Plastic anchor floater

An anchor float and plastic technology, which is used in special purpose ships, ships, buoys, etc., can solve the problems of steel anchor float, easy corrosion of steel plates, large size, etc., to improve impact resistance, prolong service life, and float. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

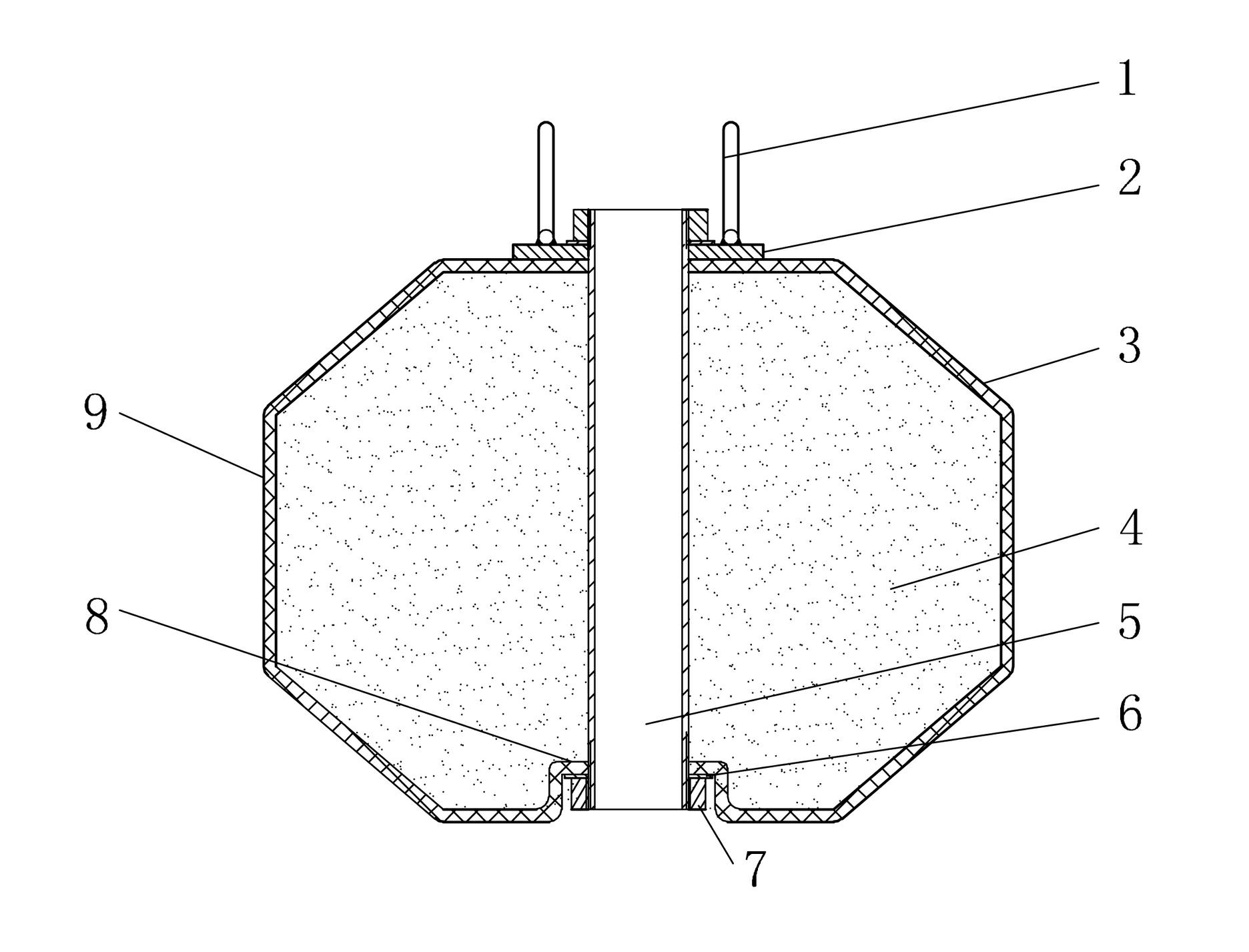

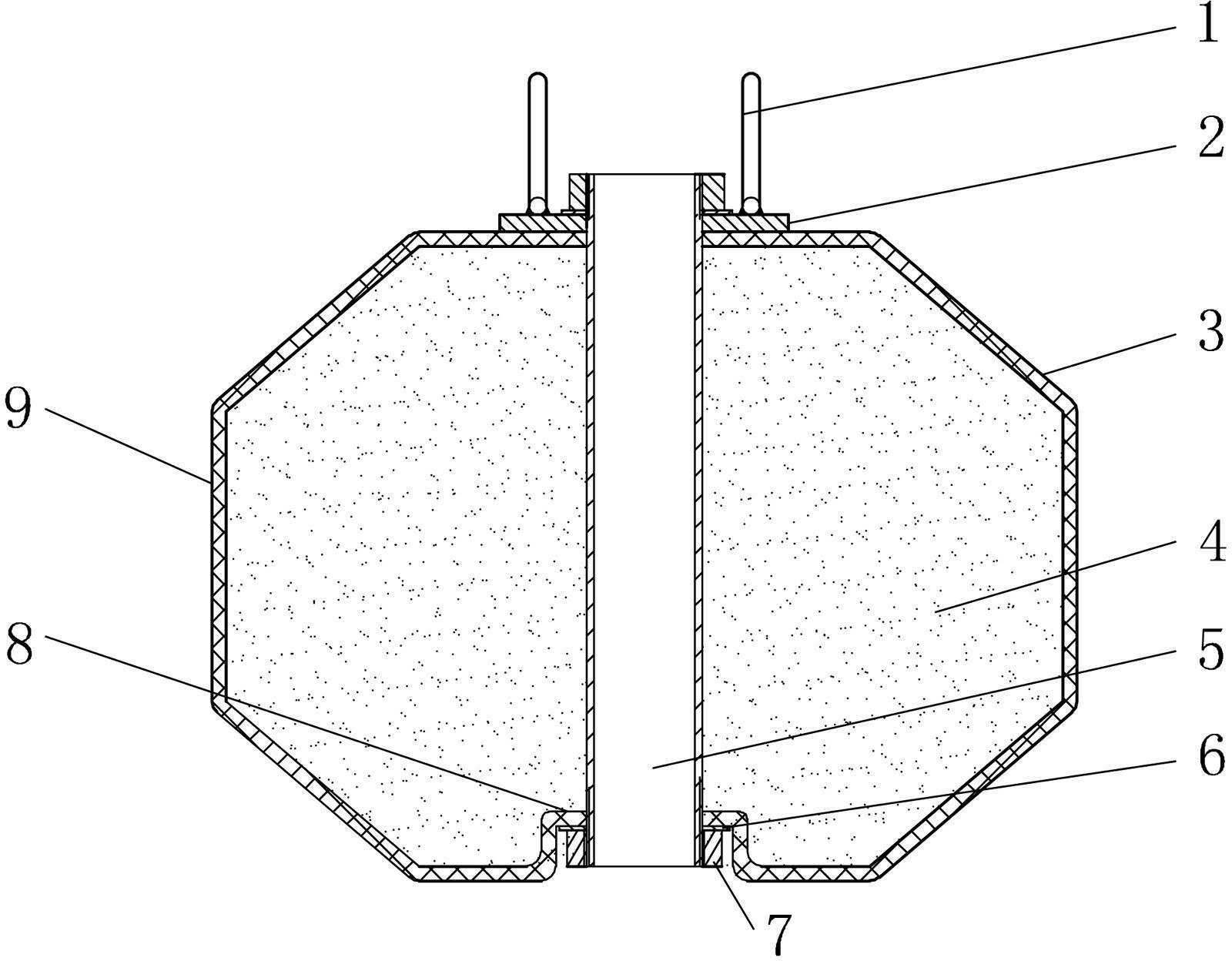

[0009] As shown in the figure: Change the steel shell of the anchor float 8 to a plastic shell 3, the shell 3 is equipped with a foam 4, the foam 4 is foam plastic, a steel pipe 5 is set in the center of the anchor float 8, and the steel pipe 5 uses a nut 7 , The flat pad 6 is connected to the clamping board 8 at the bottom of the anchor float 8. The clamping board 8 has a corner structure. A gland 2 is arranged on the top of the anchor drift 8, and two lifting rings 1 are arranged on the gland 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com