Composite sun-screening agent nano-structure lipid carrier and preparation method thereof

A technology of nano-structured lipids and composite lipids, which is applied in pharmaceutical formulations, cosmetic preparations, toiletry preparations, etc., can solve problems such as low loading, low stability of sunscreens, and inability of sunscreens to protect against UV rays. The effect of increasing the loading capacity, reducing drug leakage, and increasing the SPF value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 Preparation of novel composite sunscreen agent nanostructure lipid carrier

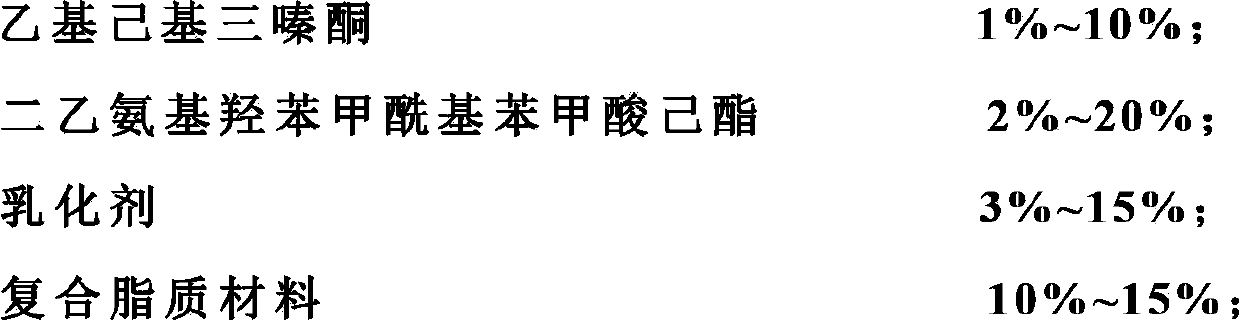

[0037] Composition formula

[0038]

[0039] like figure 1 Shown, the preparation steps of this embodiment are as follows:

[0040] 1. Weigh 9.6 grams of ceteareth-6 olive oil, 2.4 grams of cetearyl olive oil, 1.5 grams of acetylated monoglycerides, and 13.5 grams of caprylyl capric acid glycerides into a beaker , heated in a water bath at 75°C.

[0041] 2. After the lipid and emulsifier in the beaker are completely melted, add 1.7 g of ethylhexyl triazone and 3.3 g of diethylamino hydroxybenzoyl hexyl benzoate, and heat to dissolve for 30 minutes.

[0042] 3. Weigh 68.0 g of deionized water into a beaker, and heat in a water bath at 75°C.

[0043] 4. Add the water phase to the above system, stir evenly, and at the same time, turn on the high-pressure homogenizer and preheat it with 75°C deionized water;

[0044] 5. Inject the uniformly stirred high-temperature emulsion syste...

Embodiment 2

[0046] Embodiment 2 Preparation of novel composite sunscreen agent nanostructure lipid carrier

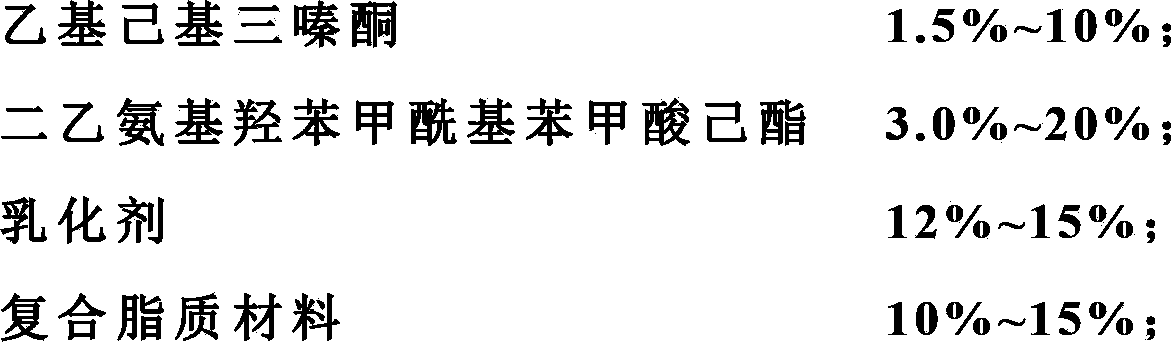

[0047] Composition formula

[0048]

[0049]

[0050] Preparation steps:

[0051] 1. Weigh 9.6 grams of ceteareth-6 olive oil, 2.4 grams of cetearyl olive oil, 1.5 grams of acetylated monoglycerides, 12.0 grams of glyceryl caprylate, 1.5 grams Glyceryl monostearate was put into a beaker and heated in a water bath at 75°C.

[0052] 2. After the lipid and emulsifier in the beaker are completely melted, add 3.3 grams of ethylhexyl triazone and 6.7 grams of diethylamino hydroxybenzoyl hexyl benzoate, and heat to dissolve for 30 minutes.

[0053] 3. Weigh 63.0 g of deionized water into a beaker, and heat it in a water bath at 75°C.

[0054] 4. Add the water phase to the above system, stir evenly, and at the same time, turn on the high-pressure homogenizer and preheat it with 75°C deionized water;

[0055] 5. Inject the uniformly stirred high-temperature emulsion system into a ...

Embodiment 3

[0057] Example 3 Preparation of Novel Composite Sunscreen Agent Nanostructured Lipid Carrier

[0058] Composition formula

[0059]

[0060] Preparation steps:

[0061] 1. Weigh 9.6 grams of ceteareth-6 olive oil, 2.4 grams of cetearyl olive oil, 1.5 grams of acetylated monoglycerides, 12.0 grams of glyceryl caprylate, 1.5 grams Glyceryl monostearate was put into a beaker and heated in a water bath at 75°C.

[0062] 2. After the lipid and emulsifier in the beaker are completely melted, add 10.0 g of ethylhexyl triazone and 20.0 g of diethylamino hydroxybenzoyl hexyl benzoate, and heat to dissolve for 30 minutes.

[0063] 3. Weigh 43.0 g of deionized water into a beaker, and heat it in a water bath at 75°C.

[0064] 4. Add the water phase to the above system, stir evenly, and at the same time, turn on the high-pressure homogenizer and preheat it with 75°C deionized water;

[0065] 5. Inject the uniformly stirred high-temperature emulsion system into a high-pressure homoge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com