Heat-resisting material and preparing method thereof as well as base station antenna outer cover

A technology with high temperature resistance and inorganic fillers, which is applied in the field of materials, can solve the problems of high manufacturing cost, poor quality, the end cover of the antenna cover and the waterproof of the antenna cover, etc., and achieve the effect of improving heat resistance and deformation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

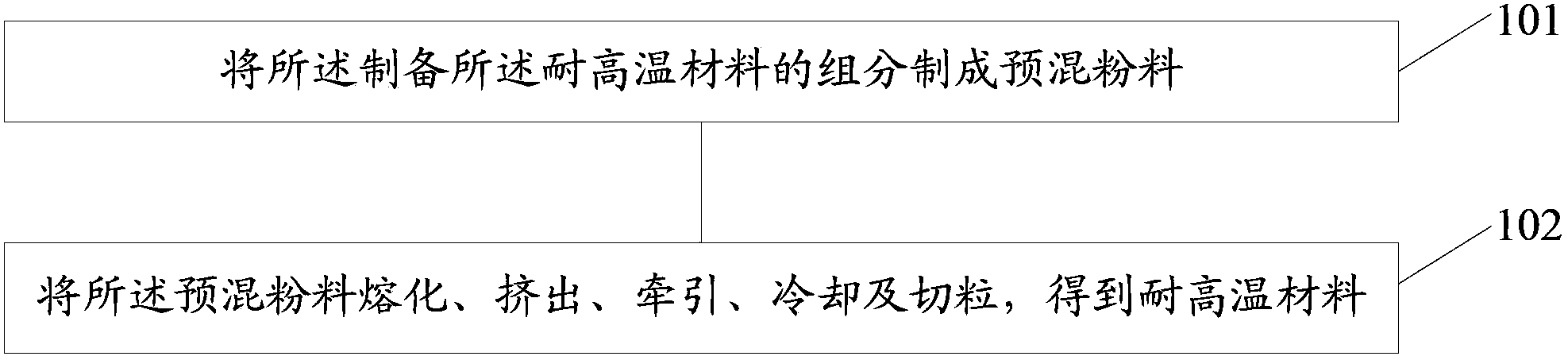

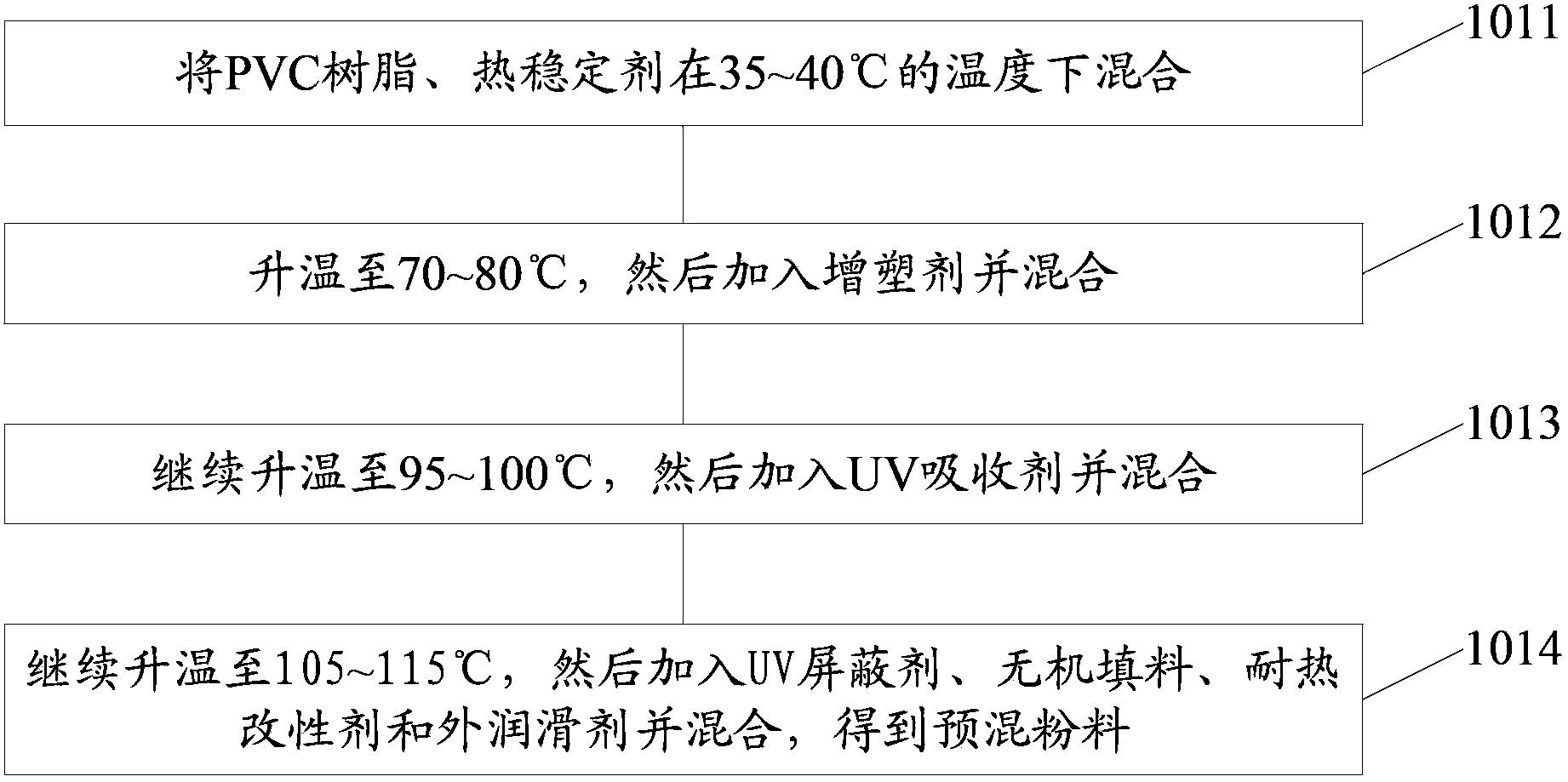

[0059] Correspondingly, the embodiment of the present invention also provides a preparation method of the above-mentioned high temperature resistant material, such as figure 1 shown, including:

