Machining method for forming microstructure on surface of workpiece and control system

A technology of workpiece surface and processing method, which is applied in the field of processing and control systems for forming microstructures on the workpiece surface, can solve the problems of low quality of the processed surface, difficult localization, low processing efficiency, etc., so as to improve the coupling rate and improve the processing efficiency. Efficiency and process stability, the effect of ease of flexible fabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

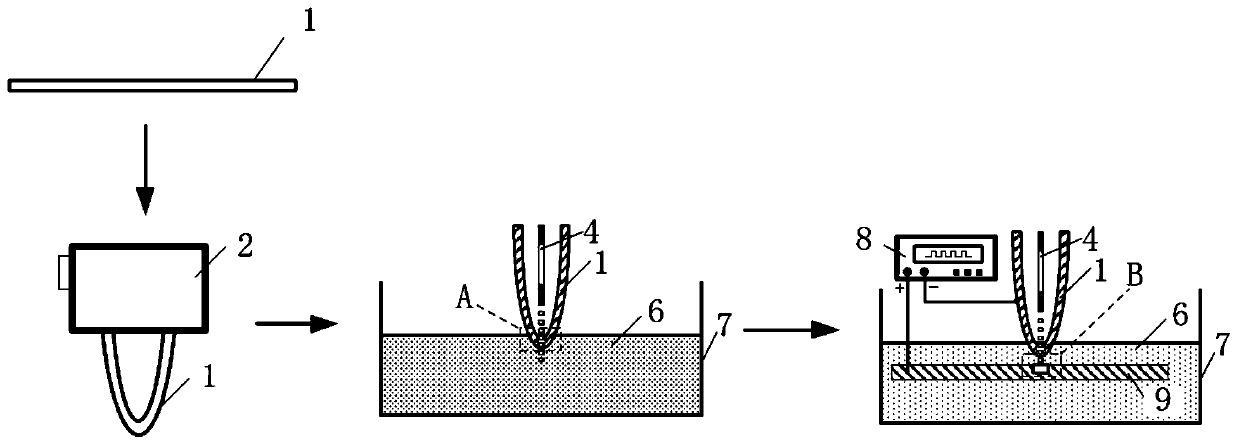

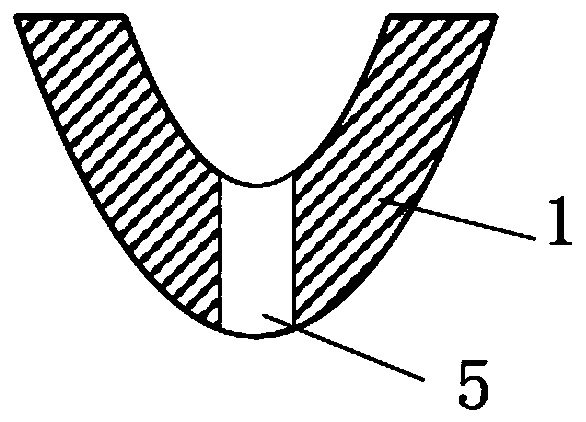

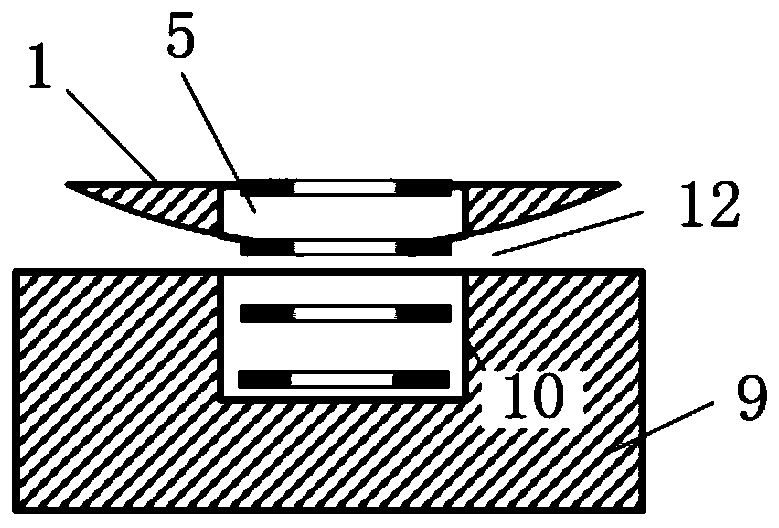

[0043] Step 1, see Figure 1 to Figure 3 , a molybdenum thin plate 1 with a thickness of 50 μm is installed as a cathode 1 in a non-conductive cathode fixture 2 made of plexiglass material. After installation, the molybdenum thin plate 1 will have a certain curvature and form a small curvature surface at the bottom; Cathode 1 and cathode holder 2 were ultrasonically cleaned in alcohol and deionized water for 5 minutes respectively to remove oil and other impurities on the surface of cathode 1 and cathode holder 2, and then the remaining deionized water on the surface of cathode 1 was dried with natural wind. The purpose of bending and fixing the molybdenum thin plate 1 is to make the area of the cathode entering the electrolyte small enough, so as to effectively improve the coupling rate of the laser energy field and the electrochemical energy field in the subsequent laser-electrolysis composite processing process.

[0044] Step 2, see Image 6 , the cathode fixture 2 is fi...

Embodiment 2

[0047] Step 1, see Figure 4 , a tungsten wire 1 with a diameter of 50 μm is used as a cathode 1 and installed in a non-conductive cathode fixture 2 made of organic glass material with a certain tension force, wherein the tension force is 1.0N; the cathode 1 and the cathode fixture 2 Washing and drying, this operation is the same as Step 1 in Example 1, and will not be repeated here.

[0048] Step 2. This step in this embodiment is basically the same as that in Embodiment 1. The control system used is the same control system as that in Embodiment 1. Please refer to Figure 7 , the difference is: the cathode fixture 2 with tungsten wire 1 is fixed on the first three-dimensional precision motion platform 13 in the control system; the tungsten sheet 3 with a thickness of 50 μm is installed in the workpiece fixture 11, and it is fixed on the The second three-dimensional mobile platform 21, then the second three-dimensional mobile platform 21 adjusts it to such as Figure 7 In th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com