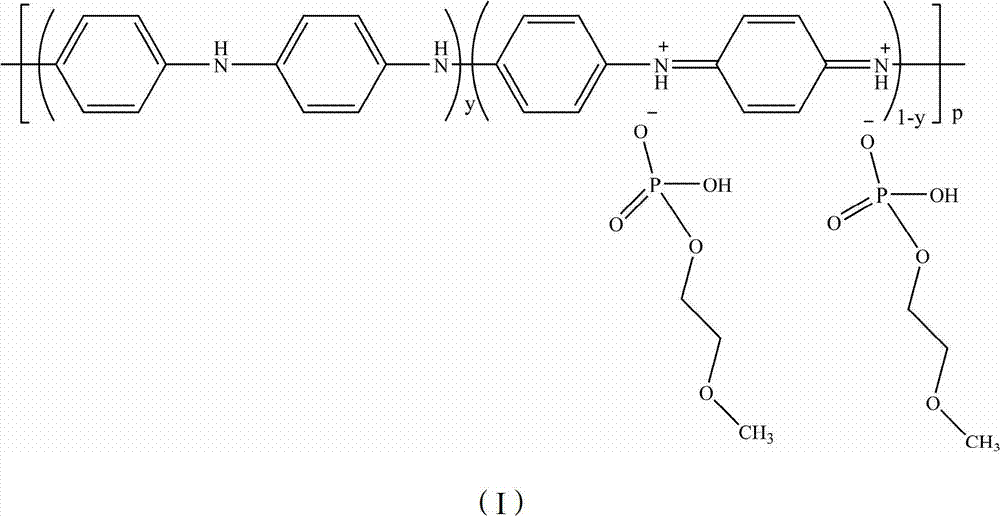

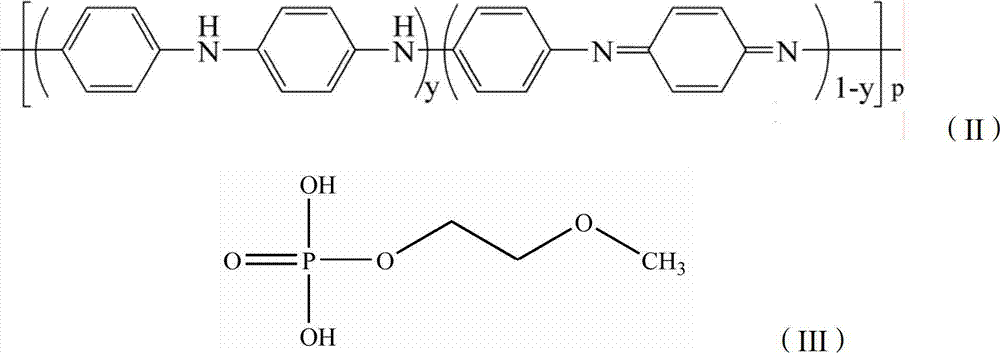

[0064] Among them, the water-based UV-curable oligomer has unsaturated bonds to form a dense coating after UV-curing, and the oxidation-reduction potential of the phosphate-doped water-based polyaniline is 0.5~0.7V vs. SCE is higher than the intrinsic state The oxidation-reduction potential of polyaniline makes it easier to oxidize the surface of steel to form a dense metal oxide film.

[0065] According to the present invention, the preparation method of the UV-curable anticorrosion coating preferably also adds 2 to 8 parts by weight of wat...

Embodiment 1

[0072] The preparation of embodiment 1 waterborne polyurethane acrylate oligomer

[0073] 1.1 Under the protection of dry nitrogen, add 200g of polybutylene adipate with a molecular weight of 2kDa and 100g of polypropylene glycol with a molecular weight of 1kDa after vacuum dehydration into a three-necked flask, and raise the temperature to 85°C. 226.2 g of 2,4-toluene diisocyanate was added dropwise at a high speed, and after the dropwise addition was completed, the reaction was continued for 2 hours to obtain the first intermediate product.

[0074] 1.2 After cooling the first intermediate product obtained in 1.1 to 70°C, add 150ml butanone, 40.2g 2,2-dimethylolpropionic acid and 0.0001g dibutyltin dilaurate, and react for 1.5h to obtain the second intermediate product.

[0075] 1.3 Warm up the second intermediate product obtained in 1.2 to 65°C, add 178.9g of pentaerythritol triacrylate, react for 2 hours, add 200ml of deionized water to emulsify for 20min, add 24.2g of tr...

Embodiment 2

[0076] The preparation of embodiment 2 waterborne epoxy acrylate oligomers

[0077] 2.1 Under the protection of nitrogen, slowly heat 120g of bisphenol A epoxy resin E44 and 0.06g of hydroquinone to 70°C, add a mixture of 76.1g of acrylic acid and 0.93g of triethylamine dropwise at a rate of 6ml / min, and then heat up To 90°C, react for 2.5h to obtain epoxy acrylate oligomer.

[0078] 2.2 Cool down the epoxy acrylate oligomer obtained in 2.1 to 70°C, add 0.02g of hydroquinone, 0.23g of tetrabutylammonium bromide and 103.5g of maleic anhydride, heat to 75°C, and react 2h, lower the temperature to 40°C, add 130g of deionized water under the condition of stirring at a rotating speed of 800rpm / min, stir for 20min, then add 86g of triethylamine, and continue stirring for 30min to obtain a water-based epoxy acrylate oligomer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com