A kind of lithium-ion battery cathode material recovery method

A lithium-ion battery and positive electrode material technology, applied in the field of battery materials, can solve the problems of incomplete impurity treatment, long process, harsh operating environment, etc., to improve energy utilization, eliminate environmental damage, and solve the effects of high magazine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

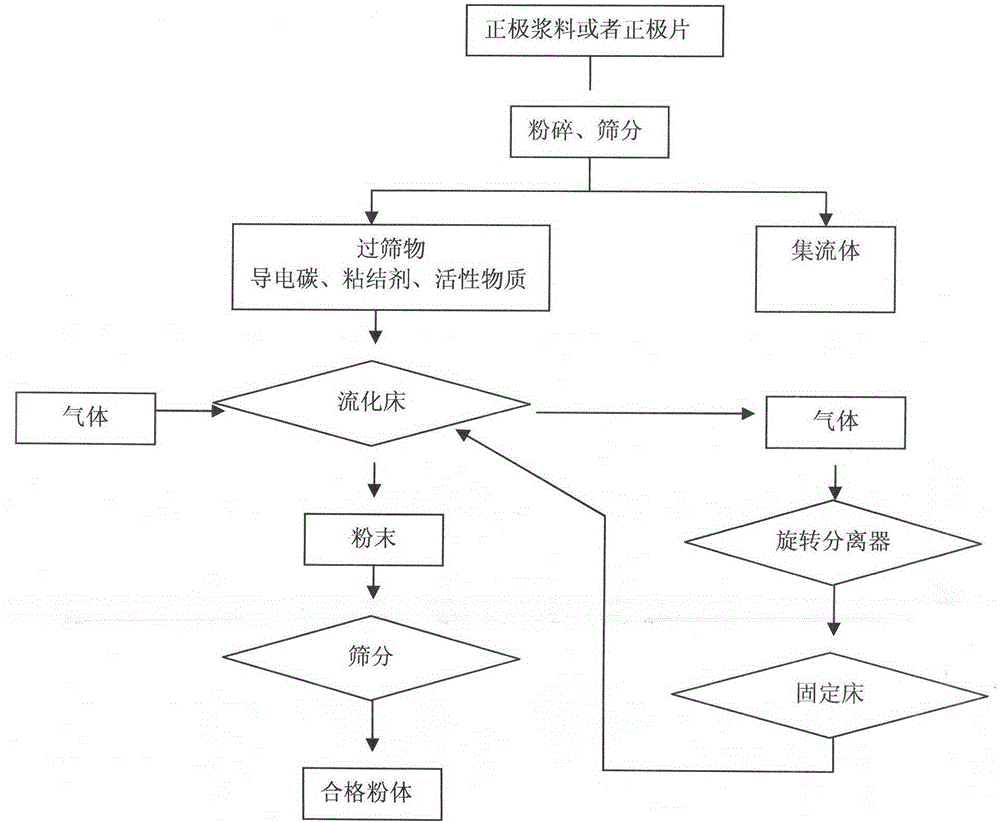

Method used

Image

Examples

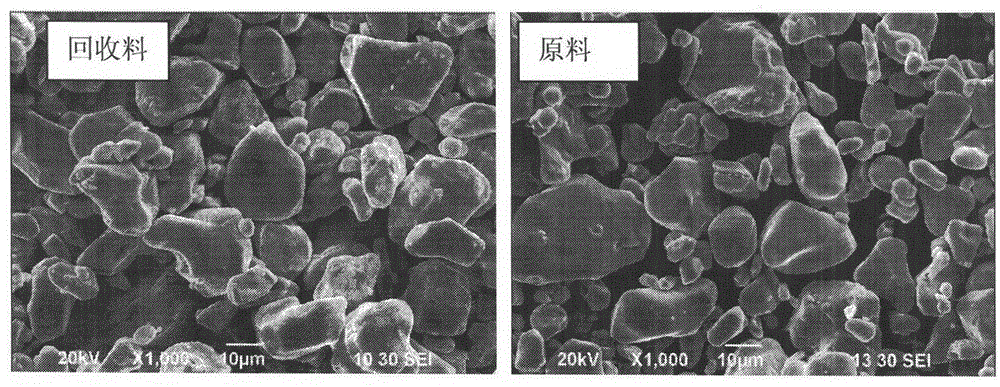

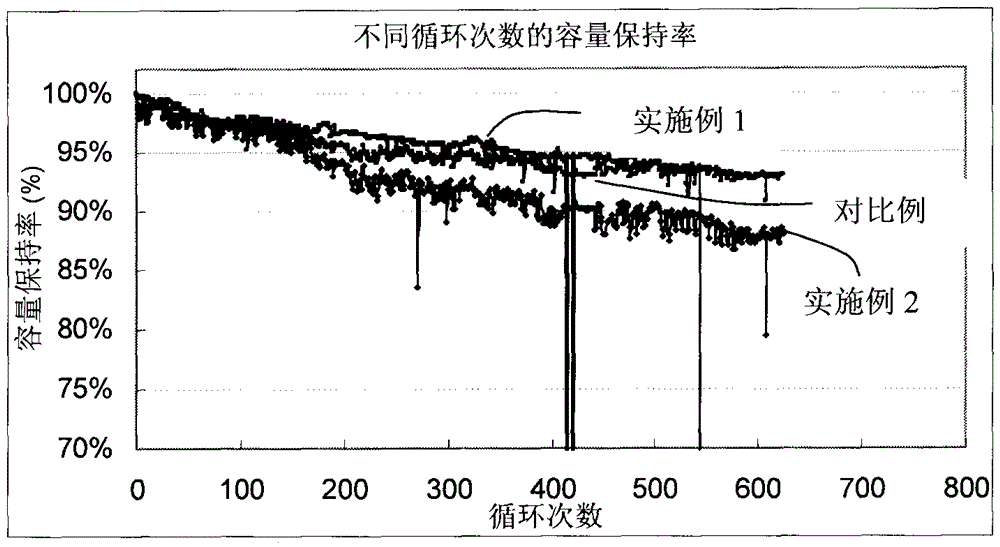

Embodiment 1

[0035] Take 30kg of dry slurry to be recovered and put it into a pulverizer, put it into the pulverizer in batches, and after pulverizing for 10-60 minutes, pulverize into particles smaller than 5mm. Then use a 10-mesh to 200-mesh vibrating sieve to sieve the powder. The materials that do not pass through the 200-mesh sieve are further crushed and screened out, and finally a small part of the debris that cannot be filtered can be discarded. Weigh 28.5kg, add the powder from the feeding port, the gas is heated to 600°C by the heater, and enter the reactor from the bottom of the fluidized bed, and adjust the gas inlet flow rate to 8.5m 3 / h~40m 3 / h, the average residence time of the powder is 60min. After the gas passes through the cyclone separator to separate the entrained powder, it enters the fixed bed with CaO particles, and then the gas is heated and recycled. 4) After the bottom powder is cooled, use a 100-mesh to 300-mesh sieving machine to obtain qualified positive ...

Embodiment 2

[0037] Take 30kg of positive electrode pieces to be recovered and load them into a pulverizer, put them into a mixer in batches, and add an appropriate amount of zirconium glass beads for powder removal. Then sieve the processed pole piece powder with a 10-mesh to 200-mesh vibrating sieve. The materials that do not pass through the 200-mesh sieve are further crushed and screened out, and finally a small part of the debris that cannot be filtered can be discarded. Weigh 22.7kg, add the powder from the feeding port, add the powder from the feeding port, heat the gas to 600°C through the heater, and adjust the gas inlet flow rate to 8.5m 3 / h~40m 3 / h, the average residence time of the powder is 60min. After the gas passes through the cyclone separator to separate the powder, it enters the fixed bed with CaO particles, and then the gas is heated and recycled. 4) After the bottom powder is cooled, use a 100-mesh to 300-mesh sieving machine to obtain qualified positive electrode...

Embodiment 3

[0039] The difference from Example 1 is that the gas heating temperature is 750°C. Others are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com