Method for producing sodium sulfate and sodium nitrate by simultaneous desulfurization and denitrification by soda-citric acid cobalt (II)

A technology of citric acid and sodium sulfate, applied in the direction of alkali metal sulfite/sulfite, alkali metal nitrate, chemical instruments and methods, etc., can solve the secondary pollution of solid waste, cannot recycle sulfur resources, sulfurous acid Low calcium efficiency and other issues, to achieve the effect of high operating costs, high desulfurization and denitrification rate, and large mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

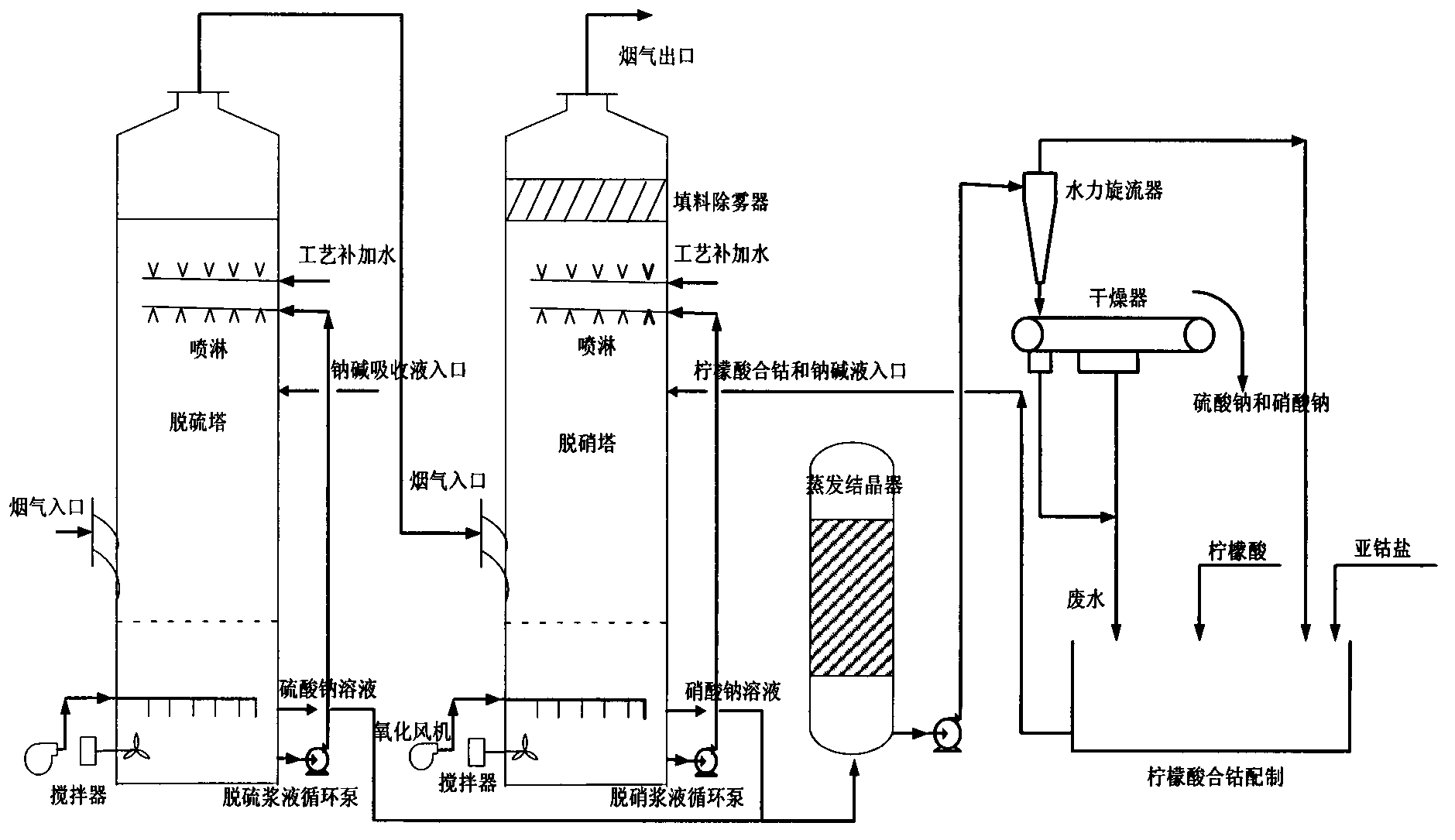

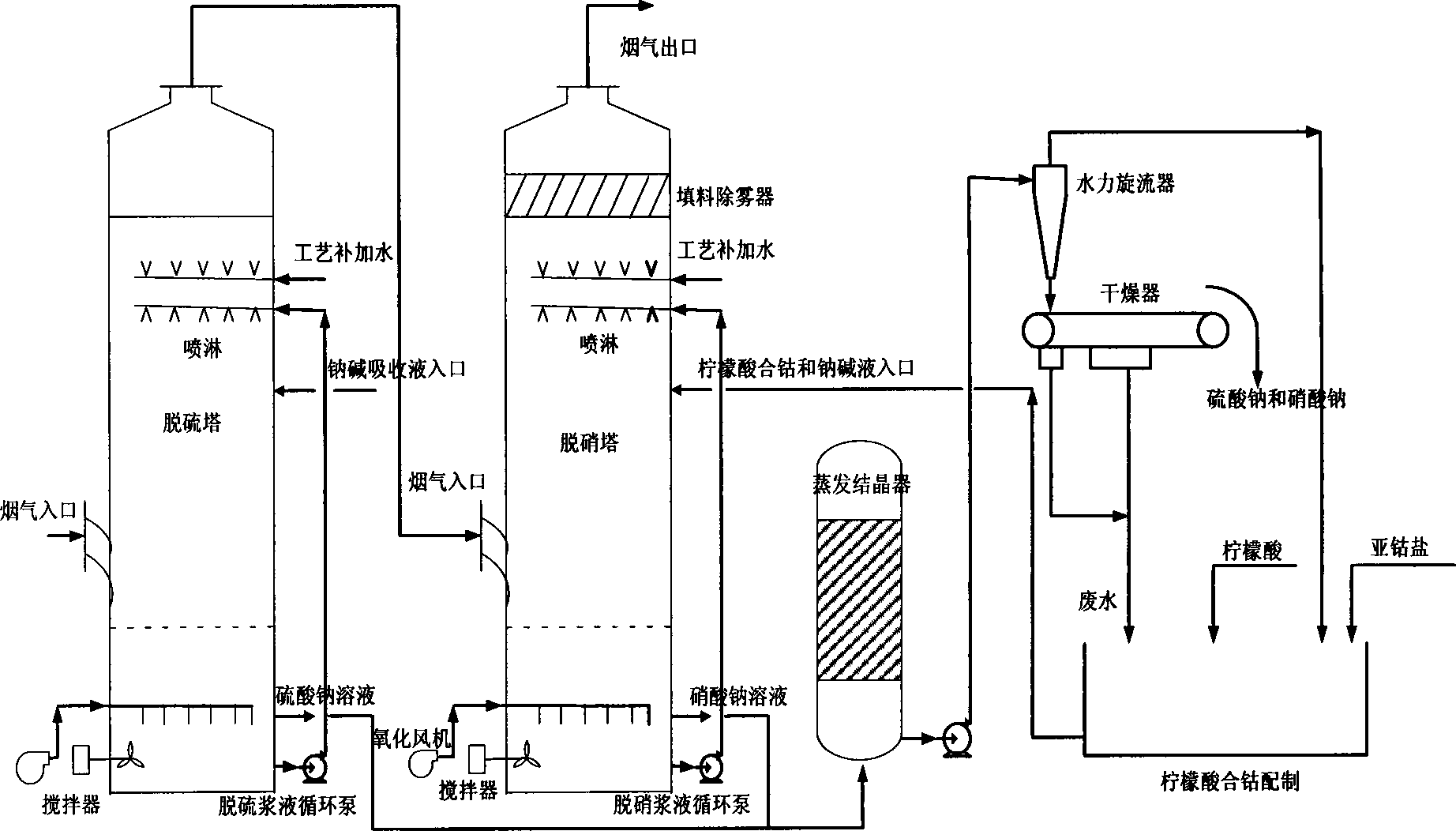

[0030] The flue gas desulfurization and denitrification test is carried out in the device shown in the attached figure. The spray tower is a glass spray tower with a diameter of 75mm and a height of 100mm. The gas-liquid two-phase countercurrent flow is 30m in the desulfurization tower. 3 / h, 120L / h of liquid absorption liquid, temperature is 50℃, pH value is 5.5, SO 2 The inlet concentration is 2100ppm, the mass concentration of sodium ions is 5%; the gas flow in the denitrification tower is 30m 3 / h, the liquid spray volume is 100L / h, the temperature is 40°C, the pH value is 8, the NO inlet concentration is 800ppm, the sodium ion concentration is 6%, and the cobalt citrate concentration is 0.10mol / L. SO in flue gas 2 The import and export concentrations of NO and NO were measured by the KM940 flue gas analyzer of the British Kane Company, and the SO was exported after the operation was stable. 2 The concentration is 100ppm, the desulfurization rate is 95.2%, the NO outlet ...

