Locking, cooling and lubricating hydraulic system of heavy hydraulic automatic transmission

An automatic transmission, cooling and lubrication technology, applied in the direction of gear lubrication/cooling, transmission, components with teeth, etc. Solve problems such as the reduction of oil volume in the torque converter to the lubricating oil circuit, and achieve the effect of enhancing R&D capabilities, making full use of oil, and suppressing shock and vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The locking and cooling lubricating hydraulic system of the heavy-duty hydraulic automatic transmission provided by the present invention will be described in detail below in conjunction with the accompanying drawings. It is an optional embodiment of the present invention. It can be considered that those skilled in the art will not change the It can be modified and polished within the scope of the spirit and content of the invention.

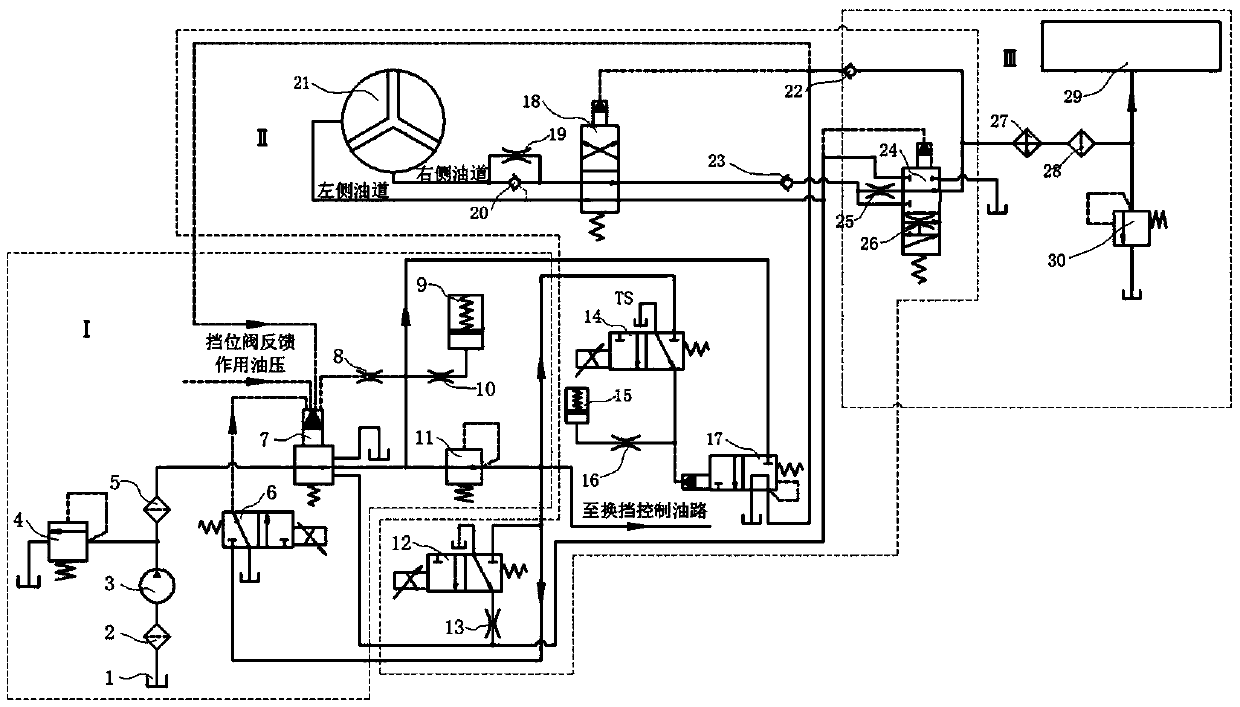

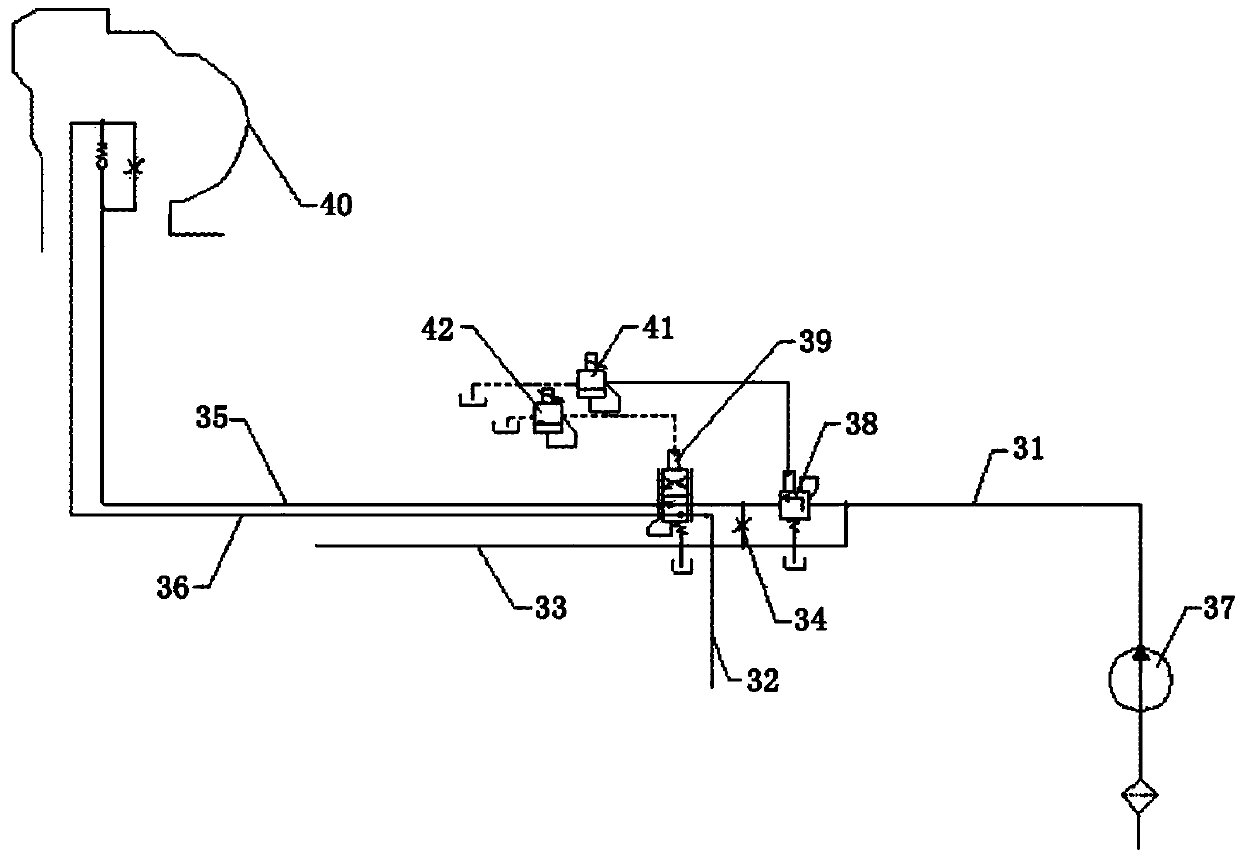

[0020] Such as figure 1 As shown, the locking and cooling and lubricating hydraulic system of the heavy-duty hydraulic automatic transmission of the present invention is composed of three parts: the main pressure regulating system, the torque converter locking control system and the cooling and lubricating system. The working principles of these three parts are introduced respectively below.

[0021] The main function of the main pressure regulating system of the heavy-duty hydraulic automatic transmission is to automatically adjust acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com