Normal temperature low-ammonia-nitrogen nitrosation starting method

A low-ammonia nitrogen nitrification and nitrosation technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve problems such as failure, narrow applicability, and singleness, and achieve speed improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

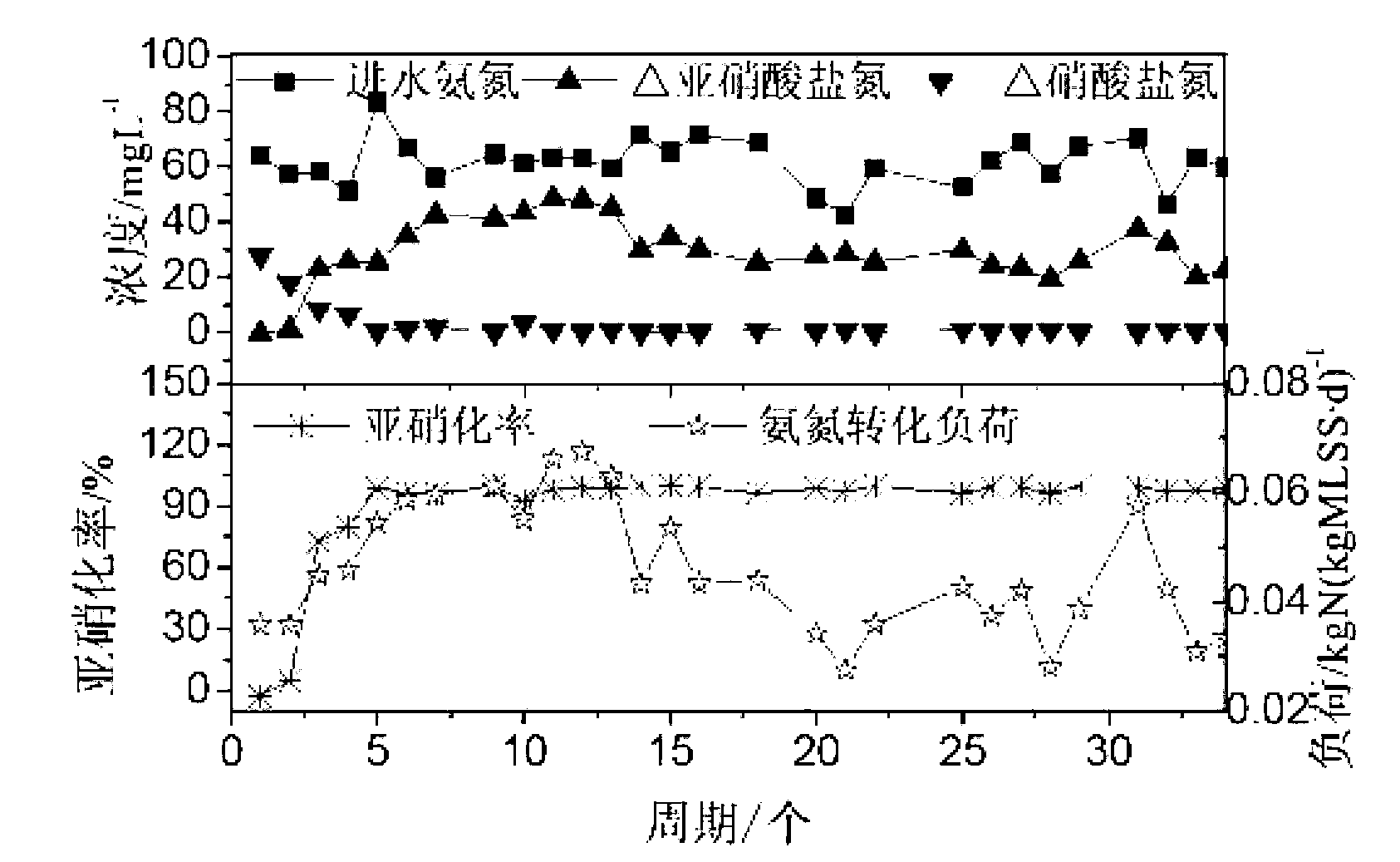

[0030] Example 1 see figure 1

[0031] The inoculation sludge of 1# reactor comes from the nitrification sludge of Beijing Municipal A Wastewater Treatment Plant. It adopts artificial water distribution, and directly operates with limited oxygen after inoculation. The dissolved oxygen concentration is controlled at 0.30~0.40mg / L. The initial nitrosation rate of inoculated sludge in 1# reactor was 50%, indicating that the inoculated sludge has certain nitrosation performance. The difference in affinity between AOB and NOB for dissolved oxygen can be used, and the initial accumulation of nitrite nitrogen can be achieved through oxygen limitation control. In the 1-14 cycle, the sludge is in the adaptation period of low oxygen conditions, the sedimentation effect is reduced, and the treatment effect is not stable. With continuous acclimatization under oxygen-limited conditions, the nitrosation rate gradually increased. After 7 days (14 cycles) of acclimatization, the ammonia ni...

