Method for preparing composite dopant LiMn2O4 by one-step sintering solid-phase reaction

A technology of compound doping lithium manganate and solid-phase reaction, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as increasing production costs, achieve performance improvement, promote solid-phase reaction, and improve electrochemical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Weigh 715 g of lithium carbonate and 58 g of aluminum hydroxide into a high-speed mixing granulator and mix for 30 minutes.

[0023] (2) Add 44 g of cobalt tetroxide and mix for 30 minutes.

[0024] (3) Finally, 3183g of manganese dioxide is added and mixed for 60 minutes.

[0025] (4) Add 3% polyvinyl alcohol for granulation, and the moisture content is 12%.

[0026] (5) Dry the pellets at 100°C, fully dry and sinter it, increase the temperature from room temperature to 350°C for 1 hour, keep it at this temperature for 4 hours, then raise it to 950°C for 5 hours, then lower it to 650°C for 2 hours and keep it for 15 hours. Cool down naturally.

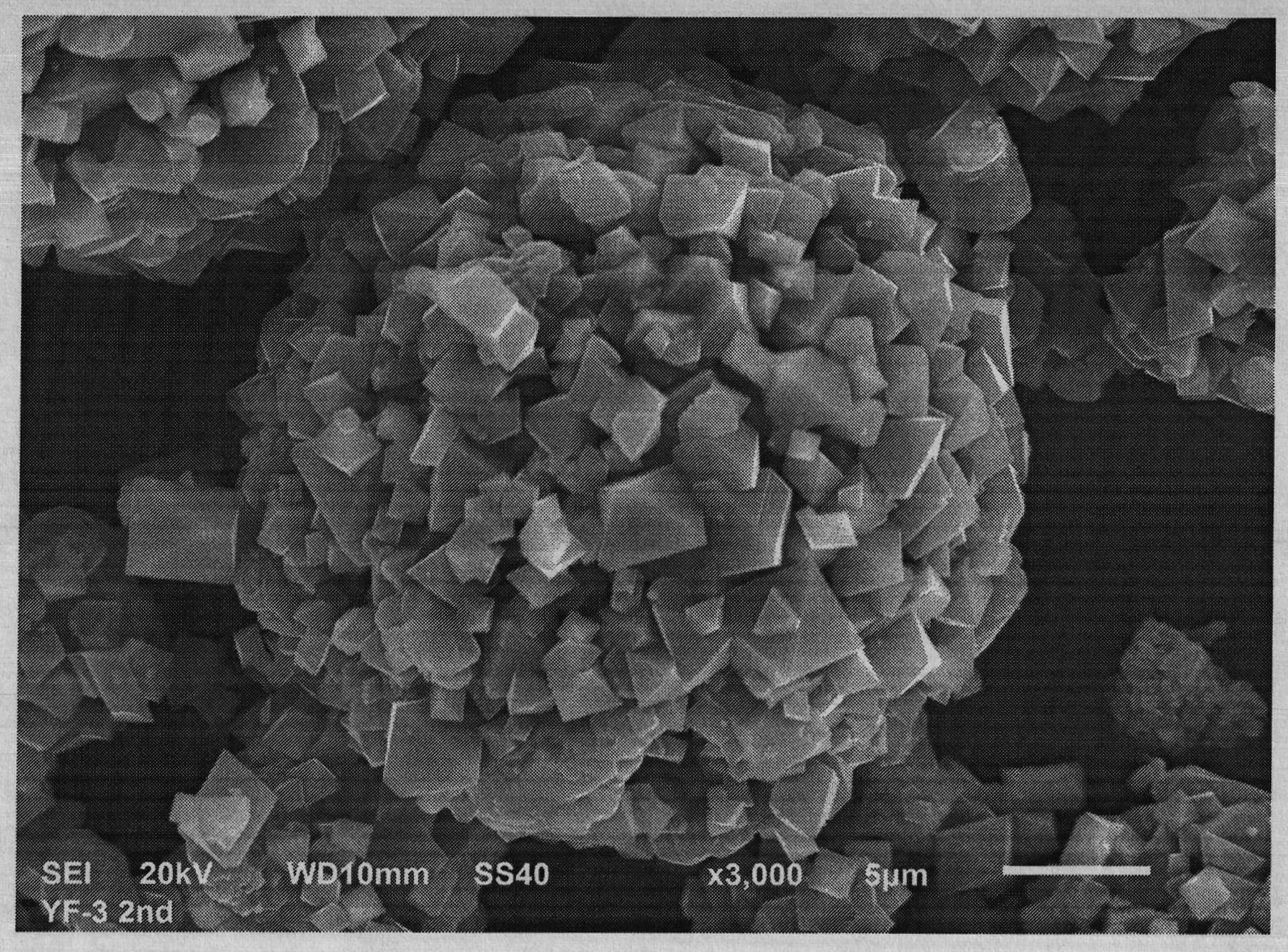

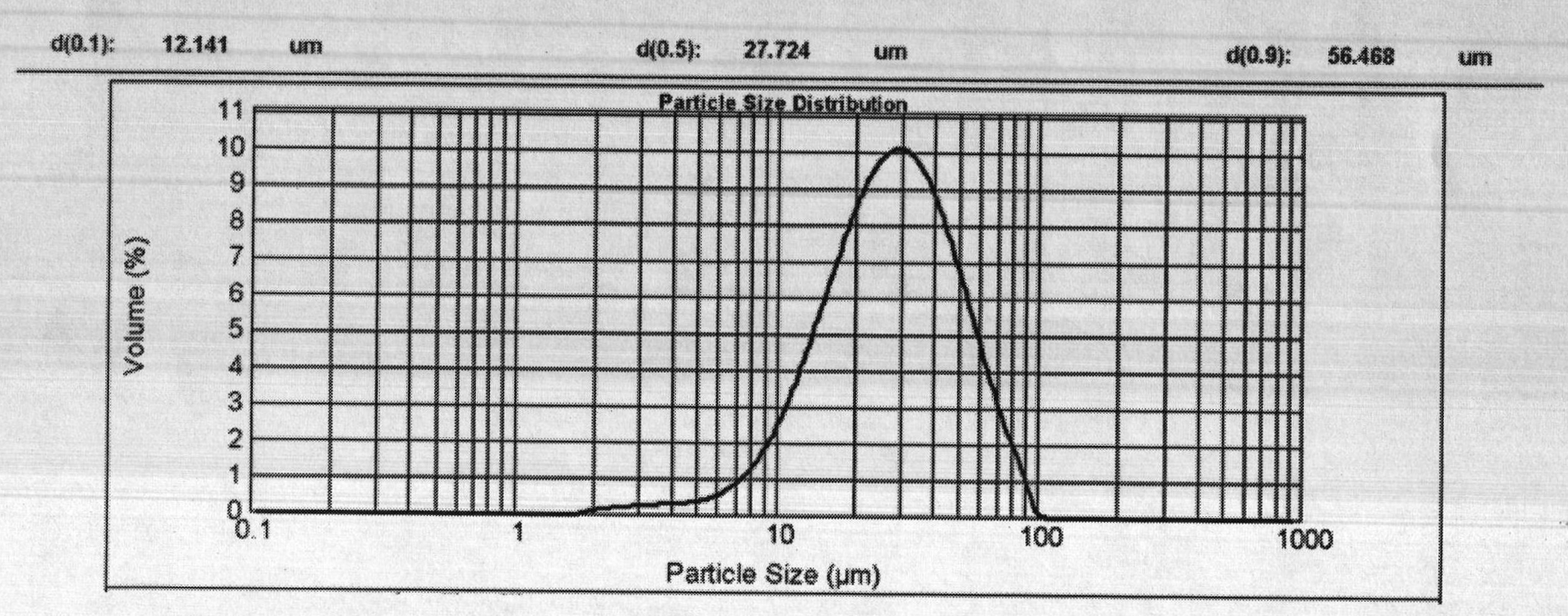

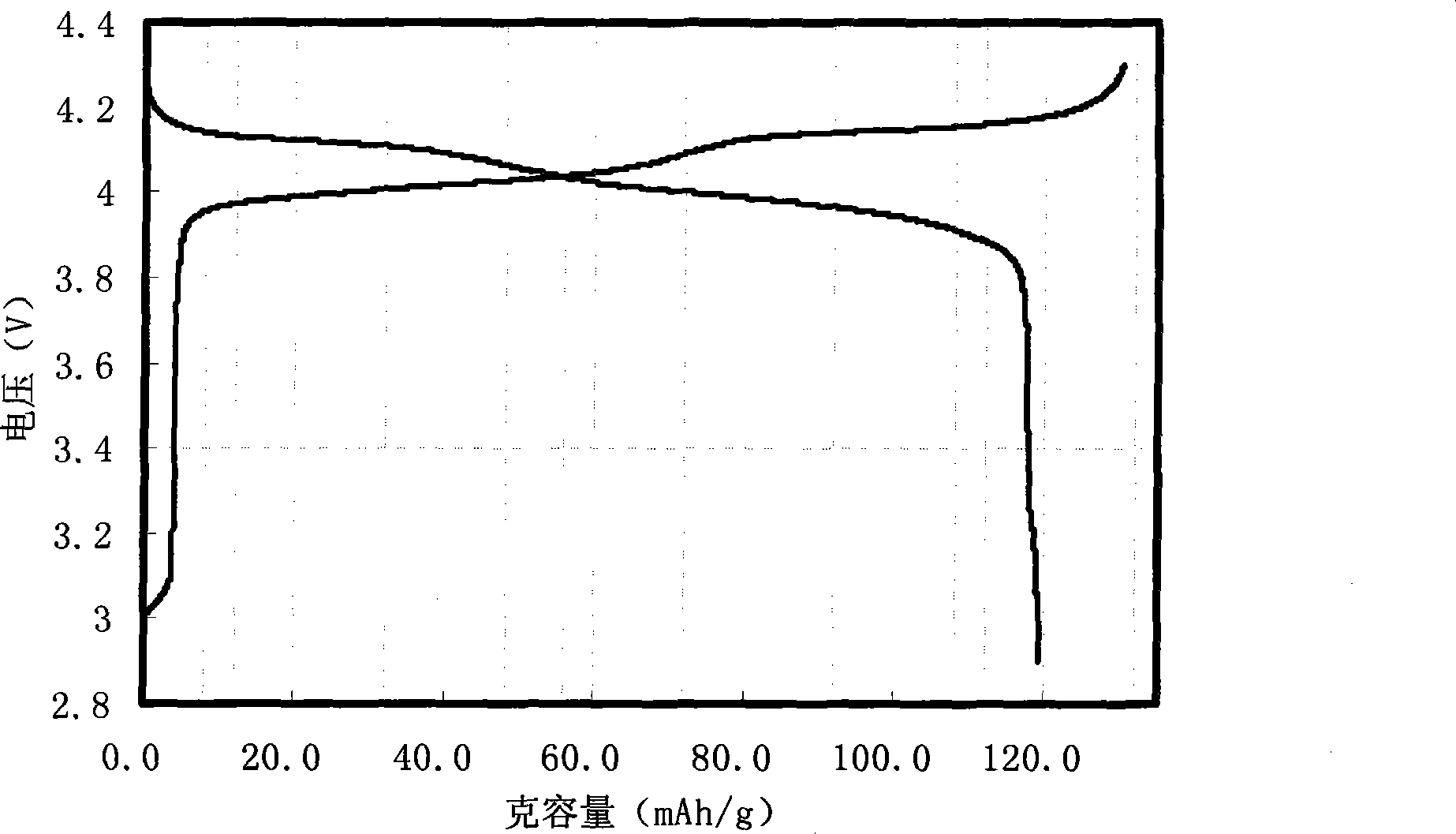

[0027] (6) The calcined material is broken, sieved, and various performance tests are performed. The results are as follows Figure 1-Figure 3 Shown.

Embodiment 2

[0029] (1) Weigh 686 g of lithium hydroxide and 48 g of cobalt tetroxide into a high-speed mixing granulator and mix for 20 minutes.

[0030] (2) Add 36 g of aluminum hydroxide and mix for 20 minutes.

[0031] (3) Finally, add 3118g of trimanganese tetroxide and mix for 40 minutes.

[0032] (4) Add 3% polyvinyl alcohol for granulation, and the moisture content is 15%.

[0033] (5) Dry the pellets at 150°C, fully dry and sinter it, increase the temperature from room temperature to 350°C for 1 hour, keep it at this temperature for 4 hours, then raise it to 950°C for 5 hours, then lower it to 650°C for 2 hours and keep it for 15 hours. Cool down naturally.

[0034] (6) The calcined materials are broken, sieved, and various performance tests are performed.

Embodiment 3

[0036] (1) Weigh 729 g of lithium nitrate and 60 g of aluminum hydroxide into a high-speed mixing granulator and mix for 10 minutes.

[0037] (2) Add 48 g of cobalt tetroxide and mix for 10 minutes.

[0038] (3) Finally, 3183g of manganese dioxide is added and mixed for 30 minutes.

[0039] (4) Add 3% polyvinyl alcohol for granulation, and the moisture content is 14%.

[0040] (5) Dry the pellets at 200°C, fully dry and sinter it, increase the temperature from room temperature to 350°C for 1 hour, keep it at this temperature for 4 hours, then raise it to 950°C for 5 hours, then lower it to 650°C for 2 hours and keep it for 15 hours. Cool down naturally.

[0041] (6) The calcined materials are broken, sieved, and various performance tests are performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com