Rubber anti-aging paint, and preparation method and application thereof

An anti-aging coating and rubber technology, which is applied to epoxy resin coatings, coatings, and devices for coating liquid on the surface, etc., can solve the problems of cumbersome preparation methods, environmental pollution, and organic solvent pollution, and achieve simple and convenient operation , reasonable cost and obvious improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

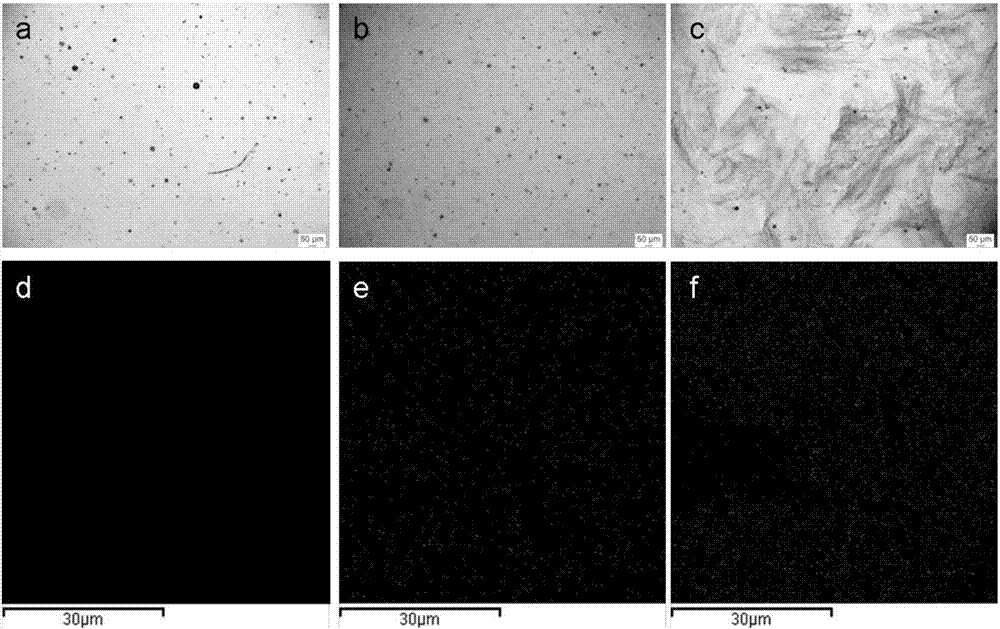

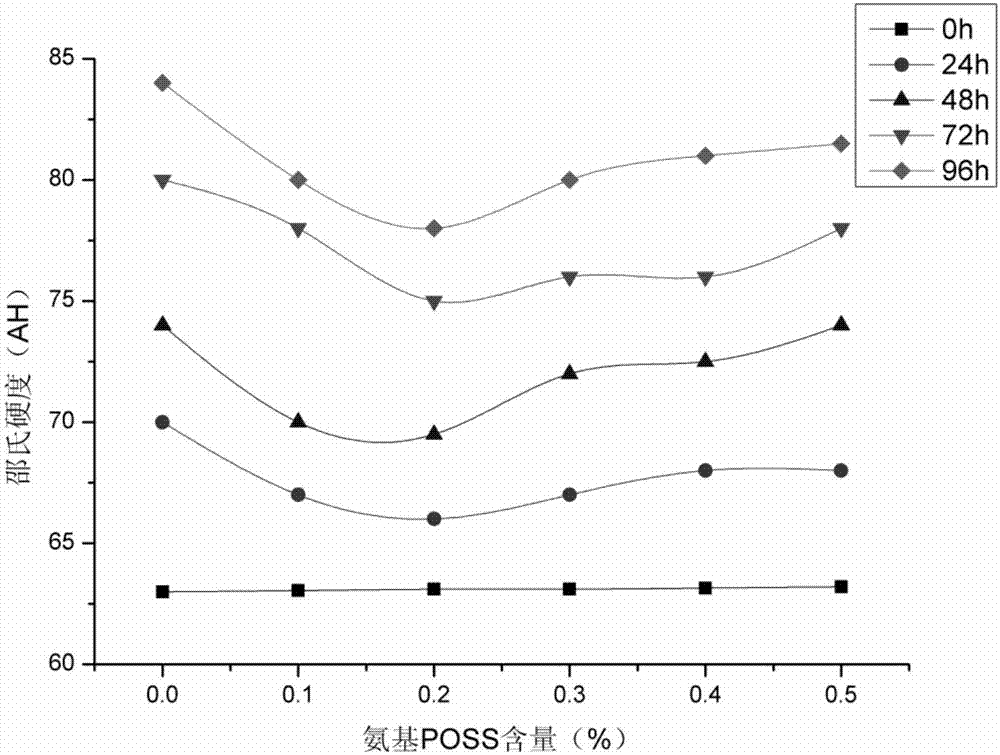

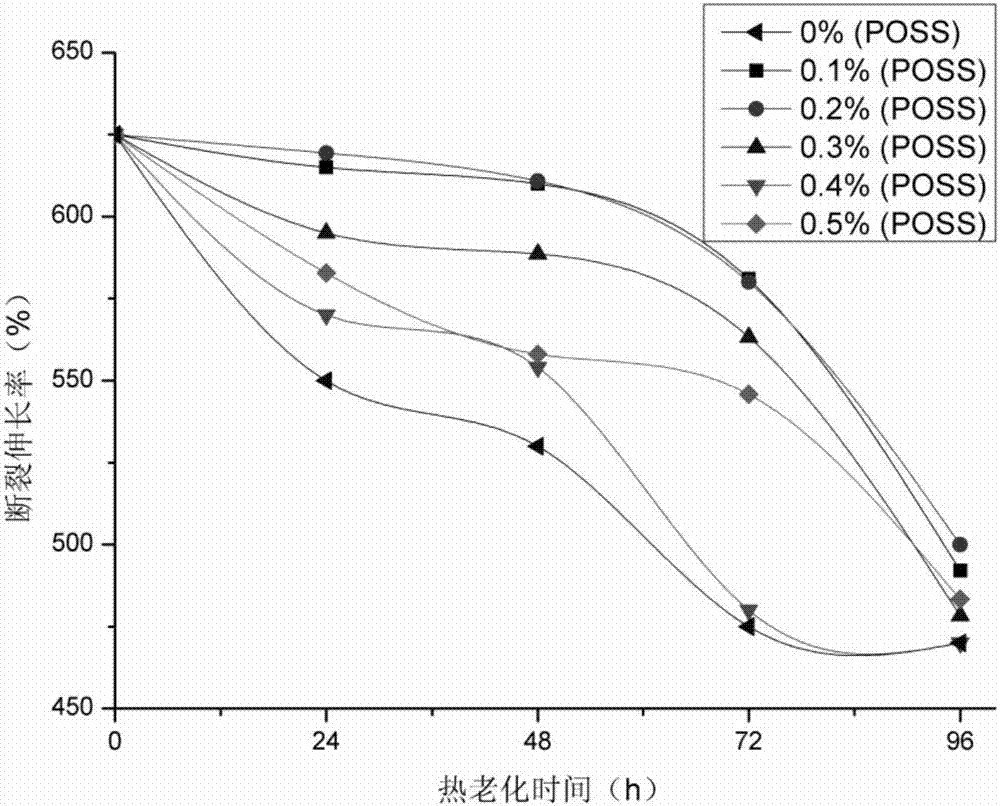

Embodiment 1

[0029] The total weight is 1000 parts, add 200 parts of epoxy resin, 1 part of diethyl phthalate and 1 part of bentonite into a reaction vessel containing 598 parts of deionized water, dissolve until there is no obvious block or flake in the system Materials, and finally obtain a uniform emulsion, which is recorded as liquid A; 0.2 parts of isobutylpropylamino-POSS is dissolved in 197.8 parts of deionized water, which is recorded as liquid B. Add liquid B to liquid A dropwise, and ultrasonicate for 10 minutes while adding; then at 80°C, use a 2mm film applicator to evenly coat the paint on the surface of nitrile rubber, and finally transfer the rubber to a 100°C constant temperature drum In an air drying oven, cure and keep warm for 24 hours.

Embodiment 2

