Method for casting large-grained silicon ingot

A large-grain, silicon ingot technology, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve the problems affecting the photoelectric conversion rate of batteries, high photoelectric conversion rate of batteries, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The single crystal bar with (100) crystal orientation obtained by the Czochralski method is cut according to a certain direction to make a single crystal silicon plate as a seed crystal. The shape of the monocrystalline silicon plate can be a long plate with a length of 720mm-800mm, a width of 125mm-200mm, and a thickness of 10mm-30mm.

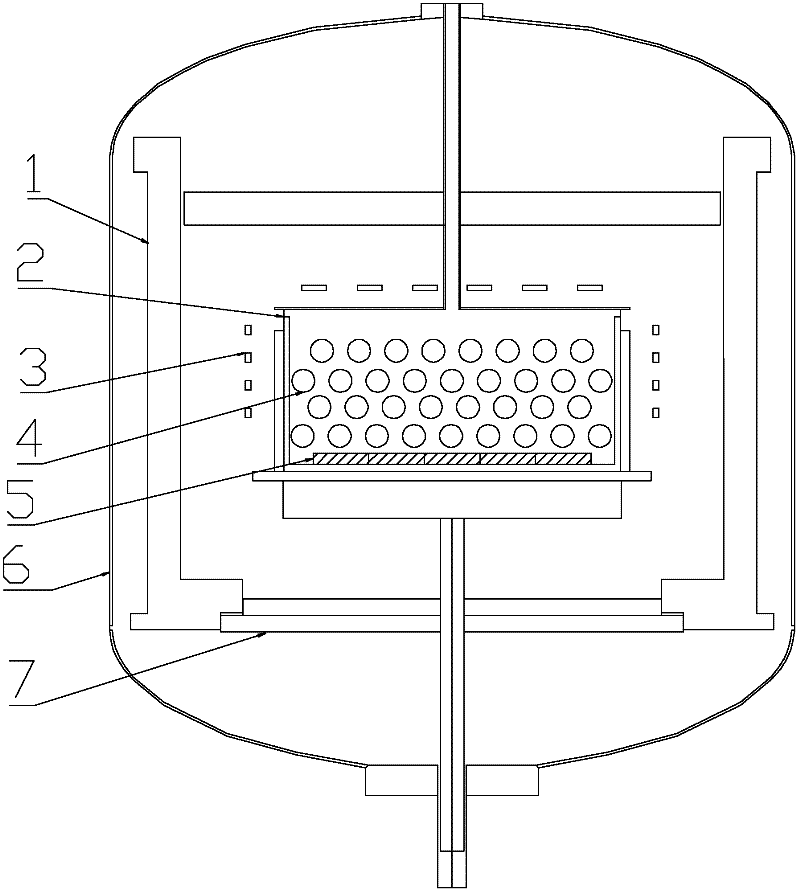

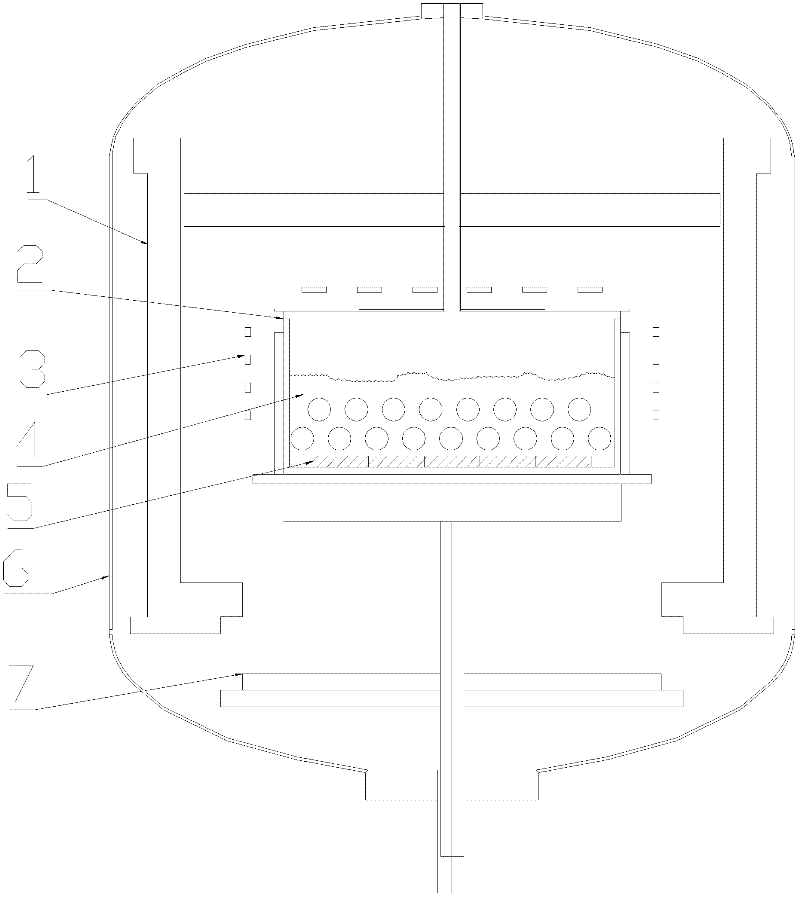

