Multi-color glasses frame blank and shell profile shapes blank as well as molding equipment thereof

A technology for forming equipment and profiled materials, applied in glasses/goggles, optics, instruments, etc., can solve the problems of low processing efficiency, waste of raw materials, less color and style changes, etc., to reduce working hours, reduce cutting production processes, and save money. The effect of working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

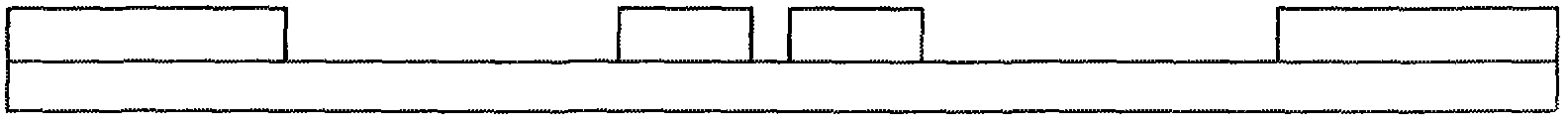

[0059] A multi-color spectacle frame, watch case profile blank and its molding equipment are used to produce an extended multi-color plasticized cellulose diacetate, TR90 or other related nylon materials similar to TR90, nylon elastomer or Nylon alloy material with a special shape. The shape of this profile is an extruded hollow profile with a hollow full orbit or a solid half eye frame. The finished product of the hollow eye socket or solid half eye frame profile is further cut by semi-manual or automatic forming machine tools. Processed semi-finished glasses.

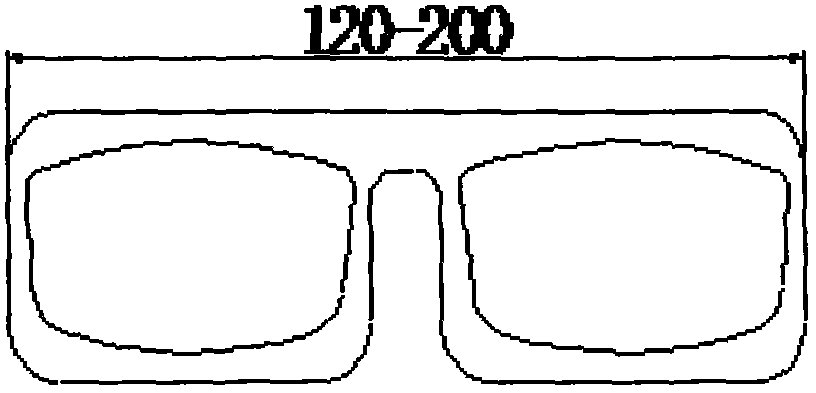

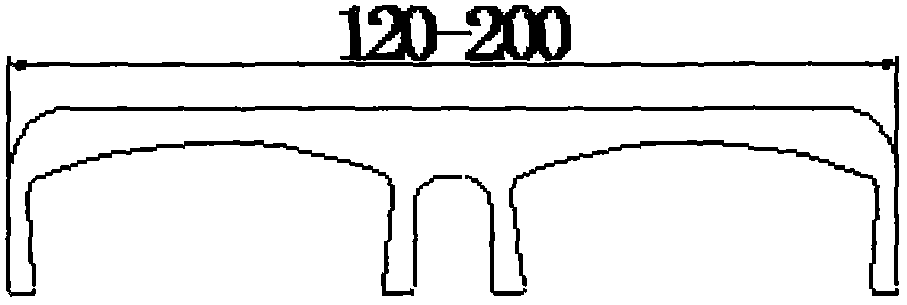

[0060] see Figure 1 to Figure 9 , the present invention provides a multi-color spectacle frame profile blank, the blank is a long profile profile, the width of which is 120-200mm, the thickness is 20-66mm, and the length can be set according to the design of the shearing ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com