Die-bonding film and use thereof

A die-bonding film and acrylic technology, which can be applied in the direction of film/sheet without carrier, film/sheet-shaped adhesive, thin material processing, etc., and can solve the problem that the slurry adhesive layer is difficult to homogenize, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

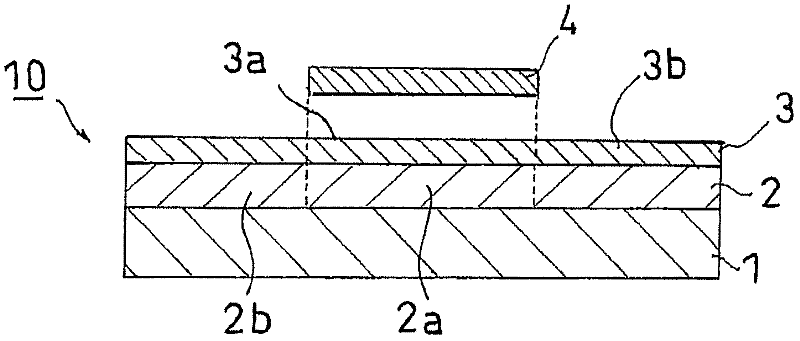

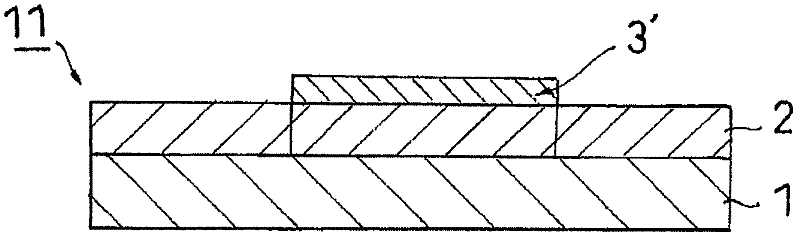

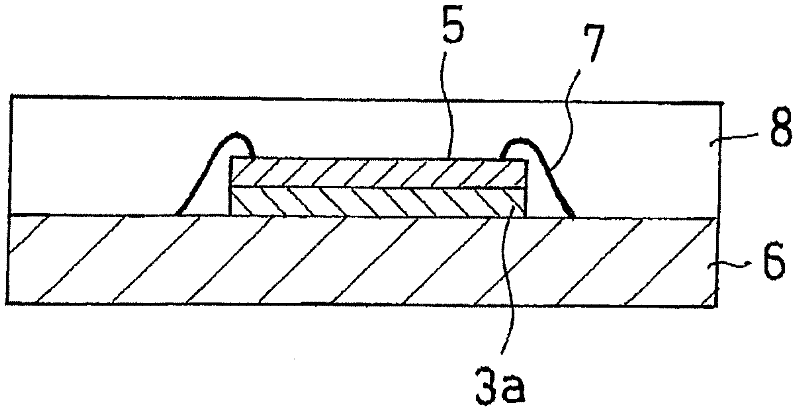

Image

Examples

Embodiment 1

[0152] The glycidyl group-containing acrylic copolymer (a) mainly composed of acrylonitrile-ethyl acrylate-butyl acrylate had an epoxy value of 0.18, a glass transition point (Tg) of 30°C, and a weight-average molecular weight of 100 parts of 1.1 million acrylate polymer (manufactured by Negami Industry Co., Ltd., glycidyl acrylate 1.9 mol%) and 17.5 parts of phenolic resin (manufactured by Meiwa Chemical Industry Co., Ltd., "MEH7851") as the phenolic resin (b) were dissolved in In methyl ethyl ketone, an adhesive composition having a concentration of 23.6% by weight was prepared.

[0153] This adhesive composition was coated on a release-treated film as a release liner composed of a polyethylene terephthalate film having a thickness of 50 μm after a silicone release treatment, and then dried at 130° C. for 2 minute. Thus, a die-bonding film having a thickness of 25 μm was produced.

Embodiment 2

[0155] The glycidyl group-containing acrylic copolymer (a) mainly composed of acrylonitrile-ethyl acrylate-butyl acrylate had an epoxy value of 0.22, a glass transition point (Tg) of 15°C, and a weight-average molecular weight of 100 parts of 800,000 acrylate polymer (manufactured by Negami Industry Co., Ltd., glycidyl acrylate 2.3 mol%) and 12.5 parts of phenolic resin (manufactured by Meiwa Chemical Industry Co., Ltd., "MEH7851") as the phenolic resin (b) were dissolved in In methyl ethyl ketone, 40 parts of spherical silica (manufactured by Admatex Co., Ltd., "SO-25R") with an average particle diameter of 500 nm was dispersed therein to prepare an adhesive composition having a concentration of 23.6% by weight. Except for this, it carried out similarly to Example 1, and produced the die-bonding film.

Embodiment 3

[0157] The glycidyl group-containing acrylic copolymer (a) mainly composed of acrylonitrile-ethyl acrylate-butyl acrylate had an epoxy value of 0.42, a glass transition point (Tg) of 15°C, and a weight-average molecular weight of 100 parts of 800,000 acrylate polymer (manufactured by Negami Industry Co., Ltd., glycidyl acrylate 4.5 mol%) and 6.5 parts of phenolic resin (manufactured by Meiwa Chemical Industry Co., Ltd., "MEH7851") as the phenolic resin (b) were dissolved in In methyl ethyl ketone, 40 parts of spherical silica (manufactured by Admatex Co., Ltd., "SO-25R") with an average particle diameter of 500 nm was dispersed therein to prepare an adhesive composition having a concentration of 23.6% by weight. Except for this, it carried out similarly to Example 1, and produced the die-bonding film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com