Film coating method for electronic circuit board

An electronic circuit board and coating technology, which is applied in the field of electronic circuit board coating, can solve the problems of incompleteness and uneven coating, and achieve the effects of perfect waterproof, low processing cost, and uniform and complete coating layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

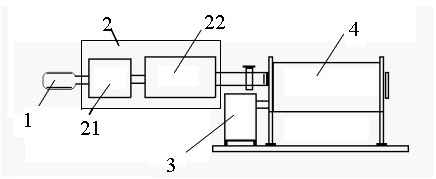

[0034] Such as figure 1 Shown is the used system diagram of the coating process of the present invention, which includes a storage container 1, vaporization chamber 2, cracking chamber 3, condensation equipment 4 and vacuum coating chamber 5 of the coating material p-xylene polymer connected in sequence.

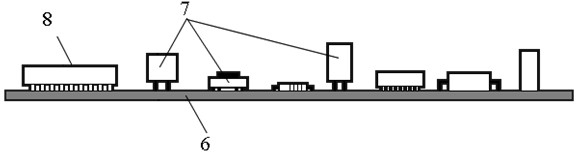

[0035] Such as figure 2 Shown is a schematic diagram of the electronic circuit board after coating in this embodiment, which includes a PCB 6 , components 7 arranged on the PCB 6 and a coating 8 on the surface.

[0036] Preprocessing:

[0037] For the part of the electronic circuit board that does not need coating (that is, it needs to be exposed, and it will be connected with other components to make contacts, transmit signals, etc.) in the future, it must be coated with solder resist. There are parts or devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com