Liquid-cooling and gas-cooling air-diesel gas generators and application thereof

A gas generator and air technology, applied in applications, mining fluids, household appliances, etc., can solve the problem that heat dissipation loss can not be effectively taken into account, and achieve the effect of good regenerative cooling effect, high safety, and unique structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

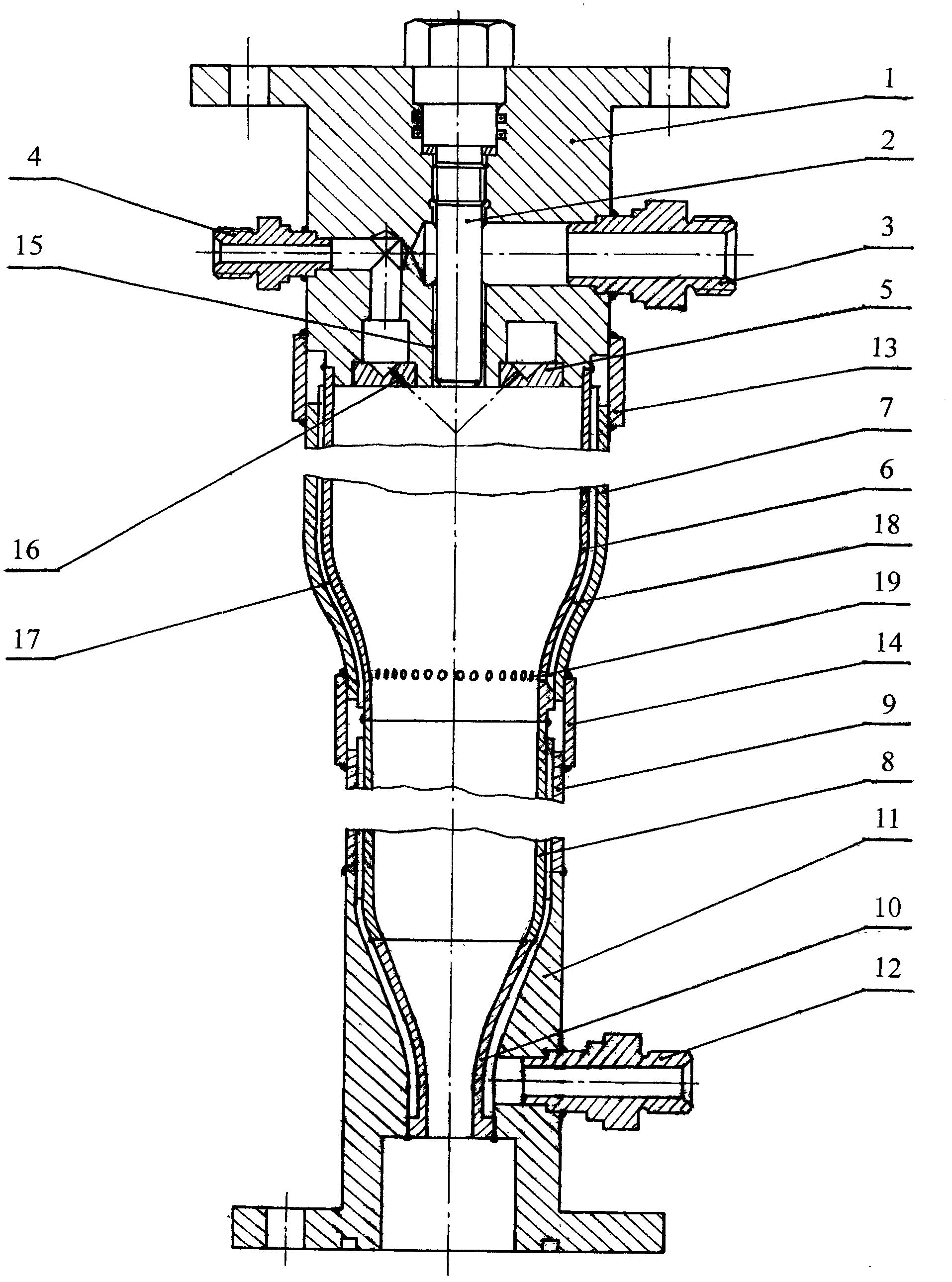

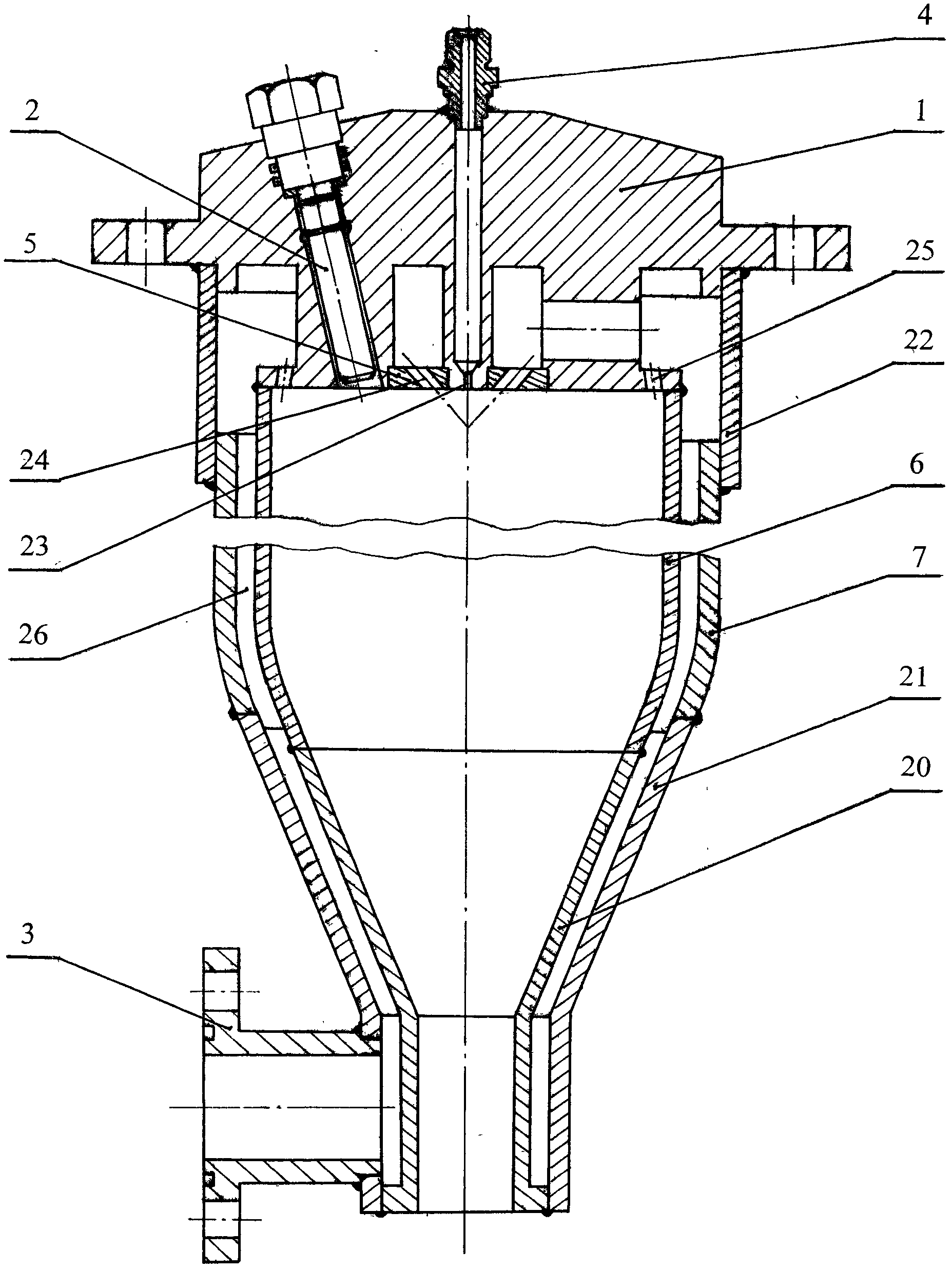

[0018] figure 1 and figure 2 —— Figure 6 It is two preferred implementation structures of the present invention.

[0019] Such as figure 1 As shown, a liquid-cooled air diesel gas generator of the present invention includes a head seat 1, an electric spark plug 2, an air nozzle 3, a fuel nozzle 4, a panel 5, a combustion inner wall 6, a combustion outer wall 7, a mixing Inner wall 8, mixing outer wall 9, axisymmetric nozzle inner wall 10, nozzle shell 11, coolant nozzle 12, straps 13 and 14. Thirteen heat-resistant stainless steel parts are welded into one except the outsourcing electric spark plug 2 of screw connection. For thermal oil recovery, in addition to injecting hot gas and liquid flow into the oil well for a long time, it can also work intermittently: alternately inject hot gas and liquid flow and cold air every 12-24 hours. The panel 5 is provided with an oblique-hole fuel nozzle 16 forming a ring-shaped oblique-hole injection unit with the annular air nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com