Preparation method for copper-steel composite

A composite material and copper plate technology, which is applied in metal material coating process, metal rolling, coating, etc., can solve the problems of large plate-shaped parts that are difficult to be uniformly combined, coarse structure, interface corrosion, etc., and achieve small reduction , Low composite temperature, little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Through the conventional hot-dip galvanizing method, degrease, derust, dip in the plating solution, and dry the surfaces of the steel plate and copper plate to be laminated, and dip a layer of zinc with a thickness of 10 μm in the zinc solution at 450 ° C. Spray water-based graphite paint on the non-dipping surface and dry it for protection; heat the galvanized steel plate and copper plate galvanized surface to 450°C under the protection of static hydrogenation nitrogen containing 0.2 vol.% hydrogen, keep it warm for 10 minutes, and then In the case of a reduction of 5%, the copper-steel composite material was obtained by rolling through two rolls successively, and holding time at 550°C for 2.0h.

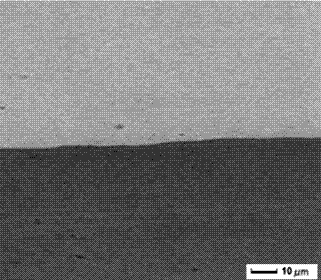

[0020] figure 1 For photos of copper-steel composites, figure 2 It is an SEM photo of the copper-steel composite interface; it can be seen from the figure that the copper-steel interface is well bonded, and the test of the interface bonding strength shows that the tensile s...

Embodiment 2

[0022] Through the conventional hot-dip galvanizing method, degrease the surface of the steel plate and copper plate to be laminated, derust, dip in the plating solution, dry, and dip-coat in a zinc-aluminum alloy (Zn-5wt%) melt at 440 ° C for a period of time. For zinc-aluminum alloys with a layer thickness of 8 μm, spray water-based graphite coating on the non-dip-coated surface before immersion plating and dry it for protection; Heated to 500°C under the protection of hydrogenation and nitrogen, and held for 8 minutes, and then rolled through two rolls successively at a reduction of 5%, and held at 550°C for 1.5 hours to obtain a copper-steel composite material. Analysis shows that, The copper-steel interface is well bonded, and the tensile strength of the copper-steel composite interface reaches 90MPa.

Embodiment 3

[0024] Through the conventional hot-dip galvanizing method, degrease, derust, dip in the plating solution, and dry the surfaces of the steel plate and copper plate to be laminated, and dip-coat a layer of zinc with a thickness of 3 μm in a zinc melt at 460 ° C. Before dip-plating Spray alcohol-based graphite paint on the non-dipping surface for protection; heat the galvanized steel plate and copper plate galvanized surface to 550°C under the protection of static hydrogenation nitrogen containing 0.5vol.% hydrogen, keep it warm for 5min, and then press the amount In the case of 10%, the copper-steel composite material is obtained by rolling with two rolls successively at 600 ° C for 1.0 h. The analysis shows that the copper-steel interface is well bonded, and the tensile strength of the copper-steel composite interface reaches 95MPa .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com