Novel stress sensor based on magnetoresistance effect

A stress sensor and magnetoresistance technology, applied in the field of sensing, can solve the problems of complex structure, high production cost, poor fatigue resistance, etc., and achieve the effects of mature technology, sensitive response and simple circuit design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

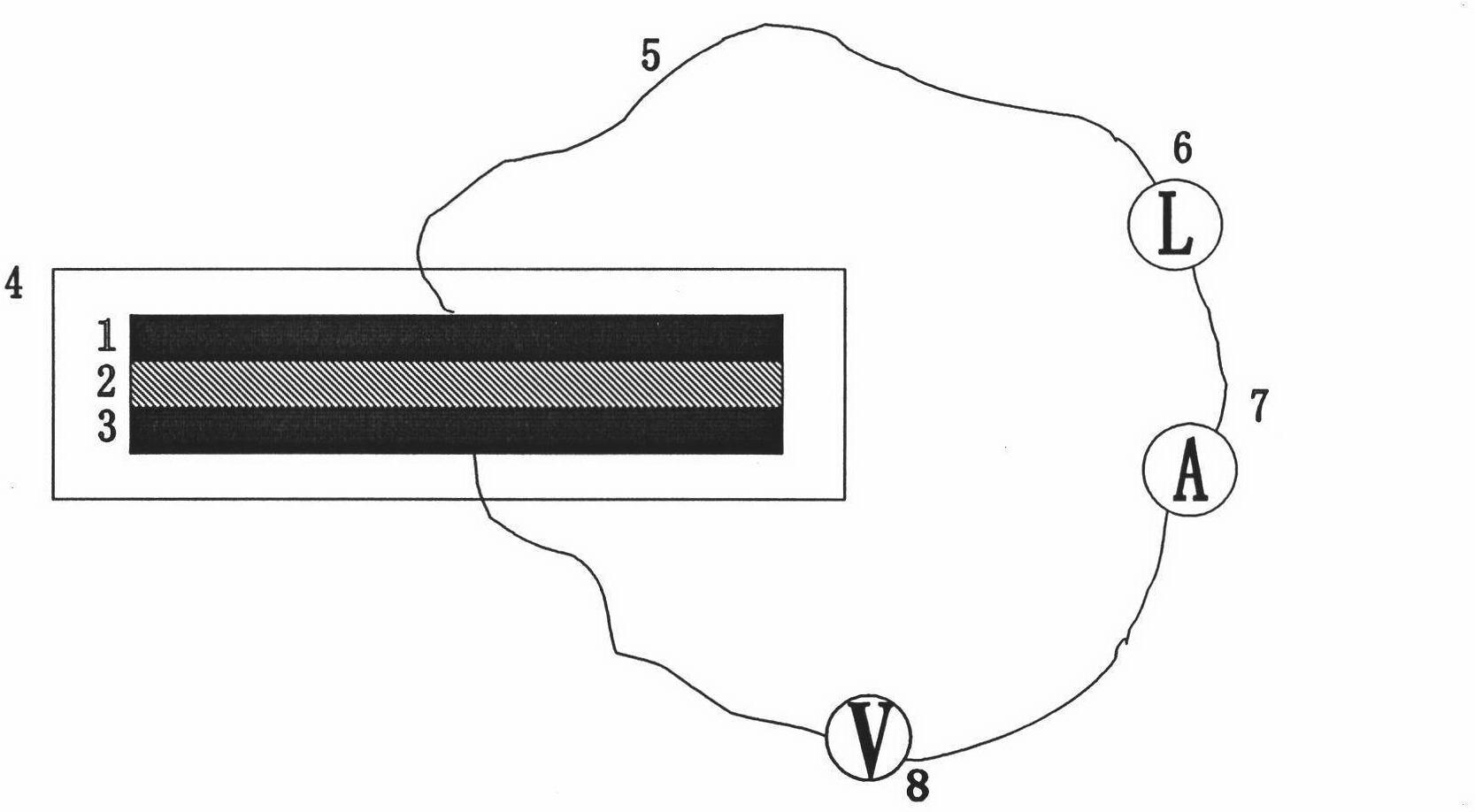

[0013] like figure 1 , figure 2 Shown:

[0014] The upper layer is the upper ferromagnetic layer 1, the middle layer is the non-magnetic layer 2, and the lower layer is the lower ferromagnetic layer 3; then the above part is wrapped with a wrapping layer 4, and the wrapping layer 4 is made of polyimide film Made; then use wire 5 to pass through wrapping layer 4 to connect with upper ferromagnetic layer 1, the other end of wire 5 is connected in series with indicator light 6, ammeter 7, power supply 8 and then pass through wrapping layer 4 to connect with lower ferromagnetic layer 3; The signs of the magnetostriction coefficients of the upper ferromagnetic layer 1 and the lower ferromagnetic layer 3 are opposite; the conductive non-magnetic layer 2 forms a spin valve system together with the separated upper ferromagnetic layer 1 and lower ferromagnetic layer 3 .