Embodiment 2

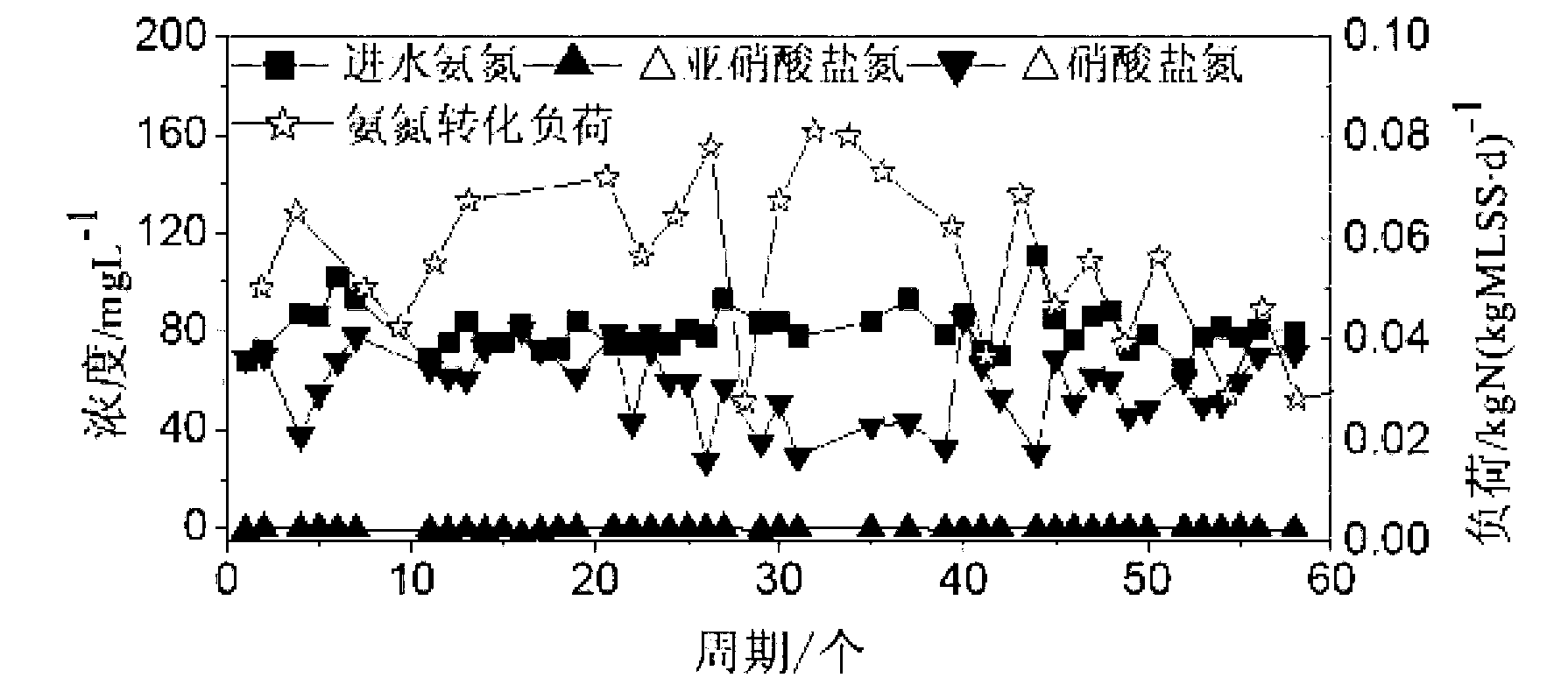

[0032] Example 2 see figure 2

[0033] The inoculum sludge of 2# reactor comes from the nitrification sludge of B sewage treatment plant in Beijing. In the determination test of the initial properties of the inoculated sludge, no accumulation of nitrite nitrogen was found, and the initial nitrification rate was almost 0%, which was the whole process of nitrification sludge.

[0034]2# adopts the same water distribution plan and start-up strategy as 1#, and operates under the condition of oxygen limitation (DO=0.30~0.40mg / L). However, after 30 days (58 cycles) of cultivation, there was no accumulation of nitrite nitrogen in the water. In the periodic test, nitrite was not seen as an intermediate product, and ammonia nitrogen was directly oxidized to nitrate. The conversion load of ammonia nitrogen is also low, ranging from 0.028 to 0.069 kgN / kgMLSS / d. The 2# reactor was artificially distributed with water, and the concentration of ammonia nitrogen in the influent water was...

