Method for synthetic slag washing of tundish

A tundish and synthetic slag technology, which is applied in the fields of tundish synthetic slag washing and molten steel purification, can solve the problems that inclusions cannot be effectively controlled, it is not conducive to the transformation of one machine and multi-stream continuous casting machine, and it affects the use effect, so as to achieve perfect metallurgy Functional, reduced clogging, enhanced efficiency and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

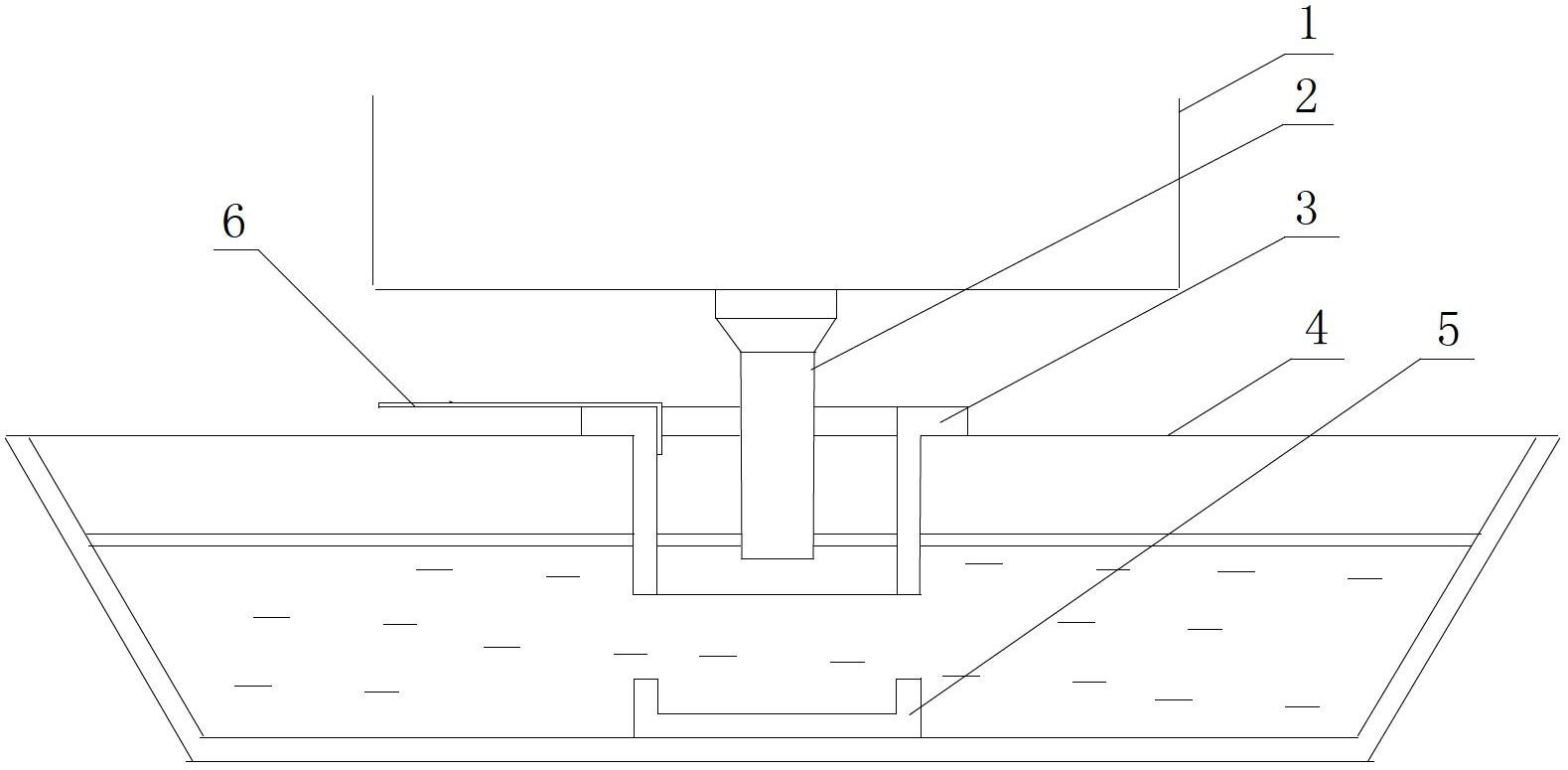

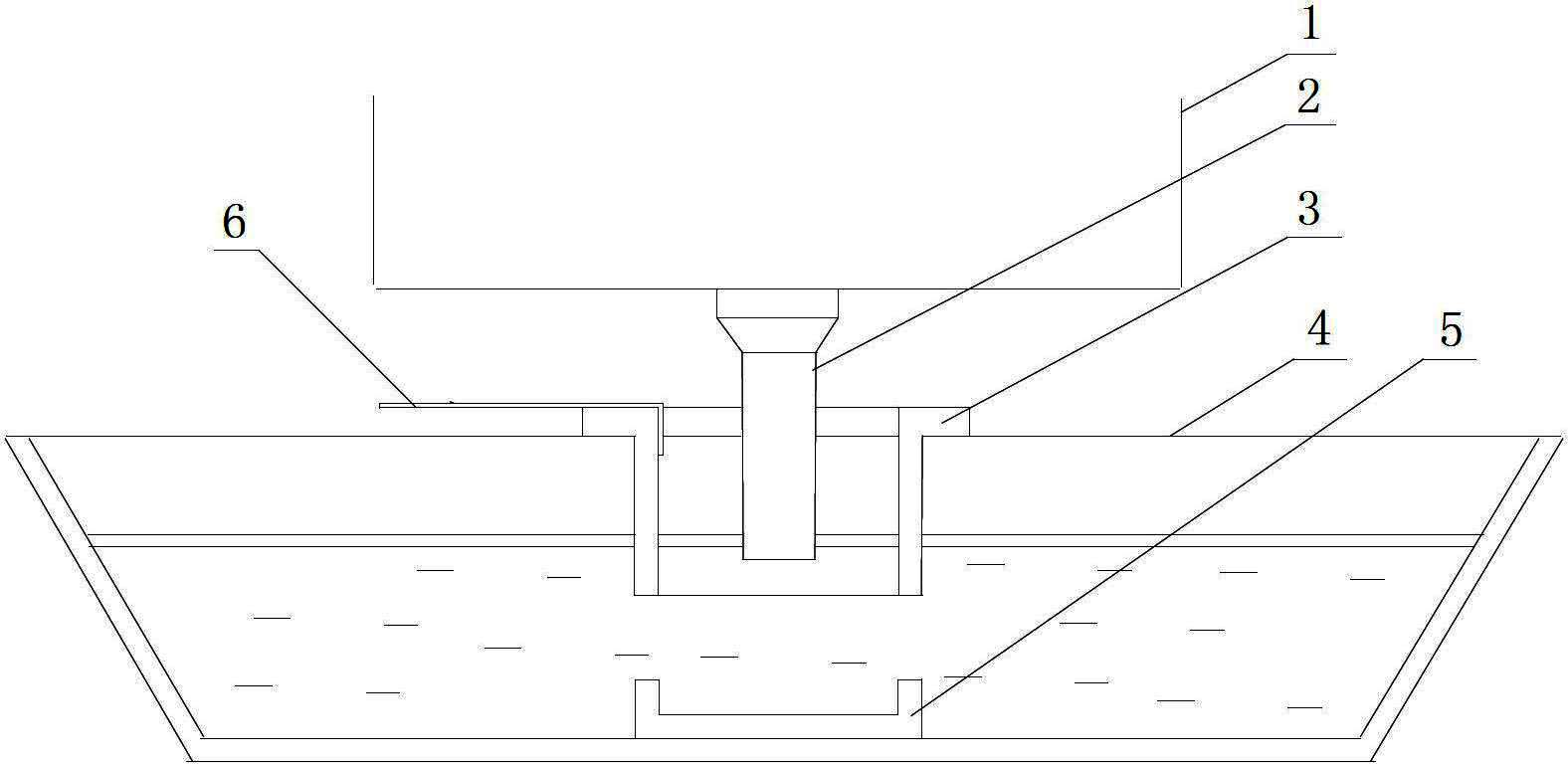

[0025] The concrete steps of the method for tundish synthetic slag washing are:

[0026] 1. Make slag washing pipe 3: use Al-C refractory material to make a slag washing pipe 3 with a small upper opening and a large lower opening by hot isostatic pressing. The upper end of the slag washing pipe 3 cylindrical pipe body is provided with a circle The outer turning edge has an argon blowing hole on the turning edge.

[0027] At the same time, pre-melted slag is prepared. Its main components and weight percent content are:

[0028] CaO 40%, Al 2 o 3 30%, SiO 2 10%, MgO 3%, CaF 2 15%;

[0029] The melting point is 1450°C.

