Head of long-head mine vehicle

A technology for mining vehicles and fronts, which is applied to vehicle components, vehicle safety arrangements, and the upper structure of trucks, etc. It can solve the problems of affecting the filtering effect, excessive dust in the fog machine, and insufficient air intake, etc., and achieves the shock resistance. Poor, less impact effect, strong shock resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

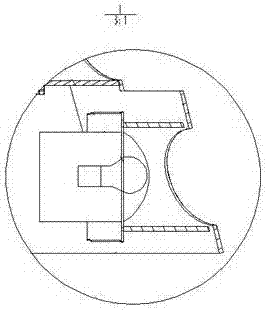

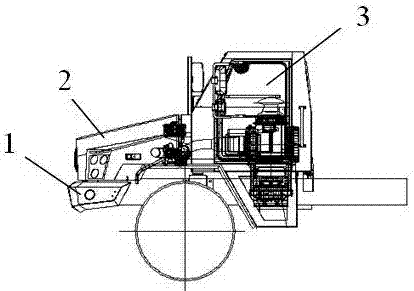

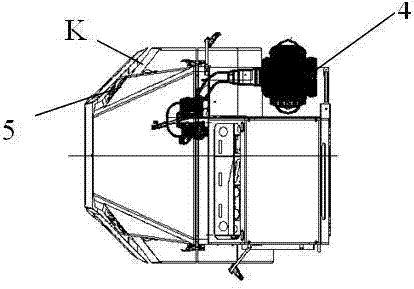

[0036] Such as figure 1 , 2 As shown, the front turning assembly 2 adopts an integral forward turning method, adopts the overall forward turning method, and uses a gas spring for the forward turning and turning. Figure 17 , 18 , 19, and 20, the skeleton form is adopted, and the outer surface is welded with sheet metal, such as image 3 , 4 , 5, and 6 show that the structure is firm and has a strong anti-collision function; figure 1 , 2 , 3, 4, 5, and 6, the cab 3 is a leftward offset structure, so that a platform is formed on the right side of the cab, and an air filter assembly 4 is installed on the right side of the cab. 4 Adopt super-high-power desert air filter to effectively filter intake impurities, and at the same time meet the air intake requirements of underground tunnels with thin air; solve the problem of no space for installing large air filters on old models, because the use of super-large air filters perfectly solves the problem It solves the problem that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com