Selective urea decomposition catalyst taking honeycomb metal alloy as carrier and preparation method for catalyst

A honeycomb metal and catalyst technology, which is applied in the field of urea selective decomposition catalyst and its preparation, can solve the problems of insufficient low-temperature light-off property, poor temperature stability of catalytic active coating, etc., and achieves good low-temperature light-off property, The effect of good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] First prepare the carrier coating sol, mix 3.4kg butyl titanate with 0.92kg absolute ethanol, and stir for 2 hours as A solution; 0.43kg cerium nitrate is added to 0.18kg deionized water, then add 0.29kg pyrophosphoric acid ( 45wt%), then stirred for 2 hours as solution B; while stirring, solution B was added to solution A at a rate of 80ml / min, and then stirred for 2 hours to obtain 5.22kg of uniform and stable carrier coating sol.

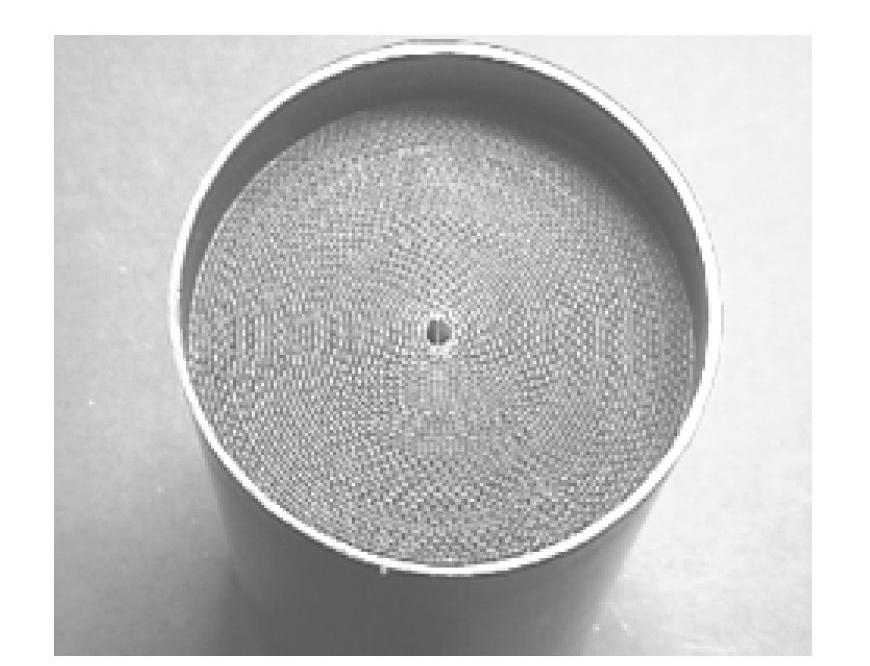

[0041] In order to facilitate the better adhesion of the carrier coating to the carrier, the Fe-Cr-Al honeycomb metal alloy carrier (diameter 34cm, height 10cm, mesh number 350 mesh) coated with glass coating was completely immersed in the previously prepared In the carrier coating sol, it was taken out after immersion for 30 minutes and purged with nitrogen gas to make the pores of the carrier unobstructed.

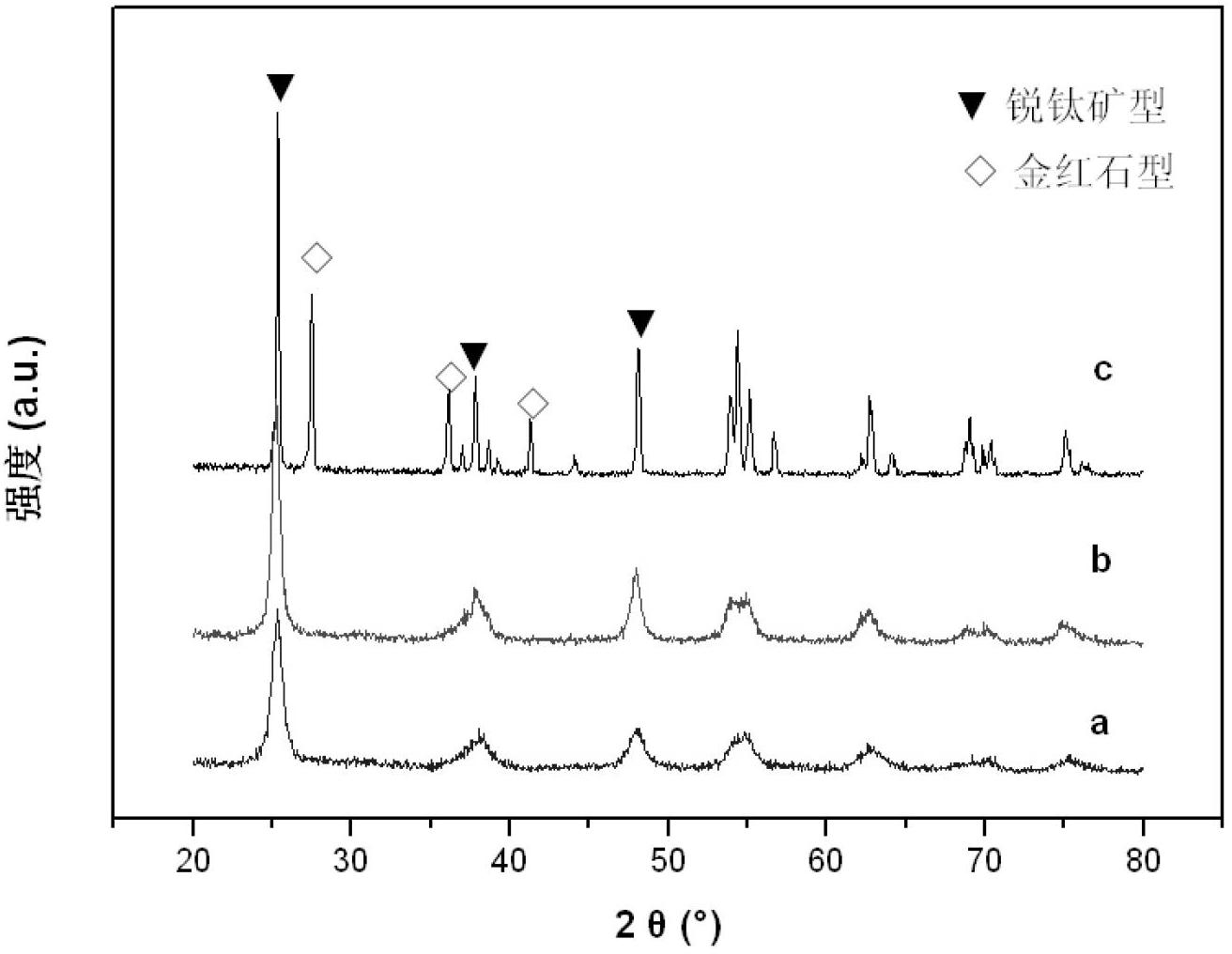

[0042] Subsequently, it was dried in a drying oven at 80° C. for 12 hours, then calcined at 500° C. for 2 hours, and finally the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com