Coating damping cutter rod and damping testing method thereof

A tool holder and damping technology, which is applied in the field of cutting tools, can solve problems such as unsatisfactory processing conditions, poor vibration damping effect and adaptability, and complex structure, so as to improve machining accuracy and efficiency, suppress vibration, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: Taking the boring bar with obvious self-excited vibration in the machining process as an example, a coated damping and vibration-absorbing boring bar is designed. The coating method is cylindrical boring bar 3 outer coating 1. The hollow boring bar 3 has an aspect ratio of 6:1, an outer diameter of φ30mm, and an inner diameter of φ20mm. The base material is 40Cr alloy structural steel, and its elastic modulus E s =200GPa, loss factor η s =0.0001, damping ratio ζ s =0.015; the outer coating damping material is M2052 alloy, the modulus of elasticity E c =50GPa, loss factor η c =0.23, coating thickness H c =0.1mm.

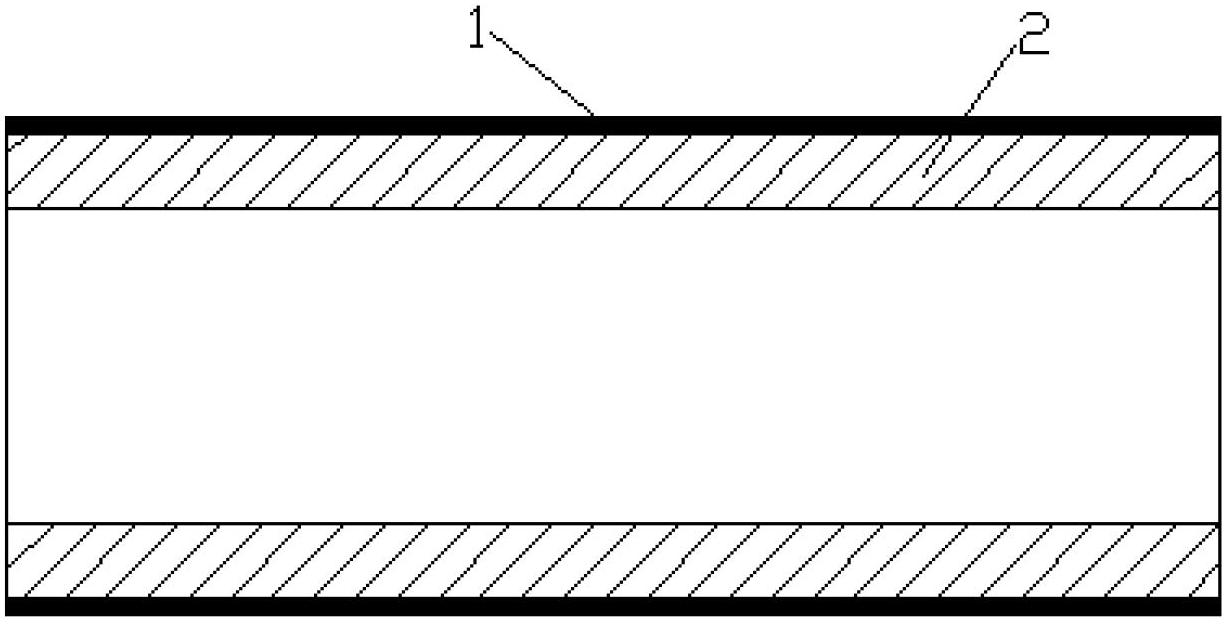

[0042] Such as Figure 5 In the cross-sectional structure of the outer coating 1 of the boring bar 3 shown, the overall loss factor η of the coating damping and damping boring bar is calculated according to the following formula:

[0043] η = ( E ...

