Illumination system of a microlithographic projection exposure apparatus

An illumination system, microlithography technology, applied in the system field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] I. Overall structure of projection exposure equipment

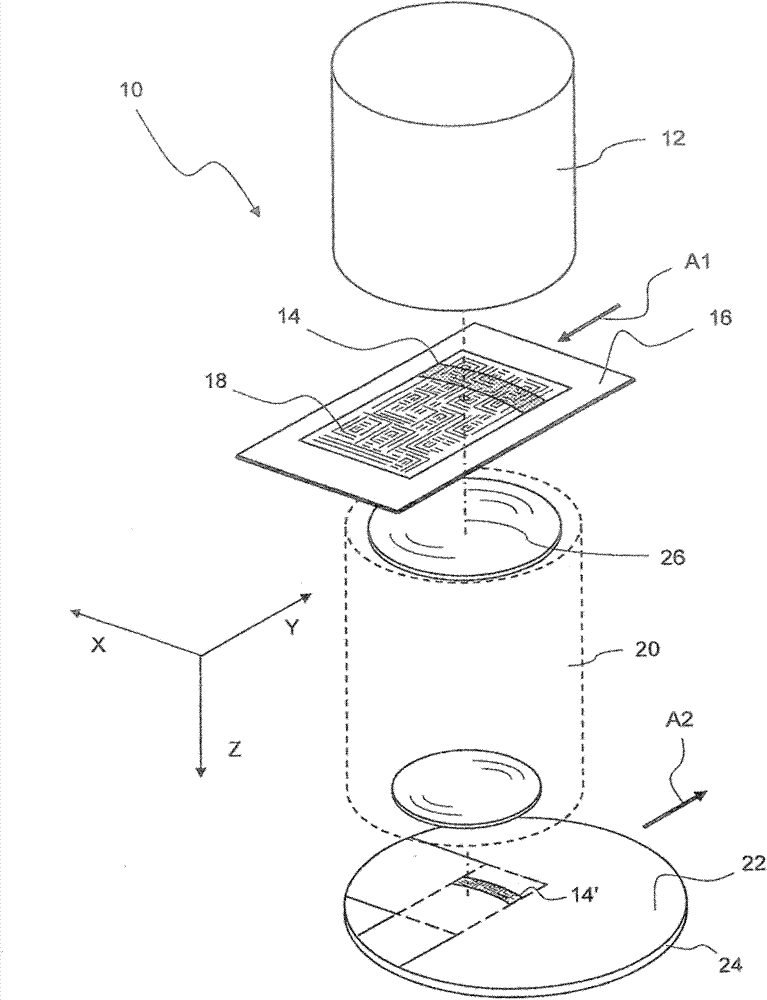

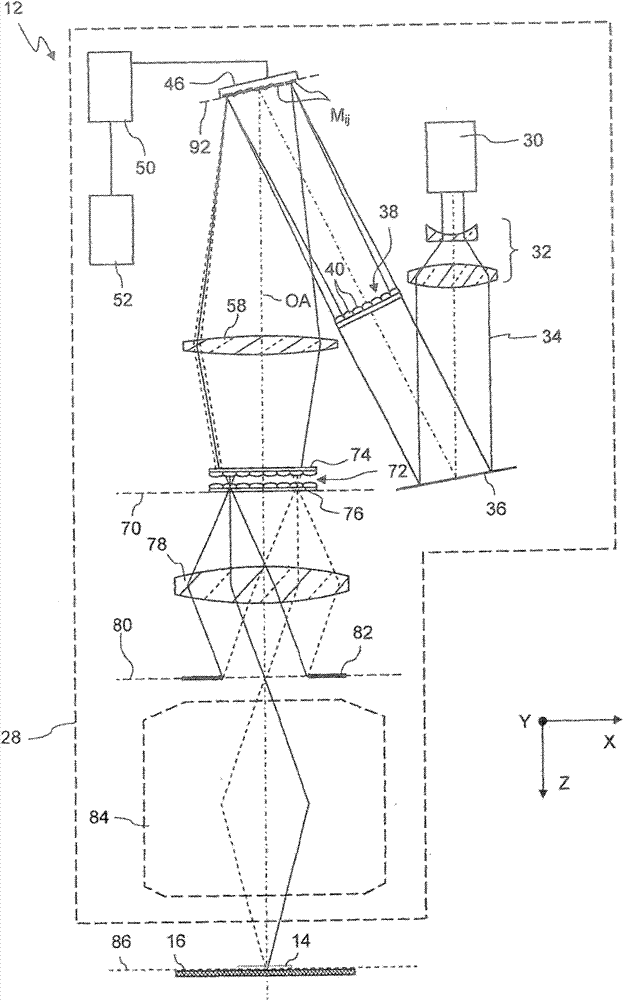

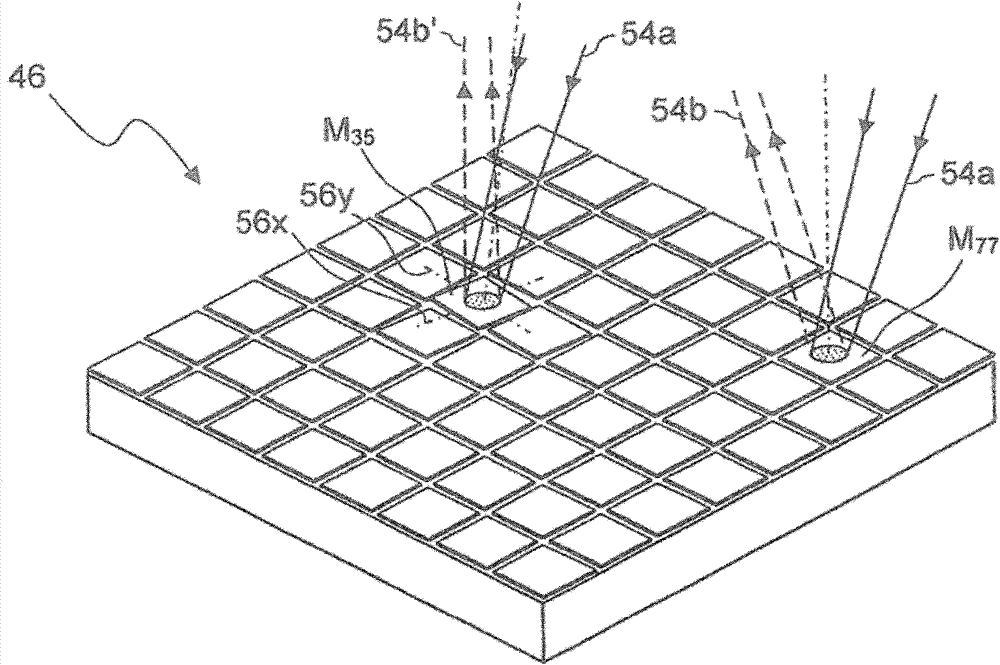

[0054] figure 1 is a perspective and highly simplified view of a projection exposure apparatus 10 comprising an illumination system 12 for generating a projection beam. The projected beam illuminates a field 14 on a mask 16 containing minute structures 18 . In this embodiment, the illuminated field 14 has approximately the shape of a ring segment. However, other (for example rectangular) shaped illumination fields 14 can also be designed, for example.

[0055] The projection objective 20 images the structure 18 within the illuminated field 14 onto a light sensitive layer 22 , such as photoresist, which is deposited on a substrate 24 . Substrate 24 , which may be formed from a silicon wafer, is placed on a wafer stage (not shown) such that the top surface of light-sensitive layer 22 is precisely positioned in the image plane of projection objective 20 . The mask 16 is positioned in the object plane of the projec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com