High-chromium alloy wear-resistant steel ball and processing method thereof

A technology of high chromium alloy and processing method, which is applied in the direction of building components, springs/shock absorbers, vibration suppression adjustment, etc., can solve the problems of broken balls, reduced use effect of steel balls, low frictional connection, etc., to improve the use of effect, the effect of enhancing the frictional connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

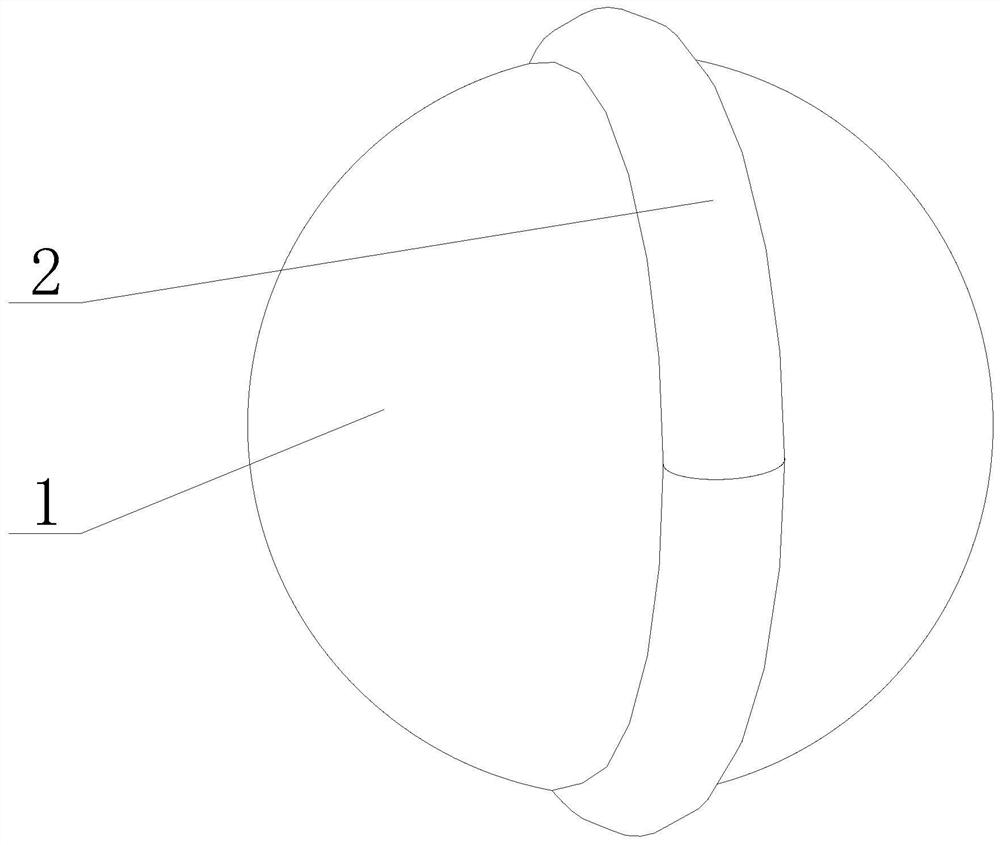

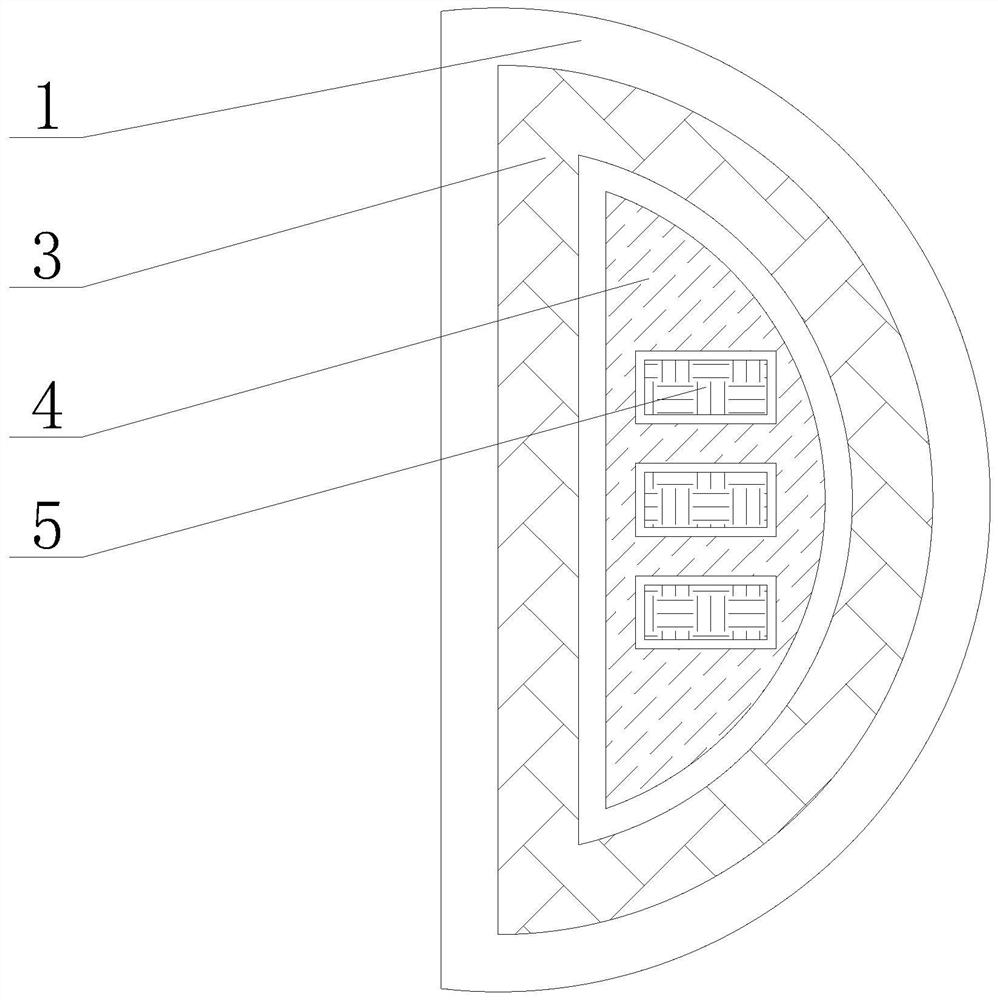

[0039] Such as figure 1 - Figure 5 As shown, the present invention provides a high chromium alloy wear-resistant steel ball and a processing method thereof, comprising a wear-resistant steel ball main body 1, an outer friction semi-arc ring 2 is arranged on the surface of the wear-resistant steel ball main body 1, and an outer friction half arc ring 2 is arranged on the surface of the wear-resistant steel ball main body 1. The arc ring 2 is used to enhance the friction connection with the object. The wear-resistant steel ball main body 1 is provided with an oscillation offset shaft 5. The oscillation offset shaft 5 is used to reduce the impact force inside the ball. The outer friction half arc ring The inner side of 2 is fixedly installed on the surface of the wear-resistant steel ball main body 1, and the outer friction semi-arc ring 2 can increase the friction between the outer surface of the wear-resistant steel ball main body 1 and the object, and the inner wall of the we...

Embodiment 2

[0041] Such as Figure 1-5As shown, on the basis of Embodiment 1, the present invention provides a technical solution: an oscillation conduction platform 7 is provided inside the vibration canceling shaft 5 and inside the shock-transmitting heat-resistant frame 9, and the outside of the oscillation conduction platform 7 is fixedly installed In the inner side of the shock-transmitting heat-resistant frame 9, and the inner side of the vibration conduction platform 7 is provided with a heat-resistant shock-absorbing spring 8, and the vibration-conducting platform 7 can conduct the vibration that the sphere produces after being hit to the heat-resistant shock-absorbing spring 8, so that The heat-resistant shock-absorbing spring 8 reduces the impact force inside the sphere, the outer side of the heat-resistant shock-absorbing spring 8 is fixedly installed on the inner side of the vibration conduction platform 7, and the inner wall of the outer friction half-arc ring 2 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com