[0030] 2. Before the pouring of the large tank 1, place the edge of the prepared slag washing pipe 3 on the middle hole of the cover of the tundish 4, so that the lower part of the slag washing pipe 3 extends into the tundish 4, and the slag washing The pipe 3 is immersed in molten steel to a depth of 100 mm, and the distance between the lower end of t...

Embodiment 2

[0038] The concrete steps of the method for tundish synthetic slag washing are:

[0039] 1. Making slag washing pipe 3: using Mg-Cr refractory material, a slag washing pipe 3 with a small upper opening and a large lower opening is made by hot isostatic pressing. The outward turning edge has an argon blowing hole on the turning edge.

[0040] At the same time, pre-melted slag is prepared. Its main components and weight percent content are:

[0041] CaO 48%, Al 2 o 3 17%, SiO 2 5%, MgO 8%, CaF 2 18%;

[0042] The melting point is 1200°C.

[0043] 2. Before the pouring of the large tank 1, place the edge of the prepared slag washing pipe 3 on the middle hole of the cover of the tundish 4, so that the lower part of the slag washing pipe 3 extends into the tundish 4, and the slag washing The depth of immersion of the pipe 3 into the molten steel is 300 mm, and the distance between the lower end of the slag washing pipe 3 and the upper surface of the turbulence device at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com