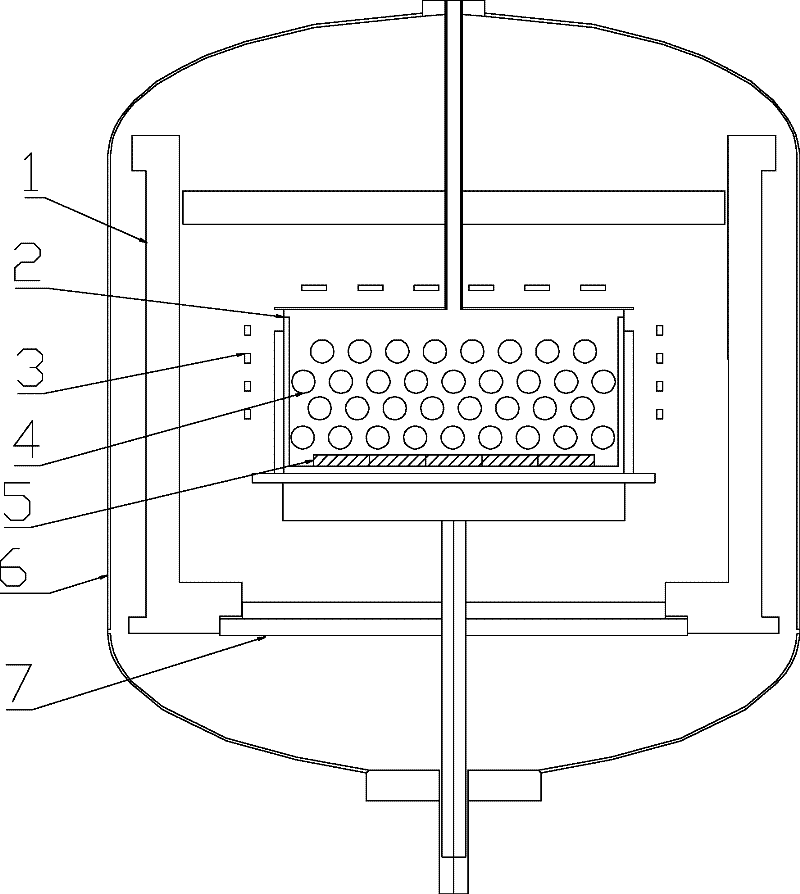

[0018] like figure 1 and figure 2 As shown, select a quartz crucible 2 of a standard size, select 5 above-mentioned monocrystalline silicon plates 5 and place them flat on the bottom of the crucible, and add an appropriate amount of doping elements such as boron or phosphorus according to the requirements of the target resistivity of 1-3 ohm / cm , fill the polysilicon material 4 above the single crystal plate 5; put the crucible 2 with the raw material into the polysilicon furnace 6, vacuumize and heat, and control the temperature of the heater 3 to be 1420-1550 ° C, so that the polysilicon on the upper part of the seed crystal The ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com