Copper alloy sheet and process for producing same

A manufacturing method and technology of copper alloys, applied in the direction of metal/alloy conductors, conductive materials, conductive materials, etc., can solve the problems of reduced contact pressure of contact parts, increased contact resistance of contact parts, cracks in materials, etc., to achieve excellent bending workability , the effect of excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Using a high-frequency melting furnace, as shown in the composition of the alloy composition column in Table 1-1, Si containing at least one or both of Ni and Co in a total of 0.5 to 5.0 mass % and 0.1 to 1.5 mass % , an alloy whose balance is Cu and unavoidable impurities is melted, and cast to obtain an ingot. Using this state as a feedstock, test materials of the copper alloy sheet materials of Examples 1-1 to 1-19 of the present invention and Comparative Examples 1-1 to 1-9 were produced through any of the following steps A to F.

[0091] (Process A)

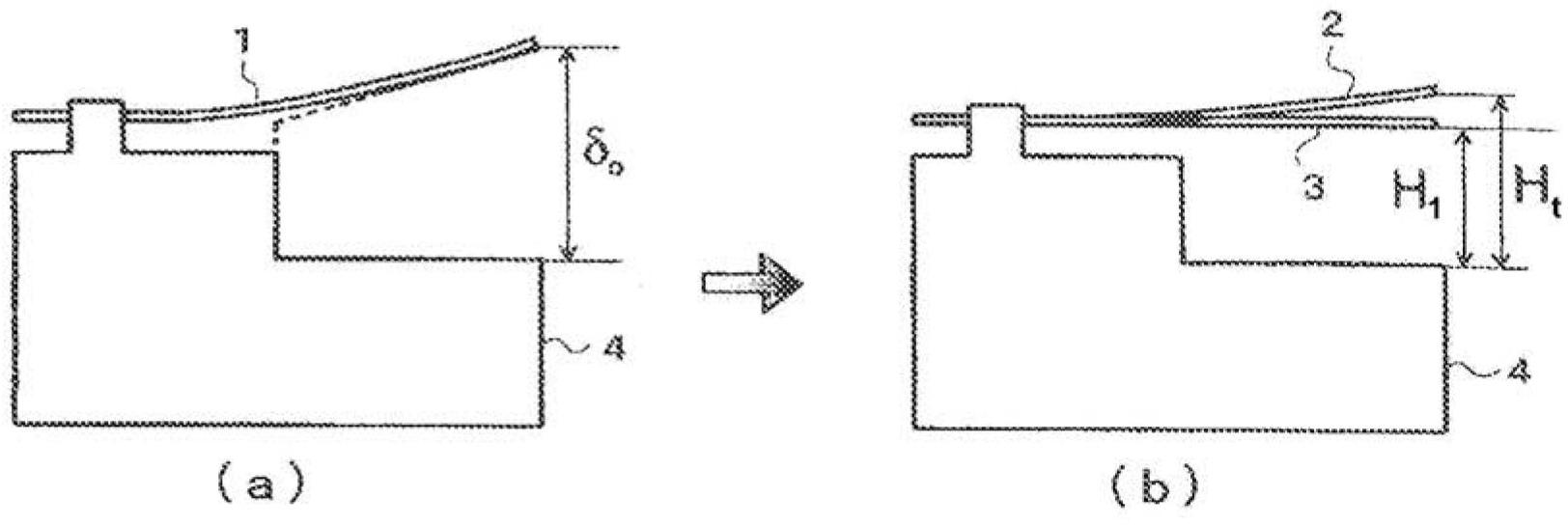

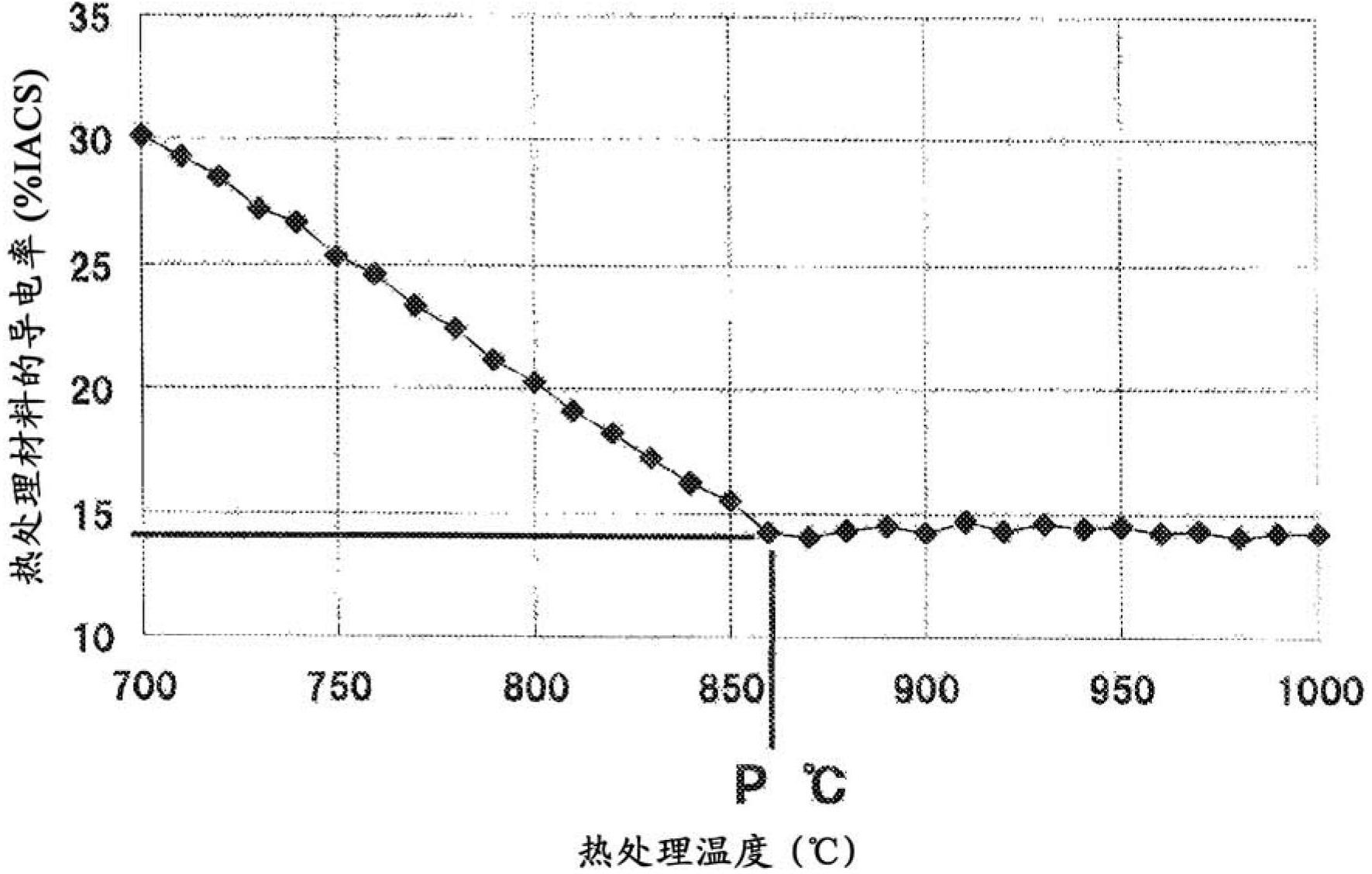

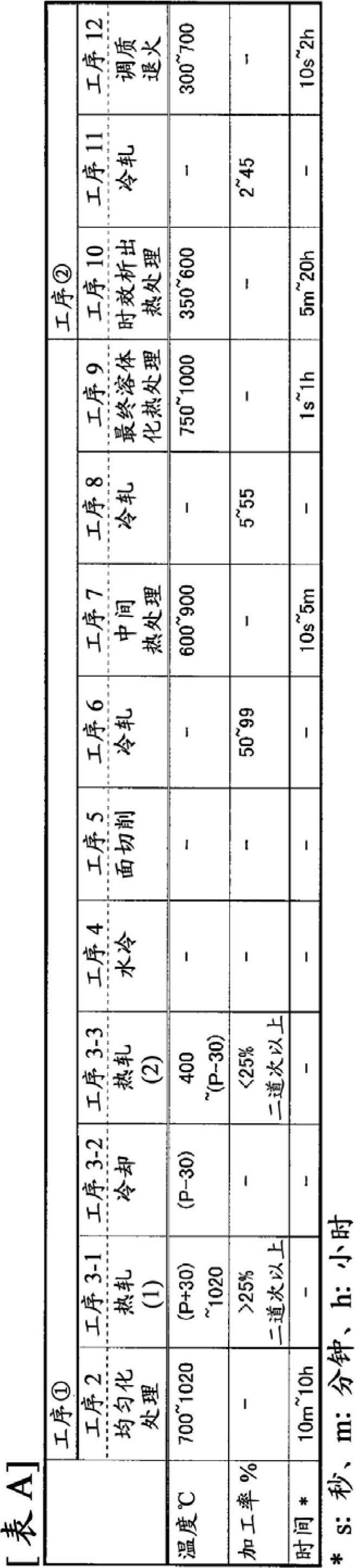