[0060] 101. Making the components for preparing the high temperature resistant material into premixed powder;

[0061] Wherein, the components for preparing high-temperature-resistant materials include polyvinyl chloride PVC resin, heat-resistant modifier, ultraviolet UV absorber, UV shielding agent, heat stabilizer, inorganic filler, external lubricant and plasticizer;

[0062] The heat-resistant modifier is selected from at least one of N-phenyl substituted maleimide and N-cyclohexane substituted maleimide;

[0063] Wherein, the mass parts of the components for preparing the high-temperature-resistant material are: PVC resin: 100 parts, heat-resistant modifier: 3-15 parts, UV absorber: 0.05-1 part, UV shielding agent: 2-10 parts 15 parts, heat stabilizer: 2~10 parts, inorganic fil...

Embodiment 1

[0085] An embodiment of the present invention provides a high temperature resistant material. Wherein, the components and the mass parts of the components for preparing the high temperature resistant material are:

[0086]PVC resin: 100 parts; N-phenyl substituted maleimide: 10 parts; primary antioxidant 1010: 0.3 parts; auxiliary antioxidant triphenyl phosphite: 0.5 parts; UV312: 0.05 parts; rutile titanium dioxide : 15 parts; Ca / Zn series stabilizer: 2 parts; ultrafine activated calcium carbonate: 10 parts; alkali-free glass fiber: 15 parts; oxidized PE wax: 2 parts; stearic acid: 0.3 parts; Sex agent: 6 parts. Wherein, the composite impact modifier is obtained by mixing chlorinated polyethylene and powdered nitrile rubber at a mass ratio of 1:0.8.

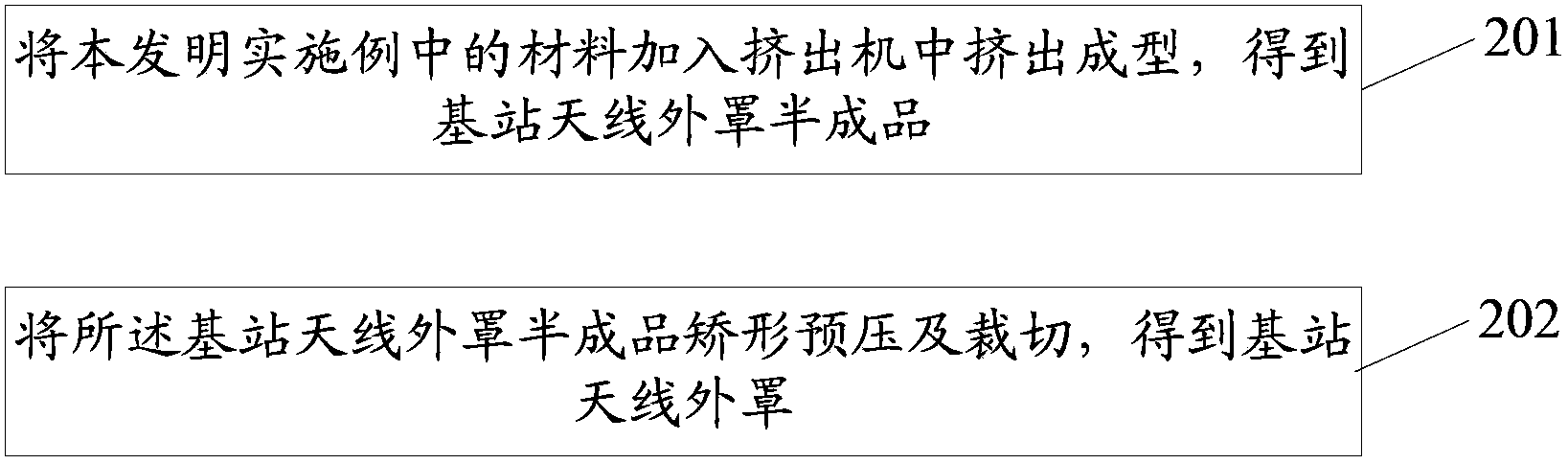

[0087] An embodiment of the present invention also provides a base station antenna cover, and the base station antenna cover is made of the above high temperature resistant material.

[0088] Embodiments of the present invent...

Embodiment 2

[0100] An embodiment of the present invention provides a high temperature resistant material. Wherein, the components and the mass parts of the components for preparing the high temperature resistant material are:

[0101] PVC resin: 100 parts; N-phenyl substituted maleimide: 8 parts; primary antioxidant 1010: 0.6 parts; auxiliary antioxidant phenylenedioctyl phosphite: 2 parts; UV531: 0.2 parts, UV571 : 0.1 parts; rutile titanium dioxide: 6 parts; Ca / Zn series stabilizer: 5 parts; ultrafine activated calcium carbonate: 25 parts; alkali-free glass fiber: 5 parts; oxidized PE wax: 2.5 parts; stearic acid: 0.4 parts; composite impact modifier: 8 parts. Wherein, the composite impact modifier is obtained by mixing chlorinated polyethylene and powdered nitrile rubber at a mass ratio of 1:1.2.

[0102] An embodiment of the present invention also provides a base station antenna cover, and the base station antenna cover is made of the above high temperature resistant material.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com