[0015] The concrete application process description of the present invention:

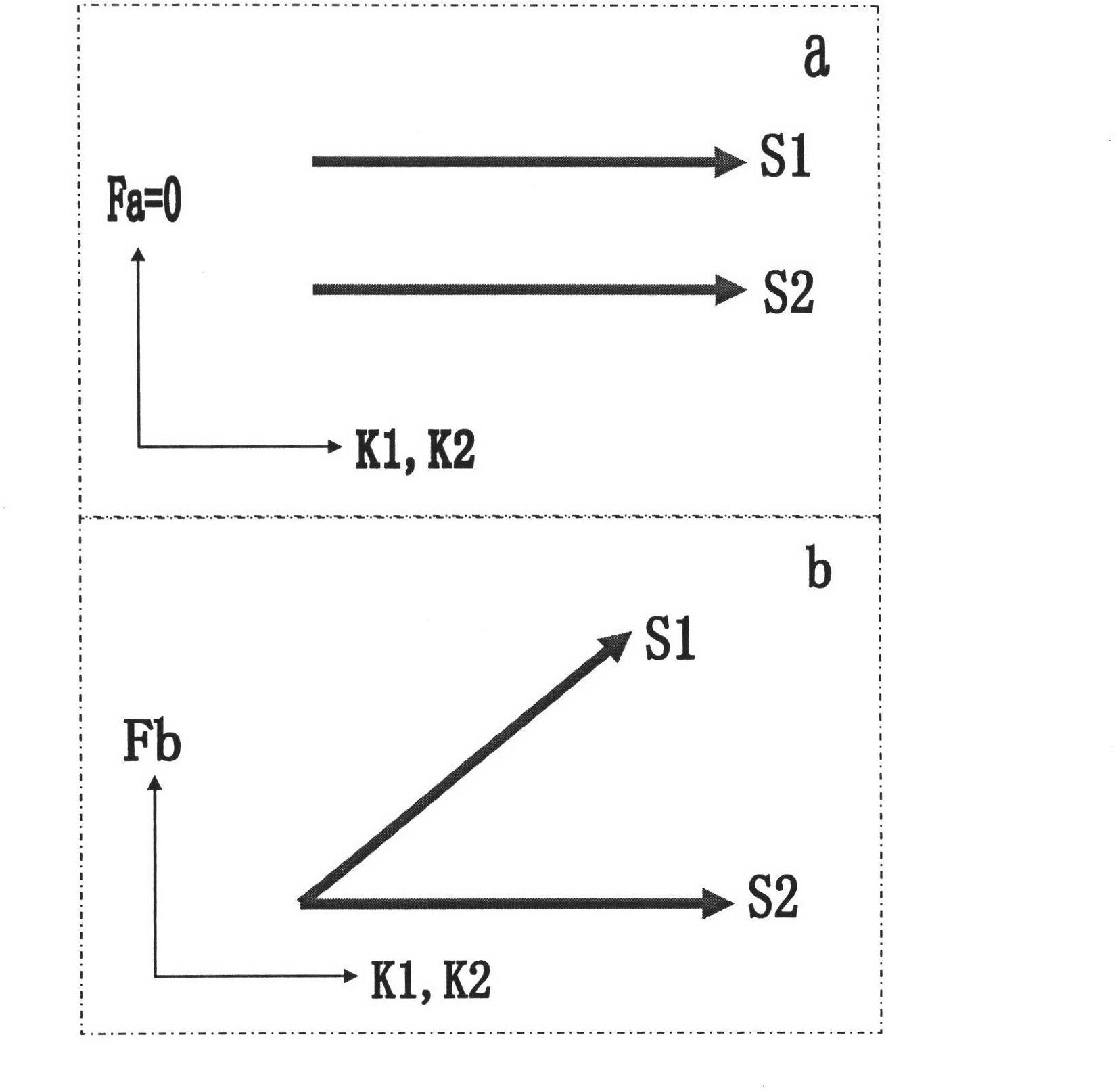

[0016] When the environmental s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com