Treatment method for molybdenum-containing acid wastewater generated in production of ammonium molybdate

A production process, acid wastewater technology, applied in the direction of neutralization water/sewage treatment, heating water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the impact of molybdenum production cost and comprehensive recovery rate, chemical hazards, treatment Low efficiency and other problems, to achieve the effect of simple equipment process and operation method, improved comprehensive recovery rate, and easy control of parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A treatment method for molybdenum-containing acidic waste water produced in the ammonium molybdate production process, the concrete steps are as follows:

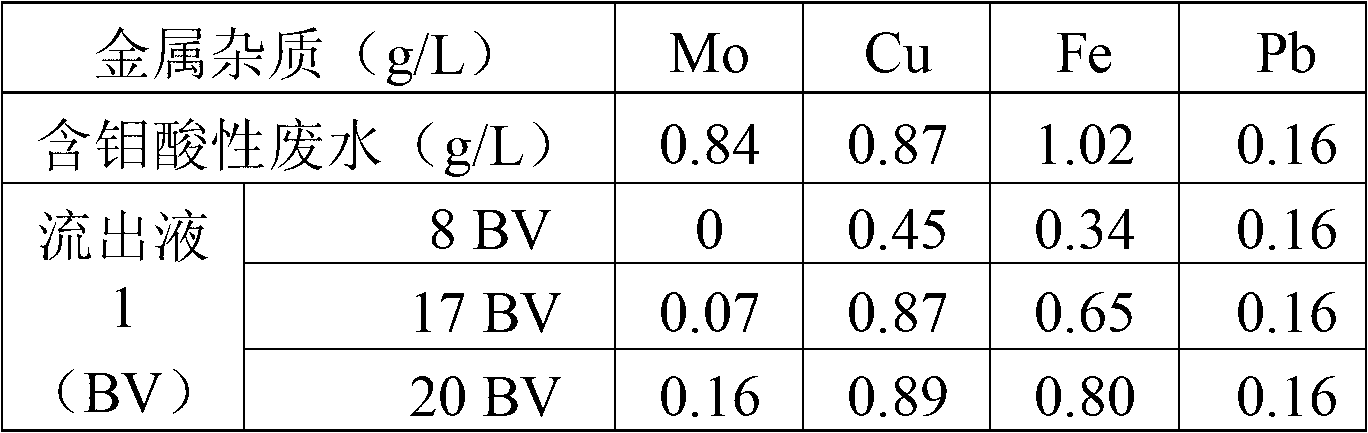

[0032] (1) Add aminophosphonic acid chelating resin with a wet volume of 100mL to the φ25×400mm glass exchange column 1, of which the volume of the dry resin is 80mL, which becomes 100mL after adding water; a high level bottle 1 is connected above the glass exchange column 1; The molybdenum-containing acidic wastewater produced by the traditional production process of ammonium molybdate containing the nitric acid leaching step is filtered to remove suspended impurities, then added to the high level bottle 1, passed through the aminophosphonic acid chelating resin column at room temperature, and collected to obtain 2000mL effluent 1;

[0033] Wherein, the flow velocity of molybdenum-containing acidic wastewater is 2BV / h; when the peraminophosphonic acid chelating resin is saturated, adopt 3wt% ammonia water as the anal...

Embodiment 2

[0049] A treatment method for molybdenum-containing acidic waste water produced in the ammonium molybdate production process, the concrete steps are as follows:

[0050] (1) Add aminophosphonic acid chelating resin with a wet volume of 100mL to the φ25×400mm glass exchange column 1, of which the volume of the dry resin is 80mL, which becomes 100mL after adding water; a high level bottle 1 is connected above the glass exchange column 1; The molybdenum-containing acidic wastewater produced by the traditional production process of ammonium molybdate containing nitric acid leaching steps is filtered to remove suspended impurities, then added to the high level bottle 1, and passed through the aminophosphonic acid chelating resin column at room temperature to collect 2060mL of effluent 1;

[0051] Wherein, the flow rate of molybdenum-containing acidic wastewater is 2BV / h; when the peraminophosphonic acid chelating resin is adsorbed and saturated, 4wt% ammonia water is used as the ana...

Embodiment 3

[0067] A treatment method for molybdenum-containing acidic waste water produced in the ammonium molybdate production process, the concrete steps are as follows:

[0068] (1) Add aminophosphonic acid chelating resin with a wet volume of 100mL to the φ25×400mm glass exchange column 1, of which the volume of the dry resin is 80mL, which becomes 100mL after adding water; a high level bottle 1 is connected above the glass exchange column 1; The molybdenum-containing acidic wastewater produced by the traditional production process of ammonium molybdate containing the nitric acid leaching step is filtered to remove suspended impurities, then added to the high level bottle 1, and passed through the aminophosphonic acid chelating resin column at room temperature, and 1830 mL of the effluent 1 is collected;

[0069] Wherein, the flow velocity of molybdenum-containing acidic wastewater is 2BV / h; when the peraminophosphonic acid chelating resin is saturated, adopt 5wt% ammonia water as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com