Embodiment 3

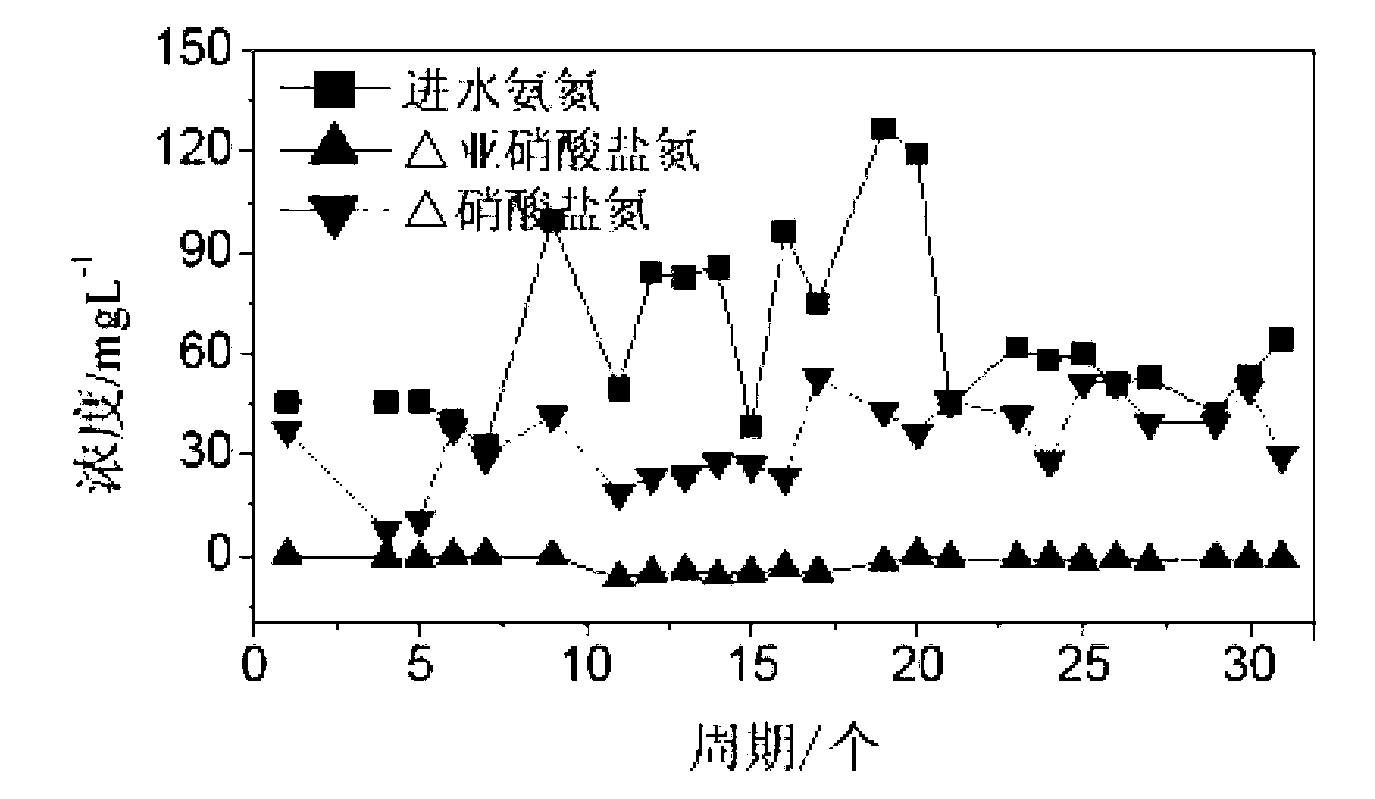

[0035] Embodiment 3 see image 3

[0036] The inoculum sludge of 3# reactor comes from the nitrification sludge of B sewage treatment plant in Beijing. In the determination test of the initial properties of the inoculated sludge, no accumulation of nitrite nitrogen was found, and the initial nitrification rate was almost 0%, which was the whole process of nitrification sludge.

[0037] The effluent of a septic tank in a residential area in Beijing was treated by A / O phosphorus removal process as influent water to start nitrosation, and the COD in the influent water was 43.05±12.35mg / L. After 30 days (32 cycles) of operation under oxygen-limited conditions (DO=0.30~0.40mg / L), there was no accumulation of nitrite nitrogen in the effluent, and all ammonia nitrogen was oxidized to nitrate nitrogen. During the cycle test, no accumulation of nitrite was found. The 4# reactor passed the A / O secondary effluent, and the concentration of ammonia nitrogen in the influent water was 85....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com