Composite material used as lithium air battery positive electrode and preparation method thereof

A lithium-air battery and composite material technology, which is applied in battery electrodes, fuel cell-type half-cells and secondary battery-type half-cells, circuits, etc., can solve the problems of poor rechargeable performance and short service life of lithium negative electrodes, etc. To achieve the effect of reducing the charging voltage, increasing the discharge specific capacity, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The method for preparing above-mentioned composite material of the present invention, comprises the following steps:

[0036] 1) According to the mass ratio of porous carbon to sodium hydroxide is 1:6~1:8 or the mass ratio of porous carbon to nitric acid is 1:6~1:12 for material preparation, use 5~10 mol / L nitric acid solution or Activate the porous carbon with 8-10 mol / L sodium hydroxide solution, place the reacted solution in a centrifuge, pour off the supernatant, put the lower layer of black precipitate in a blast drying oven at 50-70 °C Drying for 10 to 12 h under high temperature, the porous carbon with hydrophilic groups on the surface was obtained;

[0037] 2) The molar ratio of raw materials is potassium permanganate: reducing agent: distilled water: porous carbon = 1:1:1:10~1:1:2:20, take potassium permanganate and reducing agent, add distilled water to dissolve it, Add the porous carbon containing hydrophilic groups obtained in the step 1), stir for 10-30 mi...

Embodiment 1

[0050] (1) Preparation of mesoporous carbon

[0051] Self-assembly: Take 1.22 g of phenol and put it in a round bottom flask, heat it to 40~42 °C to make it melt, add 0.26 g of 20wt%~40wt% NaOH solution, add dropwise under stirring, then stir for 10 min, 50 Add 2.10 g of formalin dropwise below °C, then raise the temperature to 75~85 °C and stir for 1 h, cool to room temperature, adjust the pH to 7 with hydrochloric acid, transfer to a rotary evaporator to remove water by vacuum evaporation, and obtain a phenolic resin. It is dissolved in ethanol to prepare 20wt%~40wt% ethanol solution of phenolic resin.

[0052] Condensation: 1.0 g polyoxyethylene-polyoxypropylene-polyoxyethylene triblock polyether (simplified molecular formula EO 106 PO 70 EO 106 , molecular weight is 12600) dissolved in 20.0 g ethanol, add 5 g 20wt%~40wt% ethanol solution of phenolic resin (under stirring, 10~30 min) to get a homogeneous solution, continue stirring for 2 h, transfer to evaporating dish, ...

Embodiment 2

[0064] (1) Adjust the pH of the phenolic resin preparation system to 4, and the reaction temperature is 75 °C. Using the phenolic resin as a carbon source, set the carbonization temperature to 650 °C to prepare mesoporous carbon.

[0065] (2) Activation of mesoporous carbon

[0066] 20 mg of mesoporous carbon was dissolved in 20 mL of 8 mol / L sodium hydroxide solution, stirred at 80 °C for 7 h, then washed with deionized water until neutral, and dried at 70 °C for 12 h.

[0067] (3) Nano α-MnO 2 / mesoporous carbon composite

[0068] Take 2 mmol KMnO 4 , 1 ml of concentrated sulfuric acid, 23 mL of deionized water, and the activated mesoporous carbon in step (2), stirred for 10 min, then placed in an oven, reacted at 140 °C for 24 h, then filtered, and then used After repeated washing with deionized water and absolute ethanol several times, and finally drying at 80 °C for 12 h, composite material 2 was obtained.

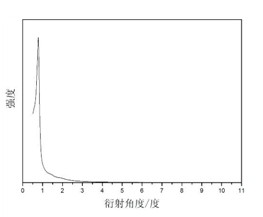

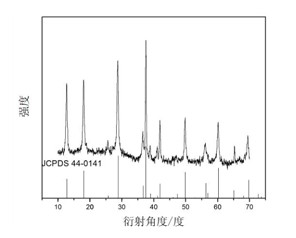

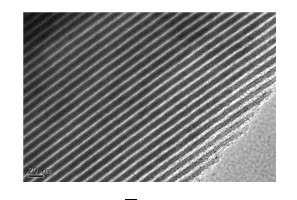

[0069] The phase and structure of the sample were determined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com