Durable wood-bamboo cellulose composite material

A bamboo cellulose and composite material technology, which is applied to wood processing appliances, household components, flat products, etc., can solve the problems of wood bamboo fiber or plant fiber being easy to grow fungi and high price, and achieve long service life and shock resistance. Strong, low-emission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

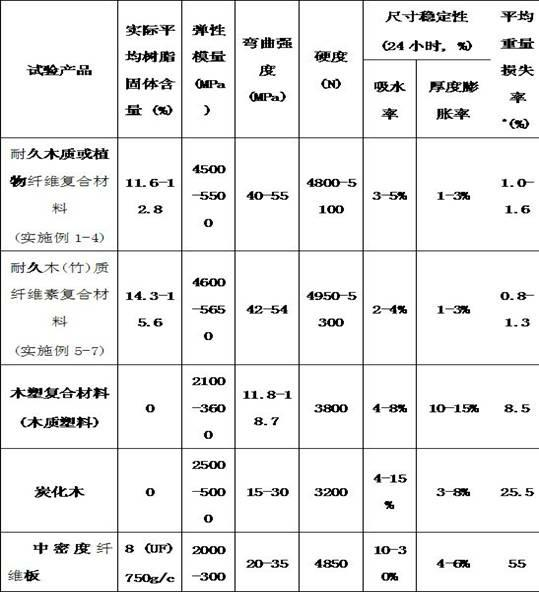

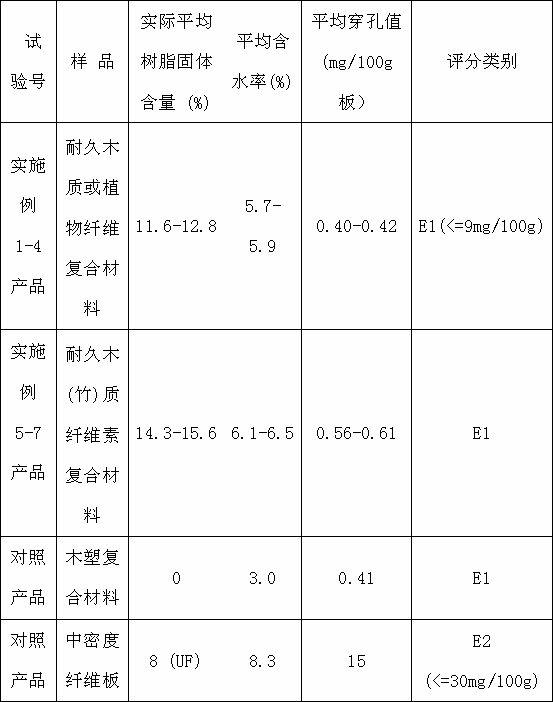

Examples

Embodiment 1

[0024] The material is 9 mm thick low-density wood fiberboard (density 350kg / m 3 About), using low molecular weight modified phenolic resin and additives treatment method. Phenolic resin molecular weight 200, viscosity 100-250cps at 25°C, solid resin content 50%-60%, and modified by diphenylmethane diisocyanate (MDI) (application amount 3%) to increase water resistance; additive is borax , boric acid, potassium borate and sodium carbonate, the ratio (weight) can be 1: 1: 1: 2, and the dosage can be up to 5% of the resin weight to reduce the osmotic pressure of wood and increase the pH value of the product surface. The wood fiber board can be treated in the modified phenolic resin glue for 5 minutes by dipping method, or the modified phenolic resin glue can be rolled directly on the wood fiber board to replace the traditional vacuum-pressurization and other treatment methods. After sizing, the average phenolic solid resin content of the wood fiber board reaches 12%. After the...

Embodiment 2

[0026] The difference from Example 1 is that three-layer or five-layer wood fiber boards are assembled, and then heated and pressed by microwave (or radio frequency), the hot-pressing pressure is 1.5-2.0 MPa, the hot-pressing temperature is 90-105 degrees, and the hot-pressing time is about 5-10 minutes, the pH value of the product surface is between 10 and 12. The product has good corrosion resistance, no need for anti-corrosion treatment, enough for outdoor use.

Embodiment 3

[0028] The material is a low-density plant fiber board made of 9mm thick diphenylmethane diisocyanate MDI (density 350 kg / m 3 About), other with embodiment 1. Use the method of impregnating the modified phenolic resin to treat the plant fiber board for 5-30 minutes, or directly roll-coat the modified phenolic resin glue to replace the traditional vacuum-pressure treatment. After sizing, the 9 mm thick plant fiber board is evenly The content of phenolic solid resin reaches 12%. After the above treatment, the three-layer or five-layer plant fiber plate assembly is hot-pressed, the hot-pressing pressure is 1.5-3.0 MPa, the hot-pressing temperature is 145-155C°, the hot-pressing time is about 8-20 minutes, and the pH value of the product surface is 10 and 12. The product has good corrosion resistance, no need for anti-corrosion treatment, enough for outdoor use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com