Embodiment 2

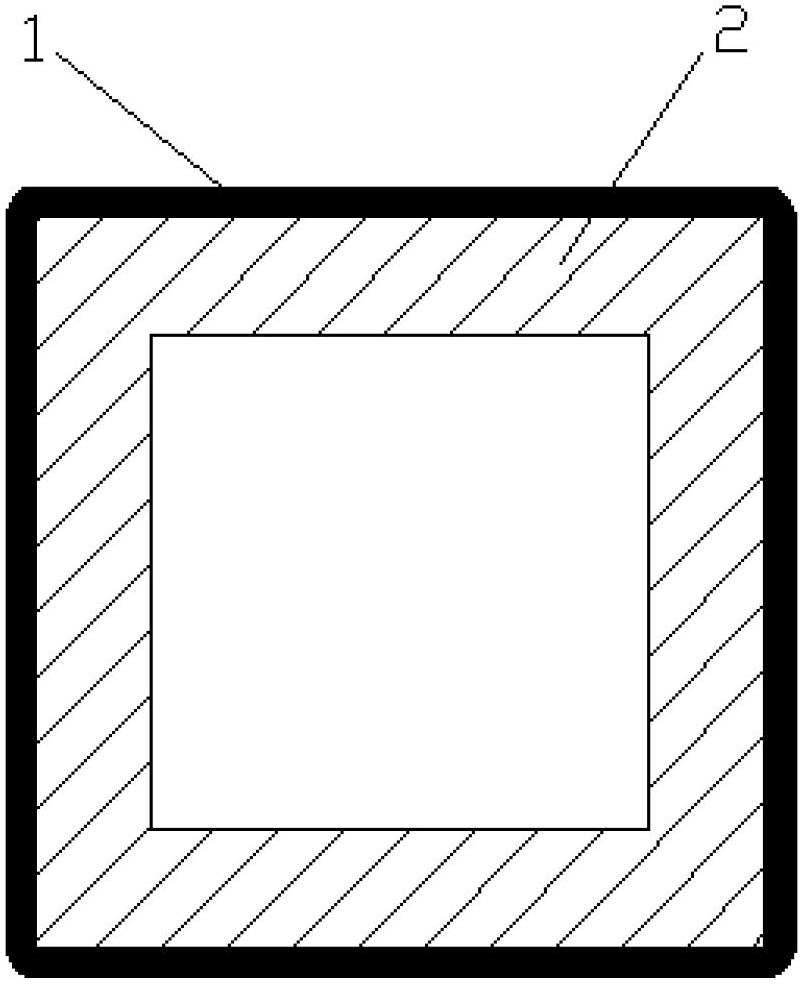

[0048] Embodiment 2: According to image 3 Design a coating damping and vibration reduction turning tool holder. The coating thickness H of the inner wall of the turning tool holder is applied by thermal spraying process c =0.15mm Ni-Ti alloy, improve the damping characteristics of the turning tool holder, so as to achieve the purpose of reducing vibration. The base material of the tool holder is 40Cr alloy structural steel, and the loss factor η s =0.0001; coating damping material is Ni-Ti alloy, loss factor η c =0.18, coating thickness H c =0.15mm. The vibration-damping turning tool holder is mainly used for vibration reduction and noise reduction of the turning tool holder in the machining process.

Embodiment 3

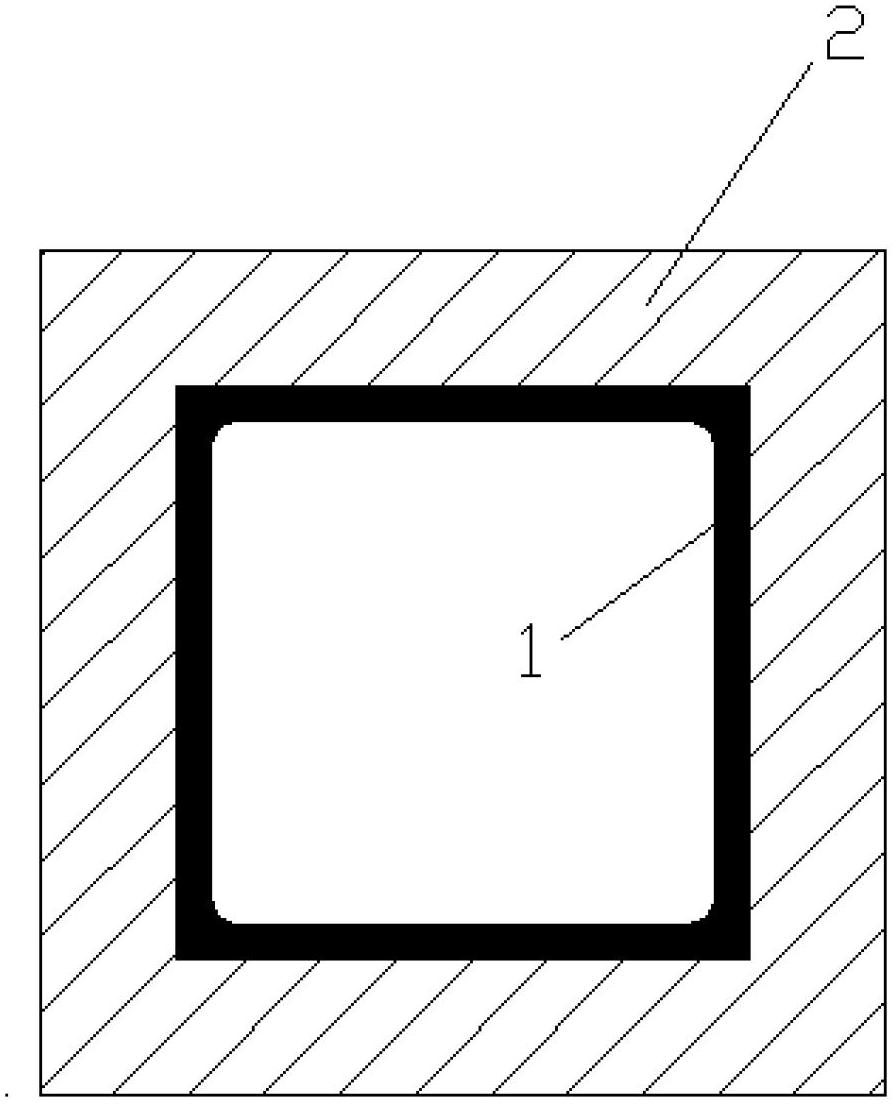

[0049] Embodiment 3: according to Image 6 A coated damping and vibration-absorbing milling cutter bar is designed as shown. Coating thickness H on the periphery of the milling cutter shank c =0.1mm Fe-Cr alloy. Fe-Cr alloy is a high damping alloy material with strong vibration damping ability, which can improve the vibration resistance of the milling cutter shaft. The base material of the tool holder is hard alloy. The vibration-damping tool holder is mainly used for vibration and noise reduction of the milling tool holder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter φ | aaaaa | aaaaa |

| Inner diameter φ | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com