System and method for machining LED (light-emitting diode) substrate by laser

A laser processing and substrate technology, applied in the direction of laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of thermal damage, low processing efficiency, high production cost, etc., to reduce production costs, improve production efficiency, and improve light output Effects on Efficiency and Production Yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

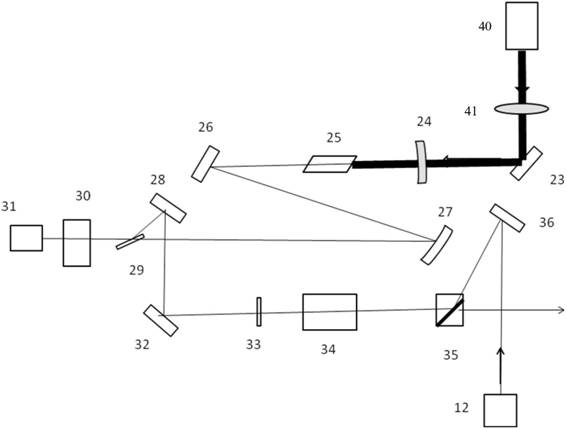

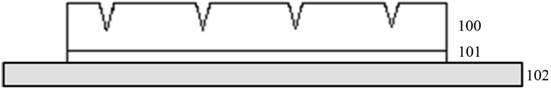

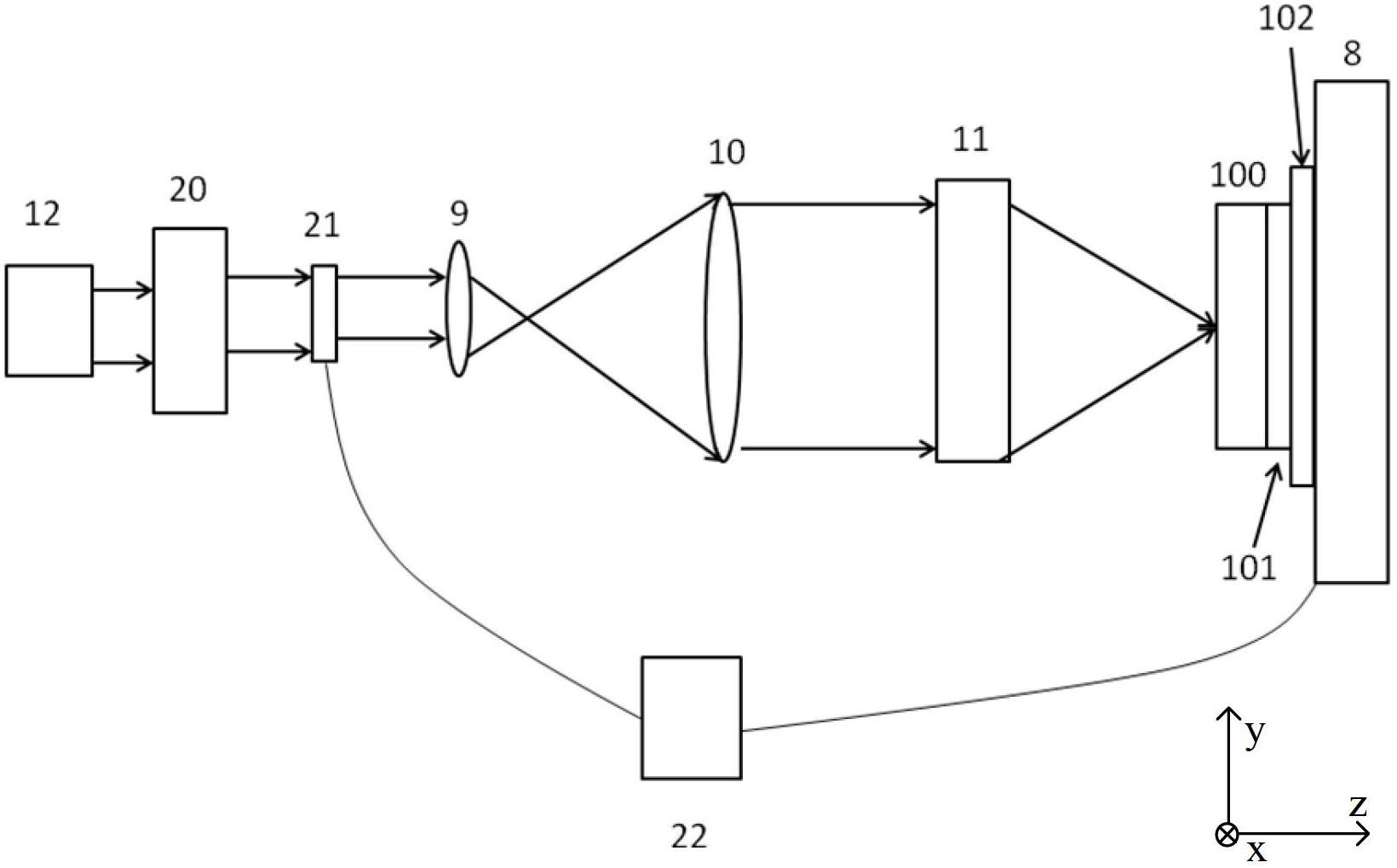

[0057] figure 1 The system for laser processing LED substrates of this embodiment is shown, including: a femtosecond pulse seed laser source 12, a laser amplification beam expansion device (including a laser amplifier 20, an optical gate 21, a beam expansion lens combination device, and a cylindrical lens 11) , the bearing part 8, and the synchronous controller 22.

[0058] Wherein, the femtosecond pulse seed laser source 12 is used to emit femtosecond pulse laser. As a non-limiting example, the femtosecond pulse seed laser source 12 in this embodiment can be realized by a mode-locked fiber femtosecond laser, and the specific parameters are as follows: the pulse width is between 20 ~ 150fs, the center wavelength is 800nm, and the repetition rate is 20~80MHz, the puls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com