Method and device for growing silicon carbide crystal according to PVT (Physical Vapor Transport) method

A silicon carbide and crystal technology, applied in the field of growing silicon carbide crystals by PVT method, can solve various crystal defects and difficulties in growing high-quality crystals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

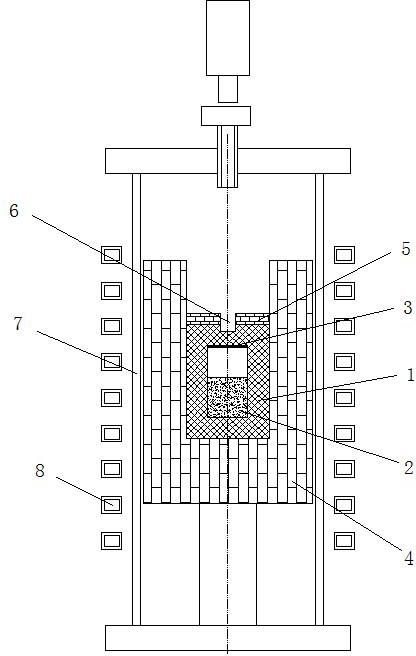

[0039] (1) if Figure 5 As shown, on the top of the graphite crucible cover, an adiabatic moving adjusting element 9 made of solid carbon (graphite) felt or soft (graphite) carbon felt is added to regulate the heat flow, and the movable adiabatic adjusting element 9 is suspended on the graphite The lower end of the connecting rod. The connecting rod is connected with the precision linear motion system installed outside the vacuum furnace described in the following (2) through the vacuum dynamic sealing junction. When growing crystals, the movable heat insulating adjustment element 9 can be moved according to the process requirements to change the heat preservation effect above the crucible to offset the influence of the increase in crystal thickness on the temperature of the growth surface.

[0040] (2) The equipment used in the embodiment such as Figure 5 As shown, it includes a vacuum chamber composed of a high-purity recrystallized alumina tube and upper and lower sealin...

Embodiment 2

[0058] (1) The growth equipment used in Example 2 is the same as that described in (1), (2), (3) and (4) in Example 1.

[0059] (2) The inner hole diameter of the graphite crucible used for crystal growth is 78mm, the inner hole height is 140mm, and the outer diameter is 140mm. It is made of high-purity, high-density, high-strength graphite.

[0060] Put 800 grams of silicon carbide polycrystalline powder with a particle size of 0.1 to 2 mm and a purity of more than 4 nines in the crucible.

[0061] The seed crystal used is a silicon carbide single wafer with a diameter of 76.2mm and a thickness of about 0.3-0.5mm, which is pasted on the inner surface of the upper cover of the graphite crucible.

[0062] The insulation parts on the periphery and bottom of the graphite crucible are made of high-purity solid carbon felt or soft carbon felt, with a diameter of 280--300mm and a height of 480mm. There is a hole coaxially in the middle for placing the graphite crucible: the diamete...

Embodiment 3

[0073] (1) The growth equipment used in Example 3 is the same as that described in (1), (2) and (3) in Example 1. However, a larger vacuum furnace and induction coil are used.

[0074] (2) The inner hole diameter of the graphite crucible used for crystal growth is 106, the inner hole height is 160mm, and the outer diameter is 190mm, which is made of high-purity, high-density, high-strength graphite.

[0075] Fill the crucible with 1600 grams of silicon carbide polycrystalline powder with a particle size of 0.1 to 2 mm.

[0076] The seed crystal used is a silicon carbide single wafer with a diameter of 101.6mm and a thickness of about 0.3-0.5mm, which is pasted on the inner surface of the upper cover of the graphite crucible.

[0077] The insulation parts on the periphery and bottom of the graphite crucible are made of high-purity solid carbon felt or soft carbon felt, with a diameter of 300mm and a height of 520mm. There is a hole for placing the graphite crucible coaxially ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com