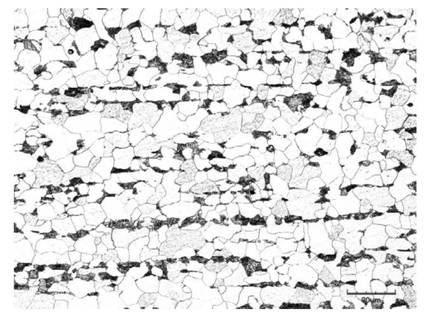

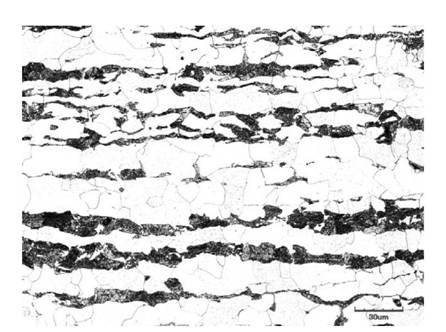

High speed production method for controlling banded structure of low carbon steel wire rod

A production method and banded structure technology, applied in the field of steel rolling, can solve the problems of unfavorable cold heading steel wire rod deep processing and insufficient depth, and achieve the effect of improving material structure uniformity, cold heading ability, and strong process applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

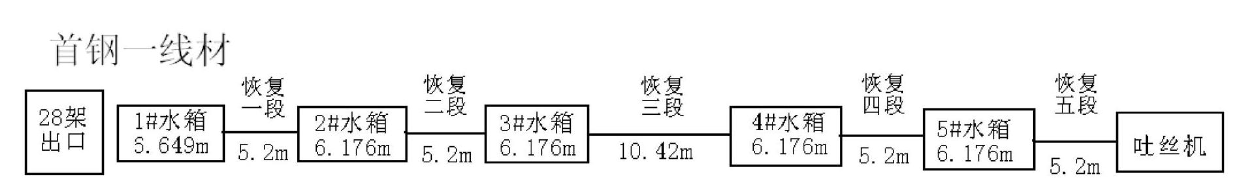

[0029] The present invention is implemented and applied in the 6.5 specification low-carbon cold heading steel 22A developed by Shougang No. 1 Rod Factory. The specific process is as follows:

[0030] a. The steel billet is a continuous casting 160mm square billet, the temperature of the soaking section of the heating furnace is controlled at 1120°C, and the soaking time of the soaking section is 40 minutes to ensure the uniform diffusion of alloying elements;

[0031] b. After 6 passes of rough rolling, the deformation amount is 75%; 6 passes of intermediate rolling, the deformation amount is 82%; 6 passes of pre-finish rolling, the deformation amount is 65%; The temperature is 900°C;

[0032] c. Turn on and strengthen the water cooling guide during the finishing rolling process, and control the temperature rise of the finishing rolling at 100°C;

[0033] d. After rolling, five water-cooled boxes are used for rapid cooling to ensure that the first three water-cooled boxe...

Embodiment 2

[0036] The present invention is implemented and applied in the development of 6.5 specification low-carbon cold heading steel 22A by the high-wire factory of Shougang Shuigang Company. The specific process is as follows:

[0037] a. The steel billet is a continuous casting 150mm square billet, the temperature of the soaking section of the heating furnace is controlled at 1080°C, and the soaking time of the soaking section is 30 minutes to ensure the uniform diffusion of alloying elements;

[0038] b. After 6 passes of rough rolling, the deformation amount is 71%; 6 passes of intermediate rolling, the deformation amount is 82%; 6 passes of pre-finish rolling, the deformation amount is 65%; The temperature is 860°C;

[0039] c. Turn on and strengthen the water cooling guide during the finishing rolling process, and control the temperature rise of the finishing rolling at 120°C;

[0040] d. After rolling, five water cooling boxes are used for rapid cooling to ensure that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com