[0092] Homogenizing heat treatment for 10 minutes to 10 hours at 1020~700°C, three passes of hot rolling at a temperature range of 1020~(P+30)°C at a processing rate of more than 25%, air cooling, in (P-30) In the temperature range of ~4000C, three passes of hot rolling, water cooling, 50~99% cold rolling, heat treatment at 600~900°C for 10 seconds~5 minutes, 5~55% processing at a processing rate below 25% High-spee...

Embodiment 2

[0127] For a copper alloy having the composition shown in the column of the alloy composition of Table 2 and the balance being Cu and unavoidable impurities, Examples 2-1 to 2-17 of the present invention and Comparative Example 2-1 were produced in the same manner as in Example 1. The test materials of the copper alloy sheets of 1 to 2-3 were investigated in the same manner as in Example 1 for their characteristics. The results are shown in Table 2.

[0128]

[0129] As shown in Table 2, Invention Example 2-1 to Invention Example 2-17 were excellent in bending workability, yield strength, electrical conductivity, and stress relaxation resistance.

[0130] On the other hand, in the case where the stipulations of the present invention are not satisfied, the characteristics are inferior. That is, Comparative Examples 2-1, 2-2, and 2-3 (all of which are comparative examples of the invention of the above item (3)) have poor electrical conductivity due to the addition of a large...

Embodiment 3

[0132] For copper alloys with the composition shown in Table 3, and the balance is Cu and unavoidable impurities, after the ingot is subjected to a homogenization heat treatment at 1020~700°C for 10 minutes to 10 hours, the copper alloy shown in Table 4 After hot rolling, water cooling, face cutting, 50-99% cold rolling, heat treatment at 600-900°C for 10 seconds to 5 minutes, cold working at 5-55% processing rate, 50% at 750-1000°C Second ~ 1 hour final solution heat treatment. Then, carry out aging precipitation heat treatment at 350~600°C for 5 minutes~20 hours, finish rolling at 2~45% processing rate, and temper annealing at 300~700°C for 10 seconds~2 hours. test material. The characteristics were investigated in the same manner as in Example 1. The results are shown in Table 4.

[0133] [table 3]

[0134] Composition element

Ni

co

Si

sn

Zn

Mg

Cr

quality%

2.71

0.32

0.76

0.17

0.31

0.07

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com