[0031] The total weight is 1000 parts, add 200 parts of epoxy resin, 1 part of diethyl phthalate and 1 part of bentonite into a reaction vessel containing 598 parts of deionized water, dissolve until there is no obvious block or flake in the system materials, and finally obtain a uniform emulsion, which is recorded as liquid A; 0.4 parts of isobutylpropylamino-POSS are dissolved in 197.6 parts of deionized water, which is recorded as liquid B. Add liquid B to liquid A dropwise, and ultrasonicate for 10 minutes while adding; then at 80°C, use a 2mm film applicator to evenly coat the paint on the surface of nitrile rubber, and finally transfer the rubber to a 100°C constant temperature drum In an air drying oven, cure and keep warm for 24 hours.

Embodiment 3

[0033]The total weight is 1000 parts, add 200 parts of epoxy resin, 1 part of diethyl phthalate and 1 part of bentonite into a reaction vessel containing 598 parts of deionized water, dissolve until there is no obvious block or flake in the system Materials, and finally obtain a uniform emulsion, which is recorded as liquid A; 0.6 parts of isobutylpropylamino-POSS is dissolved in 197.4 parts of deionized water, which is recorded as liquid B. Add liquid B to liquid A dropwise, and ultrasonicate for 10 minutes while adding; then at 80°C, use a 2mm film applicator to evenly coat the paint on the surface of nitrile rubber, and finally transfer the rubber to a 100°C constant temperature drum In an air drying oven, cure and keep warm for 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com