Embodiment 2

[0032] The test device and desulfurization operating conditions are the same as in Example 1, except that the operating conditions of the denitrification tower are changed, and the gas flow in the denitrification tower is 30m 3 / h, the liquid spray volume is 100L / h, the temperature is 40°C, the pH value is 10, the NO inlet concentration is 800ppm, the sodium ion concentration is 6%, and the cobalt citrate concentration is 0.10mol / L. Export SO after stable operation 2 The concentration is 100ppm, the desulfurization rate is 95.2%, the NO outlet concentration is 46ppm, and the desulfurization rate is 94.3%.

Embodiment 3

[0034] The test device is the same as in Example 1, and the gas flow in the desulfurization tower is 20m 3 / h, 80L / h of liquid absorption liquid, temperature is 50°C, pH value is 6, SO 2 The inlet concentration is 3000ppm, the concentration of sodium ion is 6%; the gas flow rate in the denitrification tower is 20m 3 / h, the liquid spray volume is 60L / h, the temperature is 40°C, the pH value is 10, the NO inlet concentration is 600ppm, the sodium ion concentration is 6%, and the cobalt citrate concentration is 0.15mol / L. SO in flue gas 2 The import and export concentrations of NO and NO were measured by the KM940 flue gas analyzer of the British Kane Company, and the SO was exported after the operation was stable. 2 The concentration is 102ppm, the desulfurization rate is 96.6%, the NO outlet concentration is 60ppm, and the desulfurization rate is 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com